The Critical Role of Packaging Valves in Industrial Efficiency

How Valve Technology Impacts Product Integrity

Valve technology plays an essential role in maintaining product integrity, ensuring safety and quality during storage and transportation. Advanced valve designs are critical as they offer durable solutions that protect against environmental factors. Their ability to seal tightly prevents contamination and spoilage, a necessity in industries handling perishable items like food and pharmaceuticals. Packaging valves, when designed to adhere to industry quality assurance standards, provide a robust defense against external threats.

Additionally, effective sealing mechanisms have been proven to significantly enhance product shelf life. Studies highlight that products packed with high-quality valves can experience a notable increase in longevity. This is attributed to the precision in air and moisture barrier capabilities that these valves provide, ensuring product freshness and safety even over extended periods. As a result, valve technology doesn't just contribute to packaging efficiency; it directly impacts a business's bottom line by reducing spoilage and maintaining product quality.

Addressing Common Challenges in Packaging Seals

Packaging systems often face challenges such as leakage and pressure loss, which can lead to significant industry losses. Statistics reveal that these issues can cause millions in damage to products annually. Leakage compromises product quality and can lead to spoilage, thus highlighting the importance of a reliable sealing solution. Pressure loss is another prevalent issue, which impacts the integrity of the packaging and can result in the deterioration of the product inside.

Innovative valve designs offer solutions to these common challenges, enhancing overall packaging reliability and efficiency. By integrating advanced technology, these valves ensure a secure seal that prevents leakage and maintains consistent pressure within the packaging. Experts agree that selecting the right sealing technology is crucial to overcoming these industry challenges. The adoption of improved valve technologies not only mitigates these problems but also boosts operational efficiency and product security, ensuring that packaging solutions remain robust and cost-effective.

MicroVent® Valves: Engineering Breakthroughs in ePTFE Solutions

Proprietary Porous Membrane Design

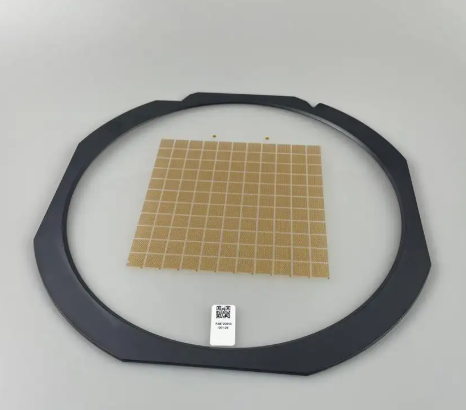

MicroVent® valves are engineered with a proprietary ePTFE porous membrane design that offers significant advantages in packaging applications. The unique properties of ePTFE, including its microporous nature, ensure superior ventilation without compromising the closure integrity. This allows packaging systems to maintain optimal product safety by preventing any buildup of pressure or moisture while still allowing air to flow freely. Technical research affirms the efficacy of this design, demonstrating its ability to enhance product storage conditions and extend shelf life significantly. The integration of this technology into the market showcases the practical, effective solutions MicroVent® provides for modern packaging challenges.

Heat Resistance & Chemical Stability Advantages

MicroVent® valves are not only distinguished by their porous membrane design but also by their remarkable heat resistance and chemical stability. These properties make the valves exceptionally suitable for a wide array of industries that require reliable performance under varying environmental conditions. By preventing valve degradation, companies can consistently rely on these valves to function optimally, regardless of the temperature or chemical exposure. Case studies have shown their long-term resilience in challenging environments, reinforcing their value as a robust solution for maintaining packaging integrity over time.

Why Packaging Industries Gain Unique Advantages

Preventing Pressure Fluctuations in Sealed Containers

Maintaining stable pressure in sealed packaging is crucial to prevent potential failures during storage and transport. Pressure fluctuations can lead to ruptures or leaks, compromising the integrity of the package and the quality of the product inside. Effective venting through packaging valves plays an essential role in reducing these risks by allowing excess air or gases to escape, thereby maintaining the structural integrity of the sealed containers. Studies have shown that packaging equipped with advanced valve systems exhibits notably improved pressure stability, reducing incidences of container deformation during transit and handling.

Extending Shelf Life Through Controlled Ventilation

Proper ventilation via packaging valves is a game-changer in extending the shelf life of perishable goods. By regulating the internal environment of a package, these valves minimize the growth of microorganisms and spoilage due to moisture accumulation or gas build-up. For instance, products using advanced valve solutions have been demonstrated to have a longer shelf life compared to those employing traditional sealing methods. Notably, this extension has environmental benefits, as reducing spoilage leads to less waste and a decrease in the carbon footprint associated with producing and disposing of spoiled goods. Embracing these technologies can significantly enhance food preservation strategies and sustainability efforts.

Compatibility With High-Speed Packaging Lines

Packaging valves offer seamless integration into high-speed production environments, ensuring compatibility with automated processes. Their design enhances the efficiency and reliability of operations by reducing downtime and offering consistent performance. In the context of high-speed packaging, automation and reliability are critical to boosting overall operational efficiency. Industry examples have shown a marked improvement in throughput when employing advanced valve technologies, underscoring the importance of selecting the right systems to meet production demands. By integrating these solutions, companies can enhance their production capabilities and maintain high standards of quality across their product lines.

Environmental Compliance and Sustainability Benefits

Meeting Strict EPA Emission Standards

Modern packaging valves play a crucial role in helping businesses meet stringent environmental regulations, particularly the standards set by the Environmental Protection Agency (EPA). By ensuring proper emissions management, these valves not only aid in compliance but also prevent hefty fines and penalties that non-compliant businesses can face. For instance, failure to adhere to EPA regulations can result in penalties exceeding $87,000 per day, emphasizing how vital the adoption of appropriate valves is to avoid such financial repercussions. Moreover, manufacturers are increasingly focusing on eco-friendly valve production methods and materials, such as biodegradable polymers, which significantly contribute to reducing the carbon footprint associated with packaging processes.

Reducing Material Waste Through Reliable Sealing

Reliable sealing solutions present significant long-term cost benefits by minimizing packaging waste. Advanced sealing technologies can lead to reductions in material waste by up to 50%, highlighting their effectiveness in sustainable packaging practices. These reductions not only lower expenses but also improve sustainability credentials, which align with corporate social responsibilities. Embracing such practices enhances brand reputation, as consumers increasingly prefer environmentally responsible companies. Thus, integrating reliable sealing solutions not only optimizes operational efficiency but also contributes to a positive corporate image aligned with global sustainability goals.

Cost-Efficiency and Operational Impact

Minimizing Maintenance Downtime

Minimizing maintenance downtime is critical for ensuring the operational efficiency of packaging operations, and reliable valves play a pivotal role in this aspect. Consistent performance from high-quality valves ensures fewer disruptions, which translates to uninterrupted production and greater cost savings. Research indicates that reducing downtime by 10% can significantly boost profitability due to sustained productivity and reduced repair costs. Expert insights emphasize the importance of regular inspections and preventive maintenance as best practices to maintain valve performance and operational continuity. By focusing on these practices, businesses can enhance their production runs and sustain competitiveness in a rapidly evolving market.

Long-Term ROI Compared to Traditional Valves

Switching from traditional valves to innovative packaging valves has proven to offer a superior long-term return on investment for many businesses. Case studies reveal substantial cost savings and improvements in operational efficiency when companies adopt cutting-edge valve technology. One such study showed a 20% reduction in maintenance costs over five years upon transitioning to modern valves. Furthermore, trends in valve system expenditures demonstrate a shift towards enduring financial advantages, as advanced valves often incorporate improved materials and designs that mitigate frequent replacements and repair expenses. These factors collectively underscore the financial benefits and enhanced competitive position realized by companies embracing innovative valve solutions.

FAQ

What are packaging valves?

Packaging valves are components used in packaging systems that help in maintaining product integrity by controlling air and moisture exchange, preventing spoilage and contamination.

How do packaging valves extend shelf life?

Packaging valves extend shelf life by providing effective sealing that prevents external environmental factors from affecting the product, thereby keeping it fresh longer.

Why is pressure stability important in packaging?

Pressure stability is important because fluctuations can lead to ruptures or leaks, compromising the integrity of the package and the quality of the product.

Are packaging valves environmentally friendly?

Many modern packaging valves are made using eco-friendly materials such as biodegradable polymers, which help in reducing the carbon footprint.

What is the benefit of a Vent PE liner?

A Vent PE liner aids in air exchange and pressure management within sealed containers, contributing to longer shelf life and improved product integrity.

EN

EN

AR

AR

CS

CS

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

ID

ID

VI

VI

TH

TH

TR

TR

MS

MS