Versatile Applications and Installation Flexibility

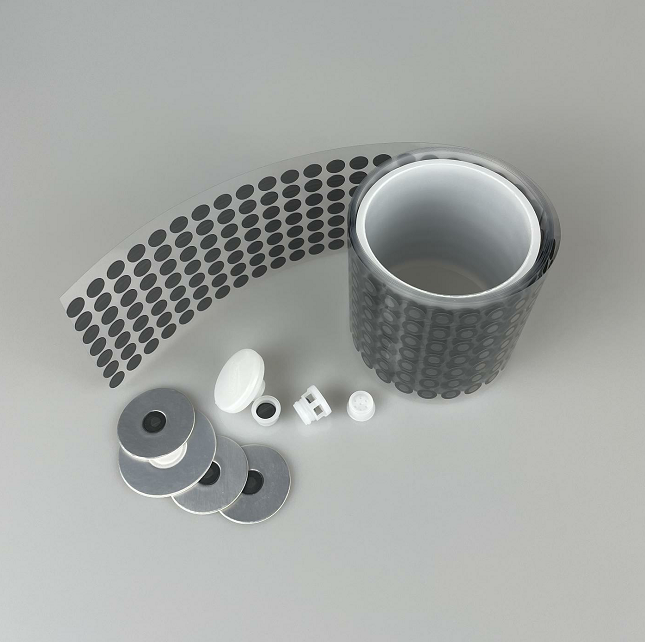

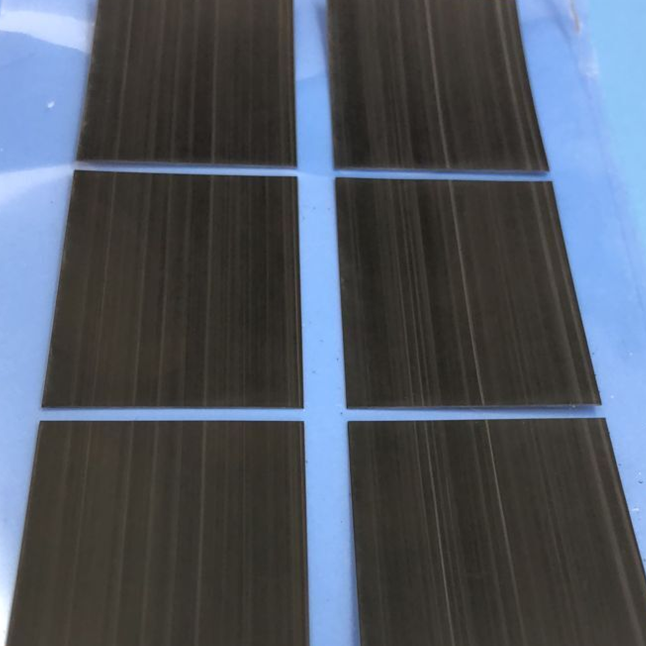

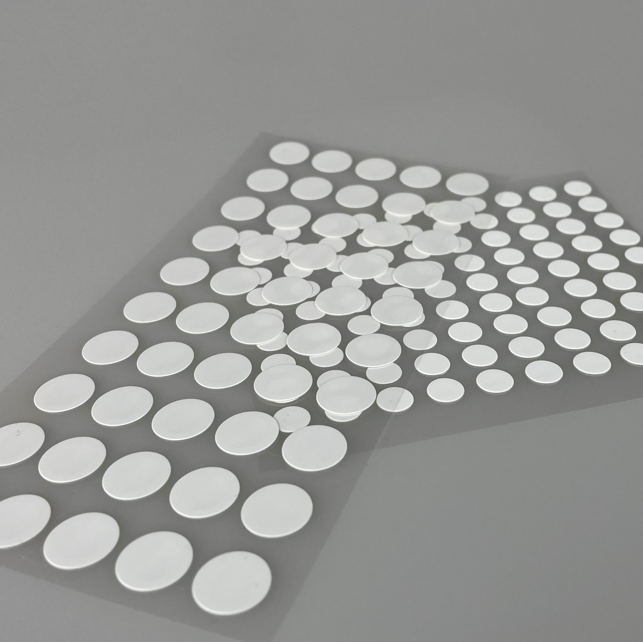

The lighting eptfe membrane demonstrates remarkable versatility across diverse lighting applications, offering unparalleled installation flexibility that adapts to virtually any lighting design requirement. This adaptability makes the lighting eptfe membrane an ideal solution for manufacturers, installers, and end-users seeking reliable protection across multiple lighting categories. Automotive applications benefit significantly from the membrane's ability to protect headlights, taillights, and interior lighting systems from moisture, debris, and thermal stress while maintaining optimal light output for safety-critical visibility functions. The lighting eptfe membrane's conformability allows it to integrate seamlessly with complex curved surfaces and intricate lighting assemblies common in modern vehicle designs. Architectural lighting installations utilize the membrane's weather resistance and aesthetic properties to protect outdoor fixtures, landscape lighting, and building accent systems while preserving their intended visual impact. Marine lighting applications particularly benefit from the membrane's salt water resistance and pressure equalization properties, making it essential for navigation lights, deck illumination, and underwater lighting systems. Industrial environments demand robust protection, and the lighting eptfe membrane delivers exceptional performance in chemical processing facilities, manufacturing plants, and hazardous locations where traditional materials fail. The membrane's explosion-proof compatibility enables its use in classified environments while maintaining lighting functionality and safety standards. Residential applications include outdoor security lighting, garden illumination, and architectural accent systems where long-term reliability and low maintenance are priorities. The lighting eptfe membrane's biocompatibility makes it suitable for indoor air quality sensitive environments, including hospitals, schools, and residential spaces. Installation processes are simplified by the membrane's flexibility and compatibility with standard mounting hardware, reducing installation time and complexity. Custom sizing and shaping capabilities allow the lighting eptfe membrane to accommodate unique fixture designs and retrofit applications without compromising protective performance. The membrane's compatibility with various sealing methods, including mechanical fastening, adhesive bonding, and thermal welding, provides installation flexibility for different manufacturing processes. Quality assurance protocols ensure consistent performance across all application categories, providing reliable protection standards regardless of the specific use case or environmental conditions.