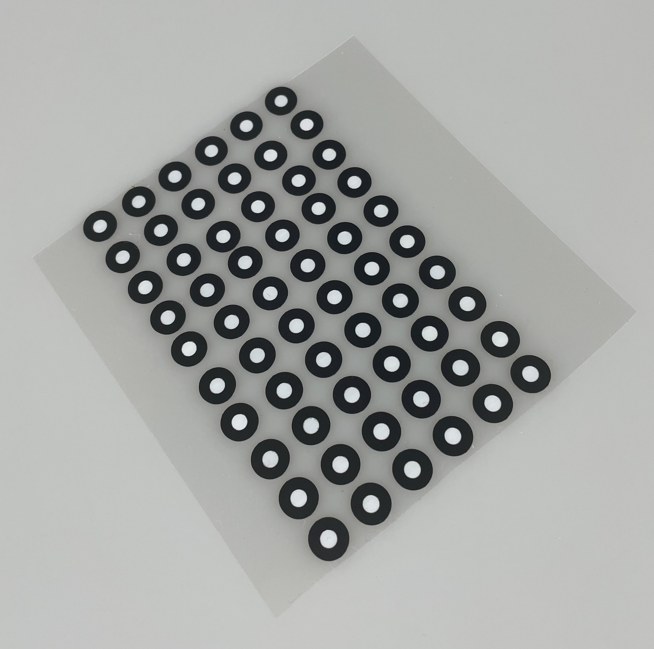

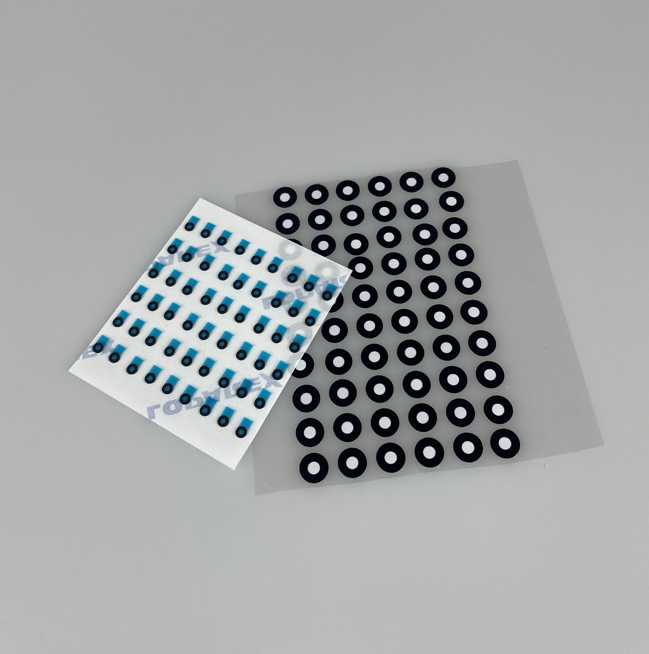

acoustic membrane

The acoustic membrane represents a breakthrough technology in sound transmission and audio engineering applications. This innovative component serves as a critical interface between acoustic energy and electronic systems, converting sound waves into electrical signals with exceptional precision. An acoustic membrane functions primarily as a transduction element that captures sound vibrations and transforms them into measurable data for various audio processing applications. The core functionality revolves around its ability to respond to pressure variations in air, making it indispensable for microphones, speakers, and acoustic sensors. Modern acoustic membranes incorporate advanced materials such as polymer films, ceramic composites, and specialized metal alloys that enhance their sensitivity and frequency response characteristics. The technological features include ultra-thin construction, typically measuring between 10 to 100 micrometers in thickness, which enables rapid response to sound pressure changes. These membranes exhibit remarkable durability while maintaining consistent performance across wide temperature ranges and humidity conditions. Applications span numerous industries including consumer electronics, automotive systems, medical devices, and professional audio equipment. In smartphones and tablets, acoustic membranes enable voice recognition and noise cancellation features. The automotive sector utilizes these components for hands-free communication systems and active noise control in luxury vehicles. Medical applications include hearing aids and diagnostic equipment where precise sound capture is essential. Professional audio equipment relies on acoustic membranes for studio-grade recording and live sound reinforcement systems. The manufacturing process involves precise material selection, controlled environment production, and rigorous quality testing to ensure optimal performance. These membranes can be customized for specific frequency ranges, sensitivity levels, and environmental requirements, making them versatile solutions for diverse acoustic challenges across multiple industries and applications.