Versatile Application Solutions

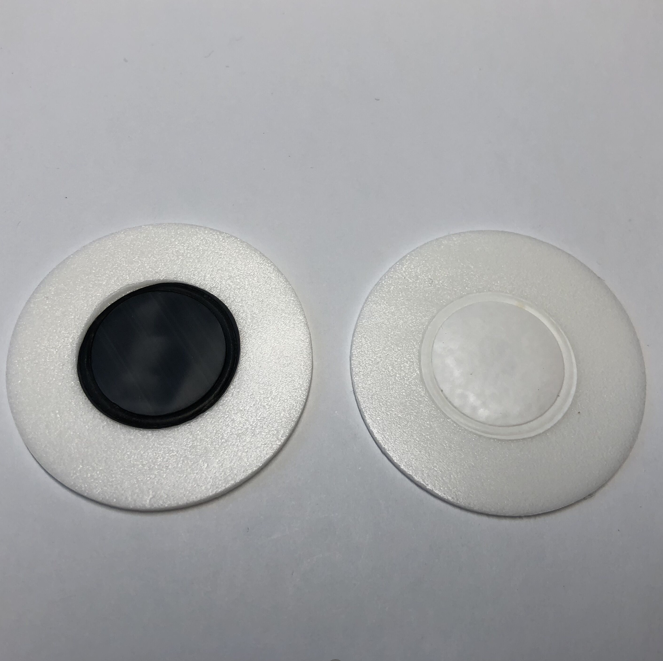

The waterproof foam liner offers unmatched versatility across diverse applications, from residential basement waterproofing to industrial equipment protection and marine environments. Its adaptable characteristics accommodate various installation methods, substrate types, and environmental conditions, making it the preferred choice for contractors and engineers seeking reliable moisture protection solutions. The material conforms to irregular surfaces and complex geometries, providing effective sealing around pipes, conduits, and structural elements that challenge rigid waterproofing systems. Waterproof foam liner installations adapt to both horizontal and vertical applications, maintaining protective effectiveness regardless of orientation or surface angle. The lightweight composition enables installation in weight-sensitive applications where traditional materials would exceed load limitations. Compatibility with various adhesives, mechanical fasteners, and sealing systems allows integration into existing waterproofing assemblies and retrofit applications. The waterproof foam liner performs effectively in underground applications, roofing systems, vehicle manufacturing, cold storage facilities, and marine environments where moisture control is critical. Temperature resistance characteristics accommodate applications ranging from refrigerated storage to heated industrial processes, ensuring consistent performance across extreme temperature ranges. The material's flexibility allows installation over moving joints and expansion areas without compromising seal integrity, making it ideal for structures subject to thermal movement or settling. Customization options include various thicknesses, surface textures, and dimensional configurations that optimize performance for specific application requirements. The waterproof foam liner integrates seamlessly with other building materials and waterproofing components, creating comprehensive moisture protection systems that address complex environmental challenges. Installation techniques accommodate both new construction and retrofit applications, providing cost-effective solutions for upgrading existing moisture protection systems. The material's chemical inertness makes it suitable for contact with various substances in industrial processing, food handling, and pharmaceutical applications where contamination prevention is essential.