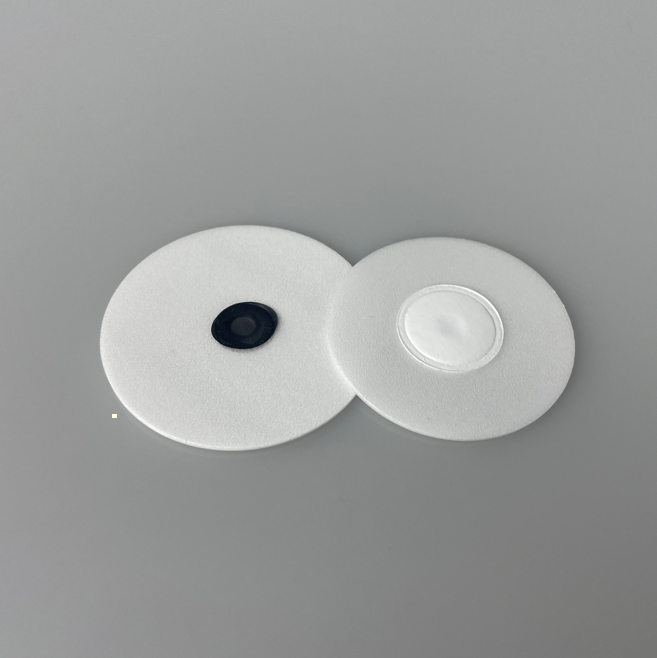

breathable packaging gasket

The breathable packaging gasket represents a revolutionary advancement in modern packaging technology, designed to address the critical balance between product protection and environmental interaction. This innovative sealing solution incorporates specialized materials and engineering techniques that allow controlled air exchange while maintaining essential barrier properties. Unlike traditional solid gaskets, the breathable packaging gasket features microscopic pores or permeable membranes that enable selective gas transmission, making it ideal for applications where complete air-tight sealing would be detrimental to product quality or safety. The primary function of a breathable packaging gasket centers on providing selective permeability that allows moisture vapor and specific gases to pass through while blocking contaminants, dust, and liquid penetration. This controlled breathing capability prevents pressure buildup inside packages, reduces condensation formation, and maintains optimal internal atmospheric conditions for sensitive products. The technological foundation of the breathable packaging gasket relies on advanced materials science, incorporating polymeric membranes, microporous films, or specially treated fabrics that exhibit directional permeability characteristics. These materials undergo precise manufacturing processes to achieve consistent pore structures and predetermined transmission rates. Key technological features include hydrostatic pressure resistance, temperature stability, chemical compatibility, and long-term performance reliability. The gasket maintains its breathable properties across wide temperature ranges while resisting degradation from environmental factors. Applications for breathable packaging gasket technology span multiple industries, including food packaging, pharmaceutical containers, electronic device enclosures, automotive components, and industrial equipment housings. In food applications, these gaskets prevent spoilage by allowing natural respiration while blocking external contaminants. Pharmaceutical packages benefit from controlled moisture management that maintains drug stability without compromising sterility. Electronic applications utilize breathable gaskets to prevent condensation damage while maintaining environmental sealing standards. The versatility of breathable packaging gasket design allows customization for specific permeability requirements, chemical resistance needs, and dimensional specifications.