Understanding the Role of Vent PE Liners in Packaging

What Are Vent PE Liners?

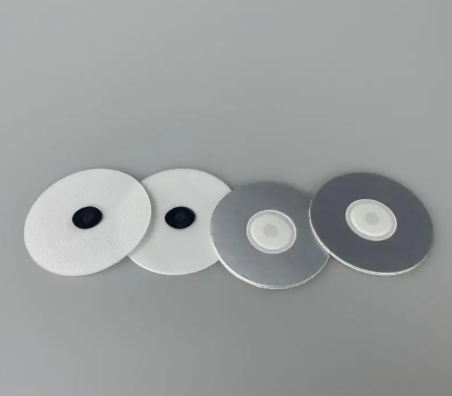

Vent PE Liner Incorporates a unique form of packaging to improve performance by allowing reverse gas exchange but keeping out contaminants. They are unlike older liners which sealed completely and led to potential problems such as moisture. Their risk of being polluted by being in a limited access vessel that allows free passage of air is reduced by use of Vent PE Liners which is of particular interest in industries where maintaining the quality of contents is strict requirement. As it is apparent in so many areas from food and drugs to agriculture and industry, their value transcends all industries.

Core Components and Material Science Behind PE Liners

Vent PE Barrier Liners are based on polyethylene, an extraordinary material with untold flexibility, resilience, and resistance to a multitude of environmental influences. The present invention offers important advantages. Because poly is so flexible and pliable, the liners can accommodate various packaging configurations and the not-so-perfect volumes, targeting the risk of pokes or tears. Additionally, the tensile strength of the material lends itself to extended longevity over the years, even during aggressive use in challenging environments. The material science principle: permeability, tensile strength are combined to bring liners that are not only protective but preserve the quality of goods stored in them during transit or storage.

Key Mechanisms of Vent PE Liners for Performance Enhancement

Pressure Equalization and Gas Exchange

Vent PE liners are instrumental in promoting even pressure within packaging. These liners help to avoid bulging or melting that can happen on the way. Moreover, Vent PE liners are designed to assure a sufficient gaseous exchange, which is an essential prerequisite for keeping the quality of organic products. These liners, especially if ‘breathable’ support a longer shelf life of products- knowing that air can remain. In studies, evidence supports this benefit with better freshness and shelf life of goods packed with Vent PE liners as a result of efficient gas management.

Moisture Control and Contamination Prevention

And the moisture management of Vent pe liner is a highlight. These liners help diminish spoilage by with ensuring a good humidity balance in the product packaging. At the same time, they serve as a protectant against contaminants so that foreign substances will not be able to get into packaging products. The special construction enables airflow, while safeguarding your palms, the best of both worlds. It appeared however that the spoilage rates of product packed with Vent PE liners were much lower than those packed with non-ventilated liners which indicates that the liners assist in maintaining product quality.

Benefits of Vent PE Liners Across Packaging Applications

Extending Shelf Life of Perishable Goods

Vent PE Liners are an integral part in preserving the freshness of perishable items including fruits, vegetables and dairy products. These liners allow air to flow freely, preventing moisture build-up, the main cause of spoilage. One well known food industry case study showed a reduction of decay rate during transport of the product when the liners were utilized and they maintained an appearance of freshness. A range of measures, including lower spoilage rates and consumer satisfaction surveys, provide methods to quantify the shelf life extension of Vent PE Liners in line with best practice in quality and sustainability for the industry.

Reducing Product Damage During Transportation

Vent PE Liners are indispensable for preventing damage to your value of products in transportation, the cushioning effect of liner and vent PE film will also allow your product to breathe themselves. This protective characteristic significantly lowers product damage during shipping, as demonstrated in data of lower return rates when goods are shipped with this liner. In the shipping world, we observe these liners continue to be the only reliable indicator in reducing damage and hence building customer confidence and trust. Durable liners to protect contents, the sturdy construction reinforces the liners' strength when dealing with real-world transport scenarios.

Improving Safety in Chemical and Hazardous Material Packaging

Vent PE Liners are the ultimate choice for containment of chemical and hazardous applications when you need to stop leaks and allow gasses to diffuse. This new function is essential to meet strict safety regulations and in prevention of potentially hazardous contamination episodes. Test results by industry experts support the efficiency of the liners, with a financial benefits of increased safety in chemical packaging because of advanced design. They can be far used not only in common packing but also more special application to keep the dangerous items away from the leak and the pollution of industrial environment and ecology.

Vent PE Liners vs Traditional Packaging Solutions

Superior Breathability Compared to Solid Liners

Vent PE Liner provides much greater breathability compared to conventional solid liners which is especially useful for items that require air flow, such as perishables. With an increase in oxygen flow, Vent PE Liners keep fruits and vegetables fresh from the moment they are picked, as some produce can be extremely sensitive to oxygen levels. As opposed to solid liners which completely seal, Vent PE Liners allow gases to pass through under control,helping to prevent condensation in the packaging. For example, packaging with Vent PE Liners experiences less dampness and spoilage as that of solid liners.

Cost-Efficiency Through Reduced Waste and Returns

By minimizing product spoilage and damage, Vent PE Liner allow hefty cost savings in the end, making it a cost-effective solution. “Industry sources report that implementing advanced packaging solutions such as Vent PE Liners results in a significant reduction in both returns and repacking,” Stupak says. The liners’ capacity to inhibit package failures that result from bloating and paneling minimizes the amount of product that does not meet standards, helping to reduce the expense these problems can exact on those who conduct business. With the adoption of Inserts designed for Vent PE Liners, companies not only achieve waste reduction, but also protect their reputation, seeing their products arrive at destination in perfect condition and reducing the impact of handling in terms of return.

Industry-Specific Applications of Vent PE Technology

Food & Beverage: Maintaining Freshness in Flexible Packaging

Vent PE Liners: also know as vent plugs are now an increasingly important tool in the food and beverage market and provide excellent benefits for flexible packaging applications. The breathable nature of these liners is critical to preserving the freshness of food items, by enabling air to circulate so that as little moisture as possible has the chance to enter and spoil the products. This balance is what allows foods like fruits, vegetables, and baked goods to keep fresh the longest--it prolongs shelf life while also reducing spoilage. From a stock management perspective, the use of Vent PE Liner has helped improve turnover. This way, businesses can better control inventory levels and avoid the waste and financial costs of expired stock. The inclusion of these liners mean that quality is guaranteed for consumers and logistics can be made more efficient up and down the supply chain.

Pharmaceuticals: Ensuring Sterility in Medical Device Containers

The pharmaceutical industry relies heavily on Vent PE Liners to preserve sterility inside medical device containers. These liners offer a breathable, but non-permeable, barrier preventing contamination, a must-have attribute when maintaining the integrity of pharmaceuticals and medical devices in storage and transport. Compliance is also a critical factor in this application, with Vent PE Liners helping to comply with tough industry health & safety standards as they prevent bacteria growth and protect delicate materials. The use of such high-grade packaging solutions in the medical field emphasizes the significance of Vent PE Liners in maintaining product sanctity while being in compliance with the stringent regulations.

Agriculture: Protecting Fertilizers and Pesticides from Degradation

For agriculture, use of VENT PE LINERS is vital in preventing fertilizers and pesticides from losing efficacy due to moisture degradation. These insulating liners manage the moisture to prevent humidity-induced degradation of chemical properties. It has been found that whenever fertilizers and pesticides are packed with Vent PE Liners, they keep their action and potency longer, retaining the desired efficacy and economics. This is of paramount importance since rural communities has contributed an impressive amount of financial investment in agricultural inputs. By protecting these products, Vent PE Liners help these products last and work to save natural resources and the environment by improving efficiencies and cutting the waste.

FAQ Section

How Does a Vent PE Liner Improve Packaging Performance?

Vent PE Liners improve packaging performance by allowing for gas exchange and maintaining pressure equalization, which helps prevent spoilage, bulging, and product damage. Additionally, they offer moisture control and contamination prevention benefits, ensuring the quality and safety of packaged contents.

What are the core benefits of using Vent PE Liners?

The core benefits include extending shelf life, reducing product damage during transportation, improving safety in chemical packaging, and providing superior breathability compared to traditional solid liners, which all contribute to cost-efficiency by reducing waste and returns.

In which industries are Vent PE Liners most effective?

Vent PE Liners are most effective in industries such as food & beverage, pharmaceuticals, and agriculture, where they play vital roles in maintaining product freshness, ensuring sterility, and protecting agricultural inputs from degradation.

EN

EN

AR

AR

CS

CS

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

ID

ID

VI

VI

TH

TH

TR

TR

MS

MS