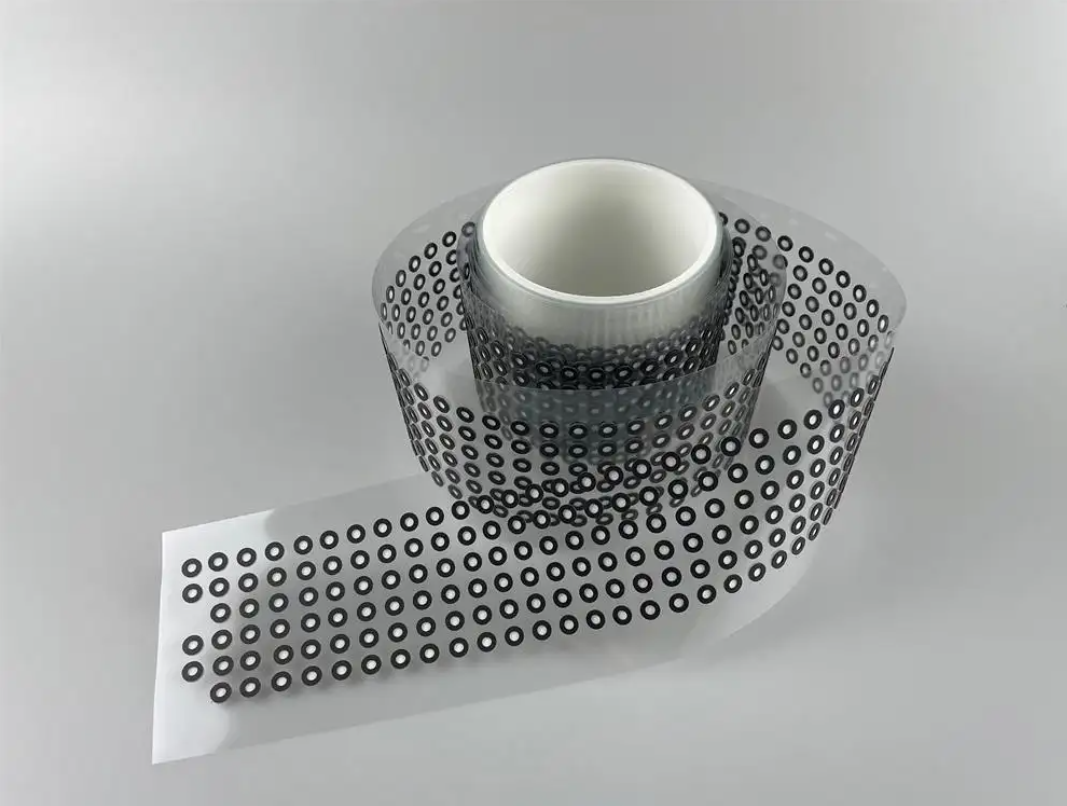

Understanding MicroVent® ePTFE Membrane Technology

Material Composition and Microporous Structure

MicroVent® ePTFE membranes are renowned for their highly distinctive microporous structure, which plays a crucial role in their functionality. At the heart of these membranes is expanded Polytetrafluoroethylene (ePTFE), a fluoropolymer celebrated for its chemical resistance and remarkable breathability. This is achieved by expanding PTFE to yield a labyrinthine network of tiny pores, allowing air and liquid to pass through while blocking larger particulates. Notably, these membranes exhibit selective gas permeability, making them incredibly versatile for applications in industries like medical devices and automotive systems. Studies reveal that ePTFE membranes can be engineered for specific pore sizes, targeting particular contaminants and enhancing filtration efficiency, further confirming their value in diverse sectors.

Expansion Process Creating Nanopore Networks

The expansion process that ePTFE undergoes is fundamental in shaping its advanced properties. This involves heating and stretching the polymer, resulting in a complex network of nanopores that drastically improve its durability and flexibility. This technique allows for precise control over pore sizes, yielding customized solutions tailored to specific use cases. Leading manufacturers highlight this adaptability, noting its capability to withstand varying pressure and temperature conditions. The durability and flexibility derived from the expansion process make ePTFE membranes suitable for a wide range of industrial applications, underscoring their effectiveness in challenging environments.

For more detailed information on the specific applications and versatility of MicroVent® ePTFE membranes, you can visit the product page of MicroVent ePTFE Membrane.

Core Functional Properties of ePTFE Membranes

Selective Gas Permeability & Contaminant Blocking

ePTFE membranes are renowned for their unparalleled selective gas permeability, which allows certain gases to pass through while effectively blocking harmful contaminants. This core functional property is vital for industries where the purity of air and accurate pressure regulation are paramount. Laboratory tests affirm that these membranes can filter out particulates down to the sub-micron level, proving their effectiveness even in polluted environments where air quality control is critical. The reliability of ePTFE membranes in facilitating efficient gas exchange has been documented through various quantitative measures, underscoring their indispensability in sensitive applications.

Chemical Resistance Across Harsh Environments

The exceptional chemical resistance of ePTFE membranes is a key attribute that enables their use in corrosive environments typical to many industrial settings. They're particularly suited for industries such as chemical processing, mining, and pharmaceuticals, where stability against aggressive chemicals is crucial. Research has shown that ePTFE membranes can withstand contact with acids, bases, and solvents without degrading, which demonstrates their remarkable durability. These unique properties have been recognized by various institutions, making ePTFE membranes a preferred choice in industrial protocols for safety and consistency.

Thermal Stability from -200°C to 260°C

ePTFE membranes exhibit outstanding thermal stability, allowing them to maintain integrity across a wide temperature range from -200°C to 260°C. This makes them ideal for deployment in extreme thermal conditions, such as cryogenics and high-heat environments. Industrial tests have consistently shown that ePTFE membranes can sustain their functional properties under significant thermal stress, without any compromise in performance. Documented evidence of their thermal stability highlights that there is no loss of permeability or structural failure, ensuring their continued effectiveness and reliability in demanding conditions.

Key Industrial Applications of ePTFE Membrane Solutions

Automotive Pressure Equalization Systems

ePTFE membranes are indispensable in automotive pressure equalization systems, allowing pressure balance while keeping moisture out. These membranes are designed to maintain their functionality amidst temperature fluctuations, thereby enhancing the reliability of engine and transmission components. Automotive manufacturers have reported significant improvements in system reliability when integrating ePTFE membranes in both electrical and mechanical systems. This not only helps in maintaining optimal performance but also prolongs the lifespan of the components by preventing moisture-related corrosion and wear.

Electronics Enclosure Moisture Control

In electronics, ePTFE membranes are critical for moisture control within enclosures, safeguarding devices from condensation and prolonging their operational life. The permeability of these membranes allows for effective heat dissipation, which is crucial in preventing the ingress of damaging moisture into sensitive electronic components. Studies highlight a marked reduction in failure rates of moisture-sensitive electronics protected by ePTFE membranes, underscoring their efficacy. By keeping electronics dry and functional, these membranes contribute to the reliability and longevity of various electronic devices.

Medical Device Sterile Ventilation

ePTFE membranes play a vital role in medical device applications, especially in maintaining sterile ventilation systems. They excel in filtering out pathogens while ensuring the necessary airflow required for maintaining sterility, which is critical in medical environments. Clinical use cases provide evidence of reduced infection rates where ePTFE membranes are utilized, emphasizing their effectiveness in medical applications. This filtration capability ensures that medical devices operate safely and hygienically, protecting patients and healthcare professionals alike.

Battery Safety Venting Mechanisms

The application of ePTFE membranes in battery safety venting systems is crucial for preventing gas build-up and ensuring safety. Their inherent thermal stability and chemical resistance make them ideal for use in lithium-ion battery designs, where fluctuations can pose risks. Reports from battery manufacturers confirm that ePTFE membranes significantly lower failure incidents, thus enhancing the safety and reliability of battery designs. These membranes allow hazardous gases to escape safely without letting moisture or contaminants enter the battery systems.

Industrial Filtration Systems

In the industrial domain, ePTFE membranes serve as advanced solutions for air and liquid filtration systems across many sectors. Their high dirt-holding capacity and efficiency in cleaning make them a preferred choice for complex filtration needs within various industries. Independent reviews consistently spotlight ePTFE membranes' superior filtration properties compared to traditional materials, further affirming their status as a premium choice. This reliability and efficiency in filtration enhance operational outcomes and promote cleaner industrial processes, benefiting the environment and human health alike.

Performance Advantages Over Traditional Materials

Superior Lifespan vs Rubber/Plastic Vents

ePTFE membranes significantly outperform rubber and plastic vents in terms of lifespan, often lasting many years longer. This remarkable durability translates to reduced maintenance costs and a decrease in replacement frequency, leading to lower overall lifecycle expenses. Industry testimonials have consistently recognized the extraordinary durability of ePTFE membranes across various applications. For instance, in automotive systems, these membranes have demonstrated their robustness under extreme conditions, contributing to improved reliability and efficiency. By investing in ePTFE membrane solutions, businesses can ensure long-term reliability and cost savings.

Passive Operation Without Energy Input

ePTFE membranes operate passively, requiring no external energy input, unlike mechanical venting systems. This feature promotes energy efficiency and renders them an environmentally friendly choice for various applications. The inherent ability to function without power helps conserve energy in systems where efficiency is vital, such as electronics and medical devices. Substantial reports have highlighted substantial energy savings in systems utilizing ePTFE membranes, further underscoring their contribution to sustainable practices and reduced operational costs.

IP67/IP68 Environmental Protection

With IP67/IP68 ratings, ePTFE membranes provide robust protection against water and dust ingress, enhancing their suitability for demanding environments. This level of environmental protection makes them ideal for outdoor and industrial applications where exposure to harsh elements is a concern. Comprehensive evaluations by major environmental testing agencies underscore the reliability of these membranes under adverse conditions, validating their efficacy in safeguarding sensitive equipment. ePTFE membranes thus emerge as a preferred choice for businesses seeking resilient solutions for challenging operational environments. For example, ePTFE's effectiveness against water ingress is particularly beneficial in electronics enclosure protection, ensuring device longevity and reduced failure rates.

Products utilizing such technology can be explored through choices like MicroVENT® Automotive Vents, which integrate ePTFE membranes for optimized performance.

Implementation Considerations for Membrane Integration

Pore Size Customization for Application Demands

Customization of pore sizes is vital for meeting specific application requirements, enabling precise filtration and gas exchange. Manufacturers offer a variety of pore sizes, ranging from microscale to nanoscale, accommodating diverse needs across industries. For instance, in medical devices, precise pore sizes ensure effective filtration of particles, enhancing both the safety and efficiency of the devices. Evidence from product lines indicates that these tailored solutions lead to improved performance, especially in complex environments. The flexibility to select the appropriate pore size allows industries to optimize their processes and ensure the efficacy of their operations while meeting distinct demands.

Adhesive Bonding & Sealing Methodologies

The performance of ePTFE membranes heavily depends on the effectiveness of adhesive bonding and sealing techniques employed during installation. Proper methodologies can ensure durability and optimal function, preventing leaks and ensuring longevity in practical applications. Understanding different bonding methodologies enhances membrane integrity, preventing environmental exposure from degrading membrane performance. Successful case studies highlight how meticulous sealing can significantly improve overall system effectiveness, maintaining the desired conditions within enclosures. Therefore, selecting the right adhesive and sealing approach is crucial for achieving robust and reliable system function.

FDA Compliance for Medical Use Cases

Ensuring FDA compliance is crucial when utilizing ePTFE membranes in medical applications, as adherence to the standards guarantees both safety and efficacy. Manufacturers must operate under stringent regulations to ensure that these membranes meet the necessary legal requirements for medical device use. Compliance documents from regulatory bodies underline the importance of conforming to guidelines to foster trust and reliability in medical devices. In applications such as sterile ventilation, appropriately certified ePTFE membranes provide dependable solutions that adhere to health and safety standards. Therefore, prioritizing FDA compliance is essential when integrating these membranes into medical devices for assured protection and performance.

FAQ

What are MicroVent® ePTFE membranes made of?

They are made of expanded Polytetrafluoroethylene (ePTFE), a fluoropolymer known for its chemical resistance and breathability.

How do ePTFE membranes benefit medical devices?

They provide sterile ventilation by filtering pathogens while ensuring airflow, critical for maintaining sterility in medical applications.

Can the pore size of ePTFE membranes be customized?

Yes, manufacturers offer customization of pore sizes to meet specific filtration and gas exchange needs across various industries.

What industries benefit from the use of ePTFE membranes?

Industries such as automotive, electronics, medical, battery systems, and industrial filtration benefit from their use.

EN

EN

AR

AR

CS

CS

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

ID

ID

VI

VI

TH

TH

TR

TR

MS

MS