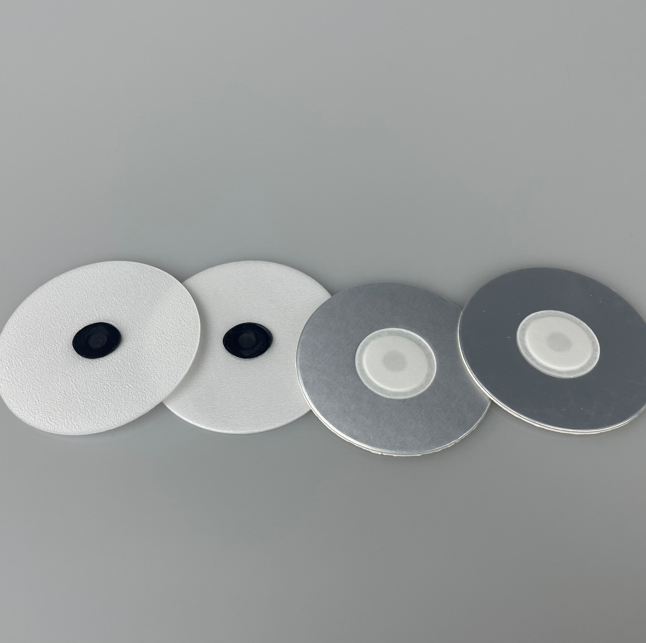

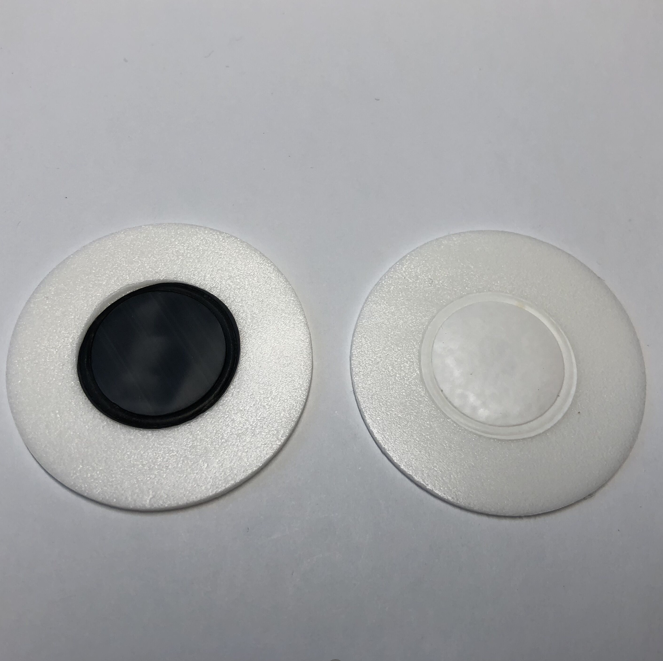

breathable pe seal

The breathable pe seal represents a revolutionary advancement in packaging technology, combining the protective qualities of traditional sealing materials with enhanced air permeability features. This innovative sealing solution utilizes specialized polyethylene materials engineered with microscopic pores that allow controlled gas exchange while maintaining barrier properties against moisture, dust, and contaminants. The breathable pe seal technology addresses critical challenges in various industries where products require protection without complete atmospheric isolation. The main functions of this sealing system include moisture regulation, pressure equalization, and contamination prevention while preserving product integrity. The technological foundation relies on advanced polymer engineering that creates a selective barrier membrane. This membrane permits the passage of specific gases like oxygen and carbon dioxide while blocking larger particles and liquid moisture. The manufacturing process involves precision extrusion techniques that create uniform pore distribution throughout the material structure. These pores are calibrated to specific sizes, ensuring optimal breathability rates for different applications. The breathable pe seal demonstrates exceptional durability under various environmental conditions, maintaining its sealing properties across temperature ranges from -40°C to 80°C. The material exhibits excellent chemical resistance against common solvents, oils, and cleaning agents. Applications span numerous industries including food packaging, pharmaceutical storage, electronic component protection, and agricultural product containment. In food packaging, the breathable pe seal extends shelf life by controlling oxygen levels and preventing anaerobic bacterial growth. For pharmaceutical applications, it maintains drug stability by regulating moisture content while protecting against contamination. Electronic manufacturers utilize these seals to prevent condensation damage while allowing pressure equalization during altitude changes. Agricultural applications benefit from controlled ripening processes and reduced spoilage rates. The versatility of breathable pe seal technology makes it suitable for both consumer and industrial applications, offering customizable permeability rates based on specific product requirements.