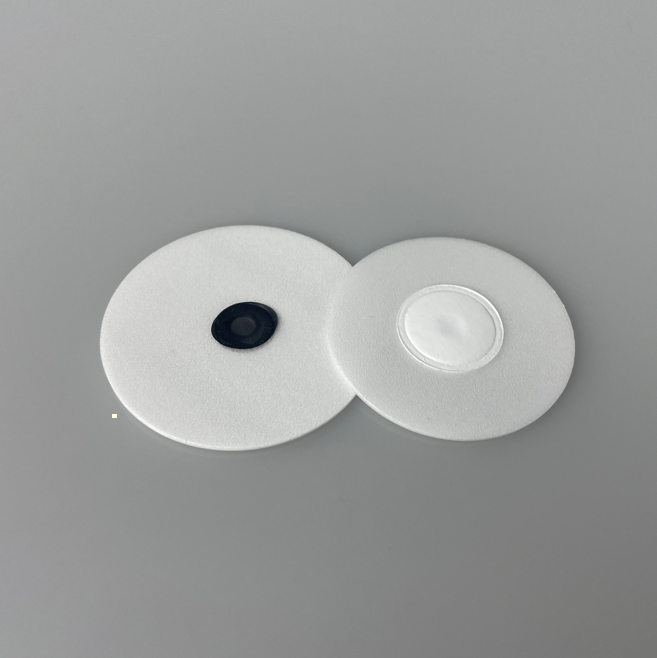

gore pe liner

The gore pe liner represents a cutting-edge solution in waterproofing and environmental protection applications, combining advanced polymer technology with exceptional durability. This innovative liner system utilizes high-density polyethylene material enhanced with specialized additives to create an impermeable barrier that withstands harsh environmental conditions. The gore pe liner serves as a critical component in various industries including waste management, mining operations, water treatment facilities, and construction projects where reliable containment is essential. Its primary function involves preventing liquid penetration and contamination, making it an indispensable tool for environmental safety and regulatory compliance. The technological foundation of the gore pe liner incorporates advanced extrusion processes that create uniform thickness and consistent material properties throughout the entire liner surface. This manufacturing approach ensures optimal performance characteristics including chemical resistance, UV stability, and mechanical strength. The liner's molecular structure provides exceptional flexibility while maintaining structural integrity under extreme temperature variations, making it suitable for both indoor and outdoor applications. Installation versatility represents another key aspect of the gore pe liner system, as it can be deployed in various configurations including horizontal installations, vertical applications, and complex geometric shapes. The material's weldability allows for seamless connections between liner sections, creating continuous barriers without weak points that could compromise containment effectiveness. Environmental sustainability considerations have been integrated into the gore pe liner design, with recyclable materials and manufacturing processes that minimize ecological impact. The liner's longevity reduces replacement frequency, contributing to overall sustainability goals while providing cost-effective long-term solutions. Quality control measures ensure that each gore pe liner meets stringent industry standards and performance specifications, providing customers with reliable protection for their critical containment applications.