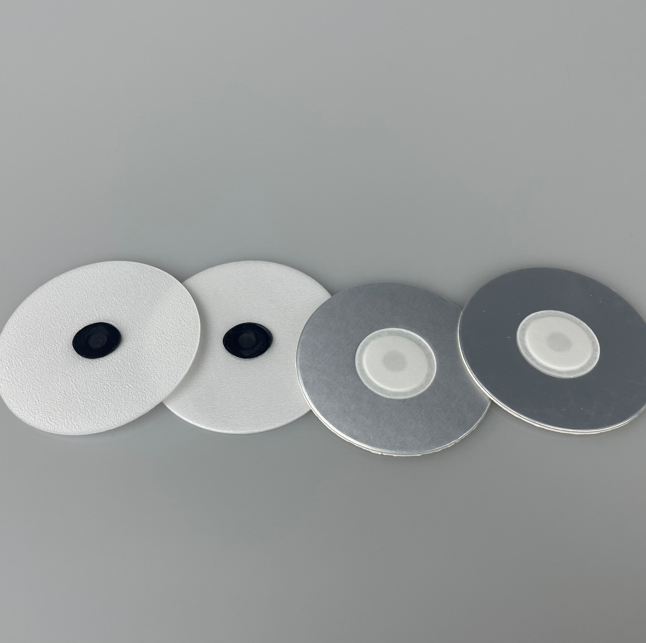

chemical cap

The chemical cap represents a revolutionary advancement in industrial closure technology, designed specifically to provide superior protection for chemical containers and processing equipment. This innovative sealing solution incorporates advanced materials engineering and precision manufacturing techniques to deliver unmatched performance in demanding chemical environments. The chemical cap serves as a critical barrier between hazardous substances and the external environment, ensuring both safety and product integrity throughout storage and transportation processes. Modern chemical cap designs utilize specialized polymer compounds and metal alloys that resist corrosion, chemical degradation, and extreme temperature fluctuations. The primary function of a chemical cap extends beyond simple containment, as it actively prevents contamination, maintains product purity, and reduces the risk of dangerous chemical reactions. These caps feature sophisticated sealing mechanisms that create airtight barriers, preventing vapor escape and maintaining optimal internal pressure conditions. The technological framework of each chemical cap includes multiple layers of protection, incorporating gaskets, threads, and locking mechanisms that work together to ensure complete closure integrity. Manufacturing processes for chemical cap production involve rigorous quality control measures, including pressure testing, chemical resistance evaluation, and durability assessments. The versatility of chemical cap applications spans across pharmaceutical manufacturing, petrochemical processing, laboratory research, and industrial chemical production facilities. Each chemical cap undergoes extensive testing to meet international safety standards and regulatory requirements, ensuring compliance with industry-specific protocols. The design philosophy behind every chemical cap emphasizes both functionality and user safety, incorporating features that facilitate easy installation while maintaining maximum security. Advanced chemical cap models include built-in pressure relief systems and tamper-evident features that provide additional layers of protection and monitoring capabilities.