breathable acoustic sticker

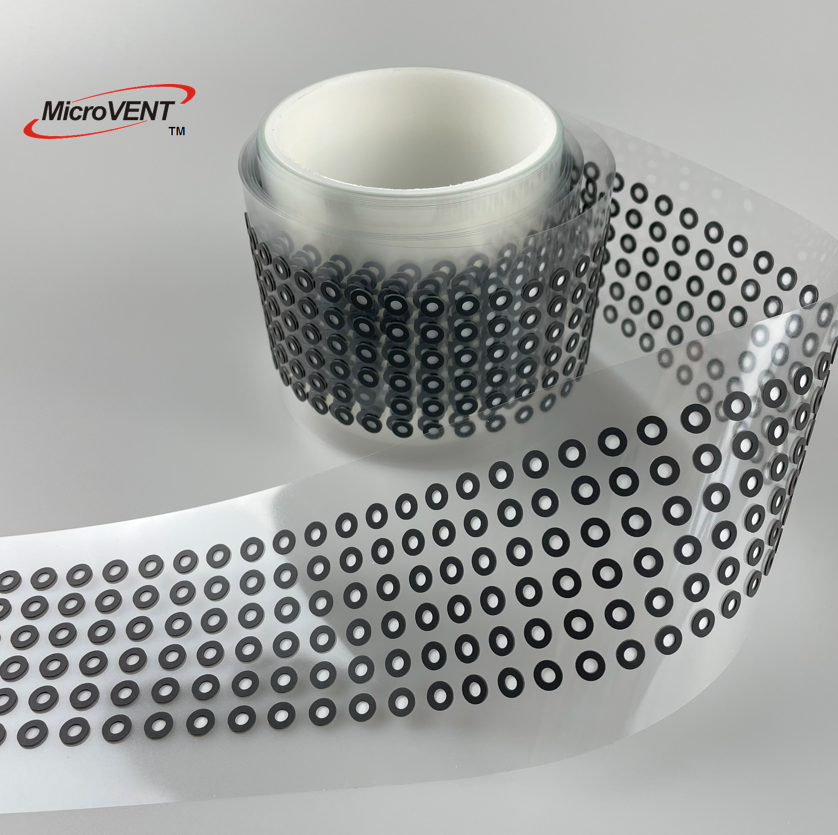

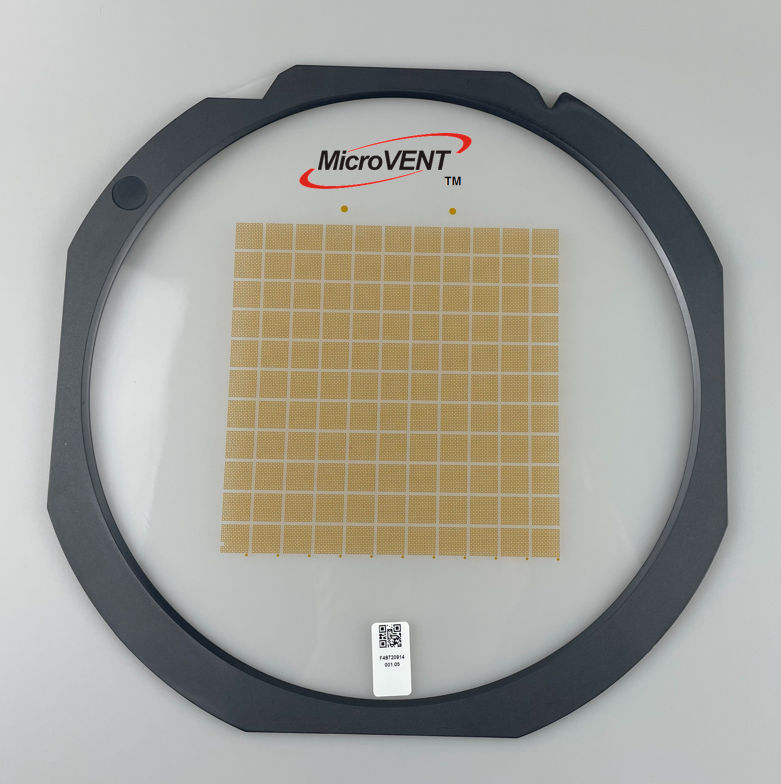

The breathable acoustic sticker represents a revolutionary advancement in sound management technology, combining superior noise control capabilities with essential ventilation properties. This innovative solution addresses the common challenge faced by traditional soundproofing materials that often compromise air circulation while managing acoustic performance. The breathable acoustic sticker utilizes cutting-edge microporous technology that allows air molecules to pass through while effectively blocking unwanted sound waves. This dual functionality makes it an ideal choice for environments where both acoustic comfort and air quality are paramount concerns. The product features a specialized polymer matrix embedded with microscopic channels that facilitate controlled airflow without sacrificing sound absorption efficiency. These channels are engineered at the molecular level to maintain optimal acoustic properties while ensuring consistent breathability across various temperature and humidity conditions. The sticker format provides unprecedented installation convenience, eliminating the need for complex mounting systems or professional installation services. Users can simply peel and apply the material to target surfaces, making it accessible for both residential and commercial applications. The adhesive backing utilizes advanced bonding agents that ensure long-term adherence without damaging underlying surfaces upon removal. Key technological features include multi-frequency sound absorption capabilities, moisture-resistant construction, and flame-retardant properties that meet international safety standards. The material maintains its acoustic performance across a wide range of environmental conditions, from humid bathrooms to temperature-controlled office spaces. Applications span numerous industries and settings, including residential homes, commercial offices, healthcare facilities, educational institutions, recording studios, and automotive interiors. The breathable acoustic sticker proves particularly valuable in spaces requiring both noise reduction and adequate ventilation, such as server rooms, mechanical equipment areas, and HVAC system installations where traditional soundproofing methods would impede necessary airflow patterns.