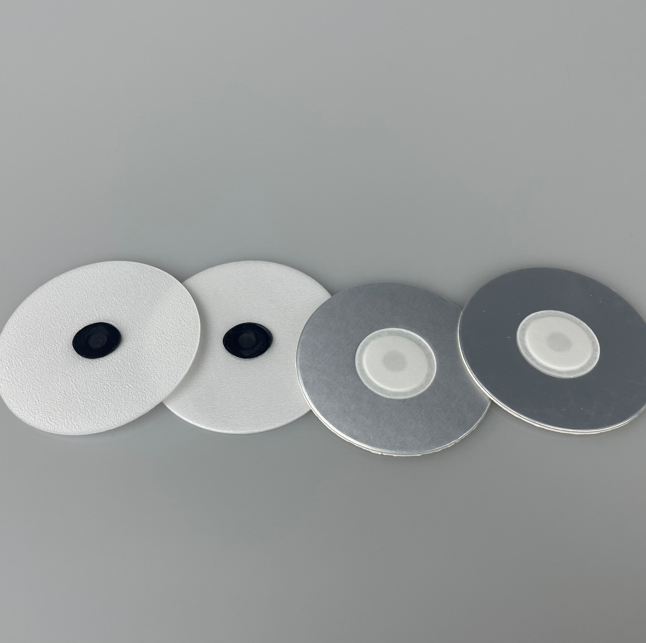

fertilizer cap

The fertilizer cap represents a revolutionary advancement in agricultural packaging technology, designed to enhance the storage, dispensing, and application of liquid and granular fertilizers. This specialized closure system serves as the critical interface between fertilizer containers and agricultural equipment, ensuring optimal product preservation and controlled distribution. Modern fertilizer caps incorporate sophisticated engineering principles to address the unique challenges posed by chemical fertilizers, including corrosion resistance, precise flow control, and contamination prevention. The primary functions of fertilizer caps encompass sealing integrity, chemical compatibility, and user-friendly operation. These caps maintain airtight seals to prevent moisture ingress, oxidation, and volatile compound escape, thereby preserving fertilizer potency and extending shelf life. The technological features integrated into contemporary fertilizer cap designs include multi-layered polymer construction, chemical-resistant gaskets, and precision-molded threading systems. Advanced models incorporate tamper-evident mechanisms, child-resistant features, and compatibility indicators for various fertilizer formulations. The cap's internal components often feature specialized valve systems that regulate flow rates, preventing waste and ensuring accurate application rates. Applications of fertilizer caps span across diverse agricultural sectors, from small-scale farming operations to large commercial agricultural enterprises. Professional farmers utilize these caps for connecting fertilizer containers to irrigation systems, spray equipment, and direct application machinery. The agricultural industry relies heavily on fertilizer cap technology for maintaining product quality during transportation, storage, and field application. Greenhouse operations particularly benefit from precise dispensing capabilities, while organic farming operations appreciate the contamination prevention features. The versatility of fertilizer cap applications extends to liquid fertilizer concentrates, water-soluble granules, and specialty nutrient solutions, making them indispensable components in modern agricultural practices.