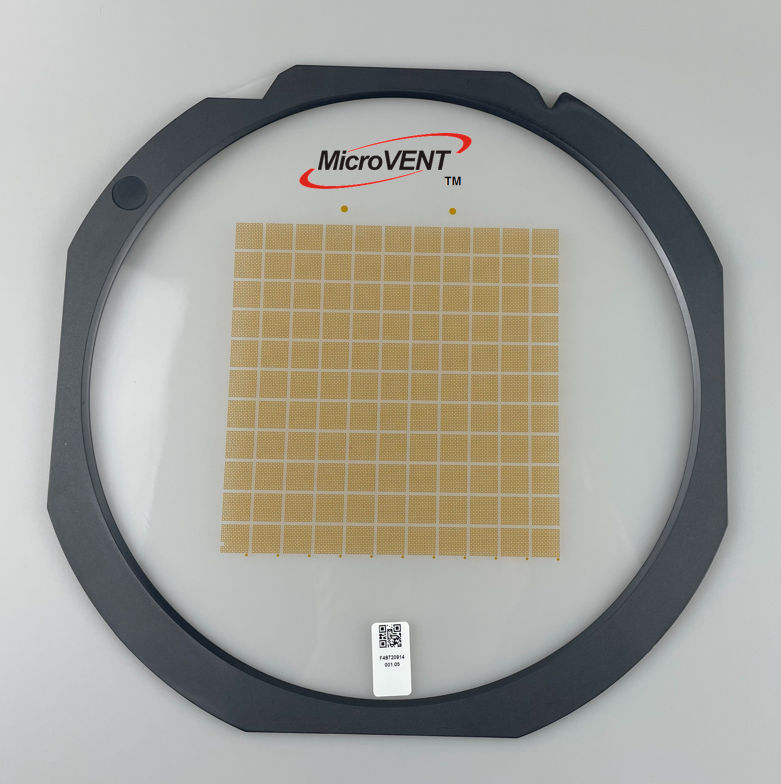

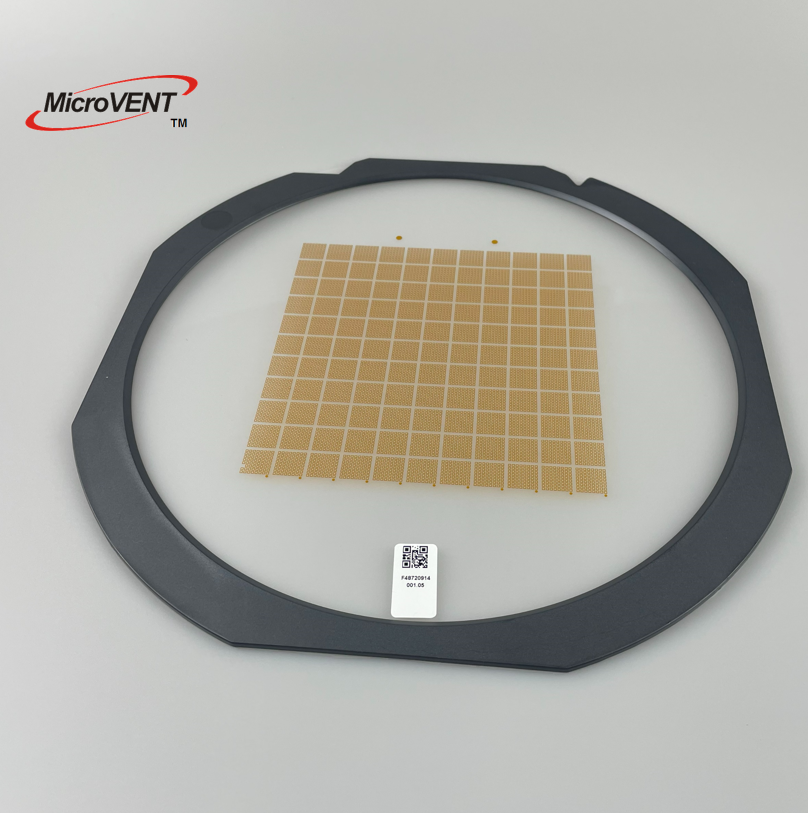

Versatile Installation Flexibility and Surface Compatibility

The acoustic eptfe sticker offers unmatched installation versatility that accommodates diverse surface materials, complex geometries, and challenging application requirements across multiple industries and environments. This flexibility begins with its advanced adhesive system, specifically engineered to bond securely to metals, plastics, composites, glass, ceramics, and painted surfaces without requiring surface primers, mechanical fasteners, or specialized preparation procedures. The conformable nature of the acoustic eptfe sticker allows installation on curved surfaces, irregular contours, and three-dimensional shapes that would be impossible to treat with rigid acoustic panels or traditional sound-dampening materials. Installation teams appreciate the product's ability to stretch and conform to surface variations while maintaining uniform thickness and consistent acoustic properties throughout the applied area. The pressure-sensitive adhesive activates immediately upon contact, providing instant bond formation that eliminates waiting periods and allows immediate return to service. This installation efficiency becomes particularly valuable during maintenance shutdowns, retrofit projects, and emergency acoustic treatments where time constraints are critical. The acoustic eptfe sticker can be die-cut to precise shapes and dimensions, enabling custom solutions for equipment housings, access panels, and irregular spaces where standard acoustic materials would require extensive modification. Its thin profile adds minimal thickness to existing assemblies, making it ideal for space-constrained applications where clearances are tight. The product's removability feature allows temporary installations, equipment modifications, and future upgrades without damaging underlying surfaces or leaving adhesive residue. Field installation requires no special tools, heating equipment, or curing time, allowing maintenance personnel to complete acoustic treatments using basic hand tools and minimal training. The acoustic eptfe sticker maintains adhesive performance on surfaces with slight contamination, oil films, or surface oxidation that would prevent other adhesive systems from bonding effectively. This tolerance for real-world surface conditions significantly reduces preparation time and installation complexity in industrial environments where perfectly clean surfaces are difficult to achieve and maintain.