microvent acoustic membrane

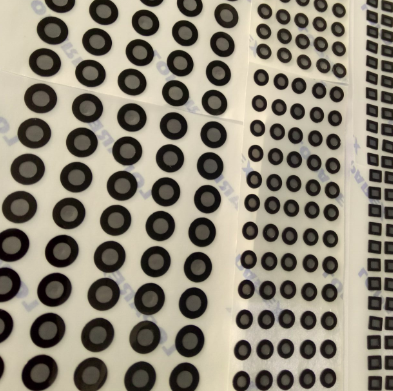

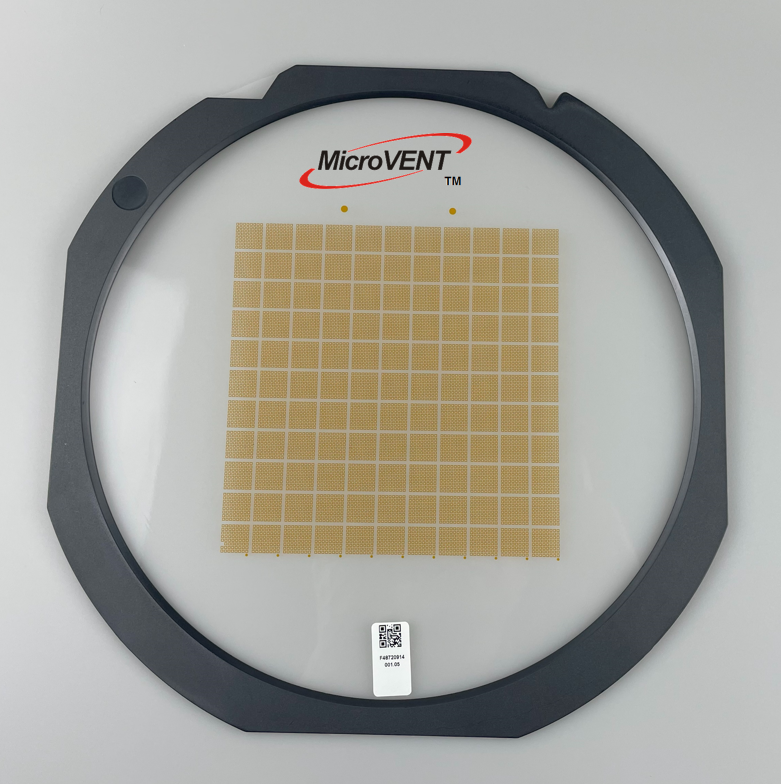

The microvent acoustic membrane represents a revolutionary advancement in sound management technology, designed to optimize acoustic performance while maintaining essential ventilation capabilities. This sophisticated component serves as a critical barrier that selectively manages sound transmission without compromising airflow requirements in various electronic devices and enclosures. The microvent acoustic membrane functions primarily as a protective element that prevents dust, moisture, and contaminants from entering sensitive equipment while allowing controlled air exchange. Its innovative design incorporates microscopic pores that create an effective acoustic seal, significantly reducing unwanted noise transmission while preserving the necessary ventilation for proper device operation. The technological foundation of the microvent acoustic membrane relies on advanced materials engineering, utilizing specialized polymers and membrane structures that respond differently to sound waves versus air movement. This selective permeability ensures optimal performance in demanding environments where both acoustic control and environmental protection are essential. The membrane's construction typically features multiple layers, each engineered to address specific acoustic frequencies and environmental challenges. Modern microvent acoustic membrane technology employs cutting-edge manufacturing processes that create consistent pore structures, ensuring reliable performance across temperature variations and extended operational periods. These membranes find extensive applications in consumer electronics, automotive systems, telecommunications equipment, and industrial machinery where noise reduction is critical. The versatility of the microvent acoustic membrane makes it suitable for integration into smartphones, tablets, speakers, headphones, and various portable devices. In automotive applications, these membranes help reduce cabin noise while maintaining proper ventilation for electronic components. The telecommunications industry relies heavily on microvent acoustic membrane technology to enhance call quality and reduce background interference in communication devices. Industrial applications benefit from the membrane's ability to protect sensitive equipment from harsh environmental conditions while maintaining acoustic performance standards.