Versatile Integration and Customization Capabilities

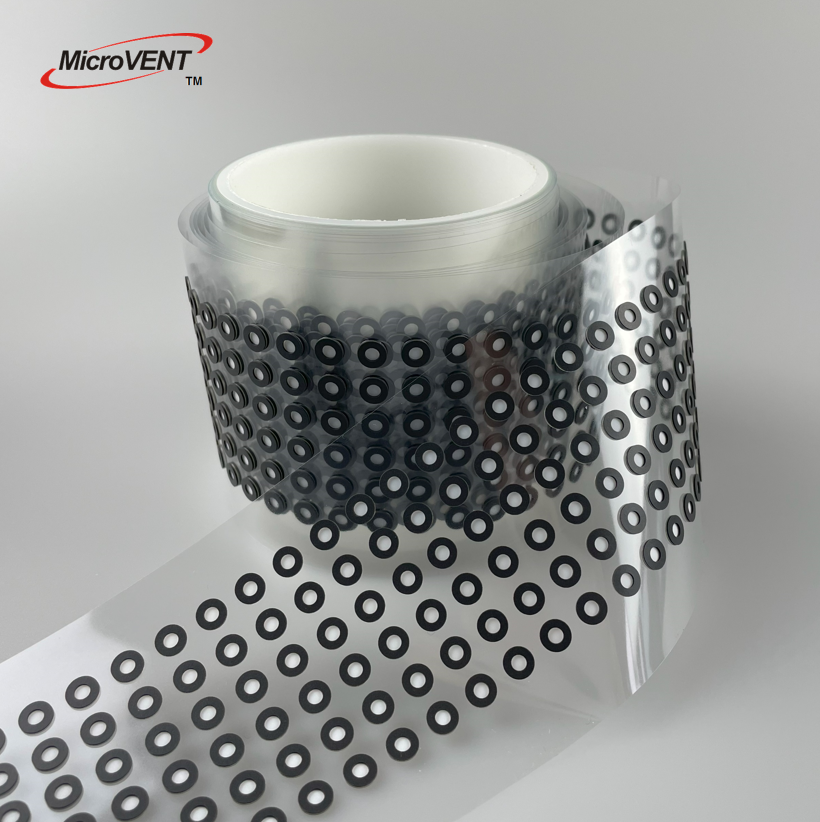

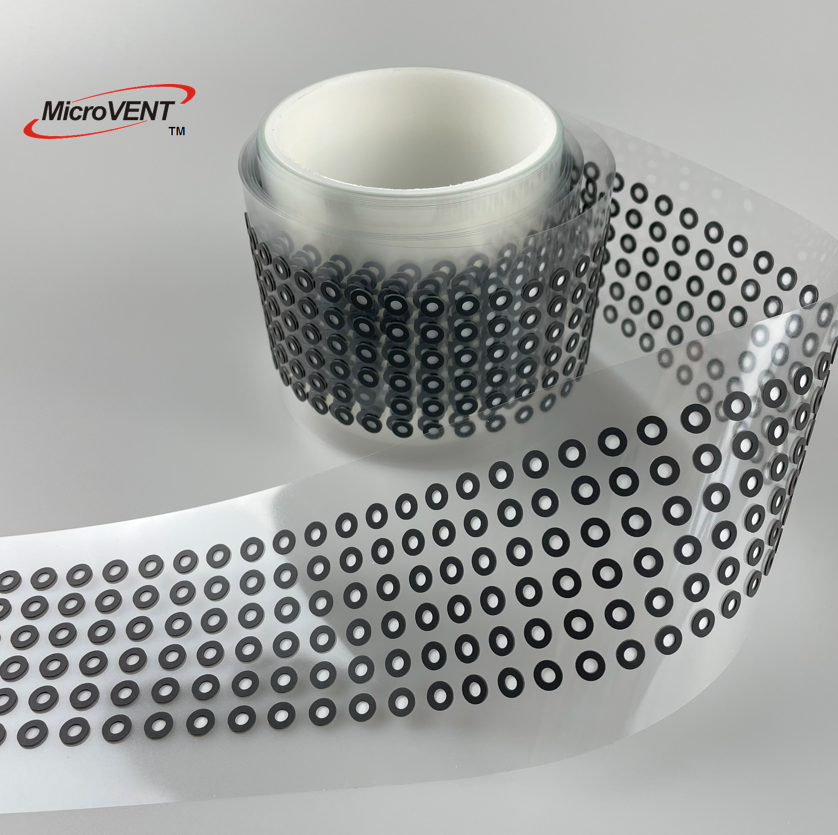

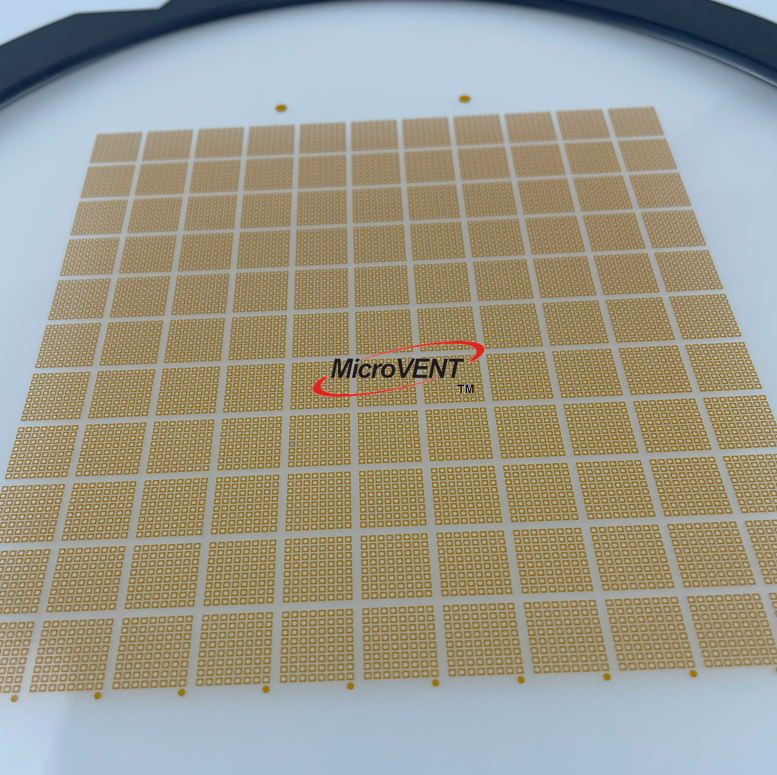

The acoustic eptfe membrane offers exceptional design flexibility that enables seamless integration into diverse acoustic systems while meeting specific performance requirements through customizable material properties. Manufacturing processes allow precise control over membrane thickness, pore size distribution, and surface characteristics to optimize acoustic performance for particular applications, from microscale electronic devices to large industrial systems. The material's inherent flexibility and conformability facilitate installation on curved surfaces, complex geometries, and tight-tolerance assemblies without compromising acoustic properties or creating installation difficulties. Bonding compatibility extends across multiple adhesive chemistries, mechanical fastening systems, and thermal welding processes, providing designers with numerous integration options to suit specific assembly requirements and manufacturing capabilities. The acoustic eptfe membrane can be supplied in roll goods for continuous processing applications or precision die-cut components for automated assembly operations, supporting both high-volume manufacturing and custom fabrication requirements. Lamination capabilities enable composite construction with other materials to create multi-functional assemblies that combine acoustic control with additional properties such as electromagnetic shielding, thermal insulation, or barrier protection. Surface treatment options modify adhesion characteristics, appearance, or functional properties while maintaining core acoustic performance, enabling aesthetic integration in visible applications or enhanced bonding in structural assemblies. The acoustic eptfe membrane supports various packaging and handling methods that accommodate different manufacturing environments and quality control requirements, from clean room processing to standard industrial assembly operations. Dimensional stability ensures consistent fit and performance across temperature cycling and environmental exposure, eliminating assembly difficulties caused by material shrinkage or expansion. Quality assurance programs provide comprehensive testing and certification documentation that supports regulatory compliance and quality system requirements across industries including automotive, aerospace, medical devices, and industrial equipment. Custom specification development services enable optimization of acoustic eptfe membrane properties for unique applications, drawing on extensive material science expertise and acoustic engineering capabilities to deliver solutions that exceed standard product performance. Technical support services assist with material selection, system design optimization, and integration troubleshooting to ensure successful implementation and maximum performance benefits from acoustic eptfe membrane installations in both new product development and retrofit applications.