Understanding MicroVENT® Acoustic Vent Technology

Core Principles of ePTFE Membrane Design

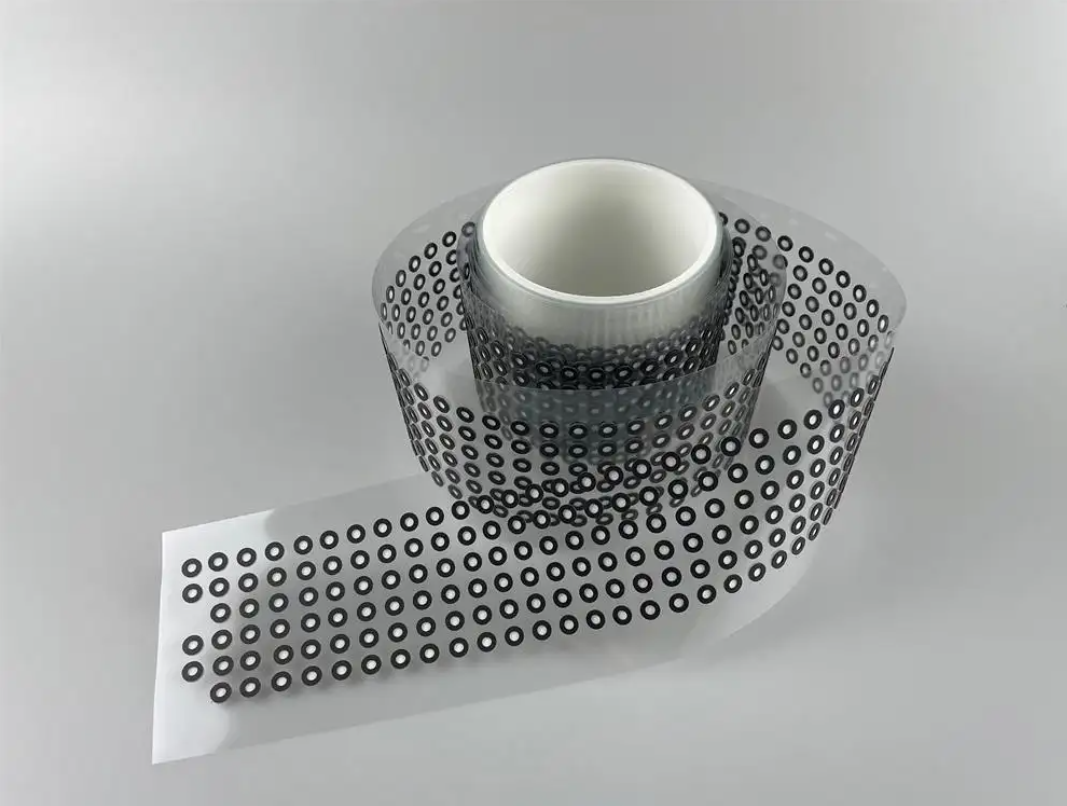

The expanded Polytetrafluoroethylene (ePTFE) membrane is recognized for its remarkable porosity, making it an ideal material for acoustic vent applications. The molecular structure of ePTFE is such that it facilitates the escape of sound waves while effectively blocking water, dust, and other contaminants. This unique design is integral to the technology's ability to balance acoustic transparency with protective functionality. Studies have demonstrated the membrane's effectiveness in reducing noise pollution, illustrating its capability in enhancing the acoustic performance of various devices. Durability and longevity are additional advantages of ePTFE membranes, which retain their structural integrity across diverse environmental conditions, thereby ensuring consistent performance over time. This combination of durability and high acoustic efficiency makes ePTFE membranes a preferred choice in the field of noise reduction technology.

Hydrophobic vs. Oleophobic Vent Configurations

Hydrophobic materials in vent configurations repel water, preventing its entry while allowing sound and air to pass through. Oleophobic vents, on the other hand, are designed to resist oil and other non-water-based contaminants, thus extending their utility in environments with exposure to oils or greasy substances. Acoustic efficiency varies between these two configurations; hydrophobic vents typically excel in devices exposed to wet conditions, maintaining clear acoustic pathways, whereas oleophobic vents are preferred in oily environments. Real-world applications of these vent types include smartphones, automobiles, and medical devices where their specific protective capabilities contribute to product longevity and reliability. Experts suggest choosing between hydrophobic and oleophobic vents based on usage conditions. Devices exposed to harsh weather may benefit from hydrophobic vents, while industrial environments with oil exposure might require oleophobic configurations.

Industrial-Grade Acoustic Vent Solutions

High-pressure Environment Adaptations

In high-pressure environments, engineering processes need to specifically adapt Acoustic Vents to withstand extreme conditions. By leveraging materials science, manufacturers have developed vents that are more robust and reliable than traditional options. We can look at case studies that demonstrate the effectiveness of these adaptations; for instance, companies operating in the petrochemical industry have reportedly seen significant improvements in performance and durability. Statistics also reveal that acoustic vents experience considerably lower failure rates compared to traditional vents, particularly when subjected to high-pressure scenarios. This underscores the innovation and resilience of industrial acoustic vents.

Chemical-resistant Models for Harsh Conditions

Chemical-resistant materials play a pivotal role in manufacturing acoustic vents designed for harsh environments. These materials are crucial in industries like pharmaceuticals, petrochemicals, and waste treatment, where vents must withstand corrosive substances. Examples from these sectors show that chemical-resistant vents maintain operational integrity far more effectively than non-resistant options. Research data corroborate this by indicating higher failure rates for non-resistant vents when exposed to harsh chemicals. Consulting industry experts underscores the importance of selecting appropriate chemical-resistant vents to ensure equipment safety and longevity. These insights are invaluable for businesses looking to protect their investments and maintain efficient operations.

Automotive Acoustic Ventilation Systems

Cabin Noise Reduction Configurations

Automotive designers employ acoustic vents to significantly minimize cabin noise, enhancing the driving experience by reducing unwanted sound levels. These vents integrate advanced materials designed to absorb and dissipate sound waves, making vehicles more comfortable. Technical specifications often include multilayered membranes that provide excellent soundproofing capabilities. Surveys show that consumers appreciate noise reduction features, with a notable increase in satisfaction among recent automotive models. Insights from experts suggest that future innovations might bring even more sophisticated acoustic solutions. For instance, developing new compact designs that can be integrated into smaller vehicular spaces might lead to breakthroughs in vehicular acoustics.

Engine Compartment Thermal-Acoustic Hybrids

The introduction of hybrid vent systems, which blend thermal management with acoustic performance, marks a significant advancement in automotive engineering. These systems are engineered to enhance vehicle performance and passenger comfort by managing heat and controlling noise emanating from the engine compartment. Without effective venting solutions, statistics show that heat-related issues can pose substantial challenges to engine performance. Recognizing this, experts in the field advocate for thermal-acoustic hybrids capable of managing excess heat and noise. As we look to the future, the trajectory of engine acoustic technology is set to address these challenges more efficiently, blending advanced materials and innovative designs to achieve better results.

Electronics-Optimized Acoustic Vents

EMI-shielded micro vents

Electromagnetic interference (EMI) poses a significant challenge to electronic devices by disrupting their functionality. EMI-shielded micro vents are designed to counteract this interference while maintaining acoustics, significantly enhancing the performance of consumer electronics. An example of this is seen in smartphones and tablets, where EMI-shielded vents ensure uninterrupted communication by minimizing distortion. Tech experts underscore the increasing necessity for advanced EMI solutions, especially as the complexity of electronic product designs continues to evolve, integrated with innovative sound systems. Being at the forefront of technology development, companies are investing in this technology to stay competitive and to cater to the demand for high-quality, interference-free electronics.

For detailed specifications and applications of EMI-shielded vents, visit MicroVENT.

Heat-dissipating acoustic designs

Heat dissipation in electronic systems is critical, as excess heat can lead to malfunction and reduced longevity. Heat-dissipating acoustic vents play a dual role by effectively controlling temperature while minimizing sound transmission. These designs are instrumental in devices such as laptops and gaming consoles, where they maintain performance stability under heavy usage conditions. Research highlights that efficient temperature management prolongs device life, reinforcing the need for cutting-edge heat-dissipating solutions. Industry trends forecast advancements in seamless acoustic designs, making future technologies quieter and more resilient to thermal stress.

Explore more about heat-dissipating acoustic designs at MicroVENT.

Specialized Packaging Vent Variants

Pressure-equalizing Acoustic Membranes

Pressure-equalizing acoustic membranes play a crucial role in maintaining product integrity during transport by managing pressure differentials. These membranes are essential for sensitive packaging, particularly in the pharmaceuticals and electronics sectors, where pressure change can compromise product effectiveness or safety. Case studies show successful implementations of this technology, underscoring its effectiveness in maintaining stability. For instance, sensitive electronics and chemical-based pharmaceuticals have benefited significantly. Research further emphasizes the importance of acoustic vent technology; it helps in reducing pressure differentials, ensuring the safety and efficacy of the packaged Products. Looking ahead, experts anticipate that continuous advancements in acoustic solutions will drive the future of packaging technology, providing even more robust solutions to address shifting market demands.

Tamper-evident Venting Solutions

Tamper-evident venting solutions are revolutionizing product security by incorporating features that indicate any unauthorized access. These features are especially beneficial in industries like food, pharmaceuticals, and electronics, where product integrity is paramount. These industries have witnessed significant reductions in potential tampering incidents due to these technologies. Statistical data reveals considerable financial losses due to product tampering, highlighting the need for robust security measures. Vent technology can mitigate these risks by providing enhanced product protection. Packaging experts predict a rise in innovations aimed at strengthening security through vent technology, ensuring that businesses can better protect their products and reassure consumers.

How Does a Vent PE Liner Improve Packaging Performance?

Vent PE liners enhance packaging performance by allowing pressure equalization and protecting against moisture and contaminants, ensuring product safety and longevity. These liners are especially beneficial in the pharmaceutical and electronics industries where maintaining product integrity during transit is crucial. By incorporating vent PE liners, businesses can safeguard against environmental factors that may compromise the product's quality.

FAQ Section

What is ePTFE membrane, and why is it used in acoustic venting?

ePTFE, or expanded Polytetrafluoroethylene, is used in acoustic venting due to its porosity, allowing sound waves to pass through while blocking contaminants like water and dust, offering durability and acoustic efficiency.

How do hydrophobic and oleophobic vents differ?

Hydrophobic vents repel water, allowing sound and air to pass through, while oleophobic vents resist oils and non-water-based contaminants, suitable for devices exposed to greasy or oily substances.

Why are EMI-shielded micro vents important in electronics?

EMI-shielded micro vents are crucial as they mitigate electromagnetic interference, ensuring the functionality and performance of electronic devices by minimizing distortion and enhancing acoustics.

What role do tamper-evident vent solutions play in product security?

Tamper-evident vent solutions enhance product security by indicating unauthorized access, thus minimizing tampering risks, particularly in industries requiring high product integrity like food, pharmaceuticals, and electronics.

EN

EN

AR

AR

CS

CS

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

ID

ID

VI

VI

TH

TH

TR

TR

MS

MS