Versatile Installation and Customization Options

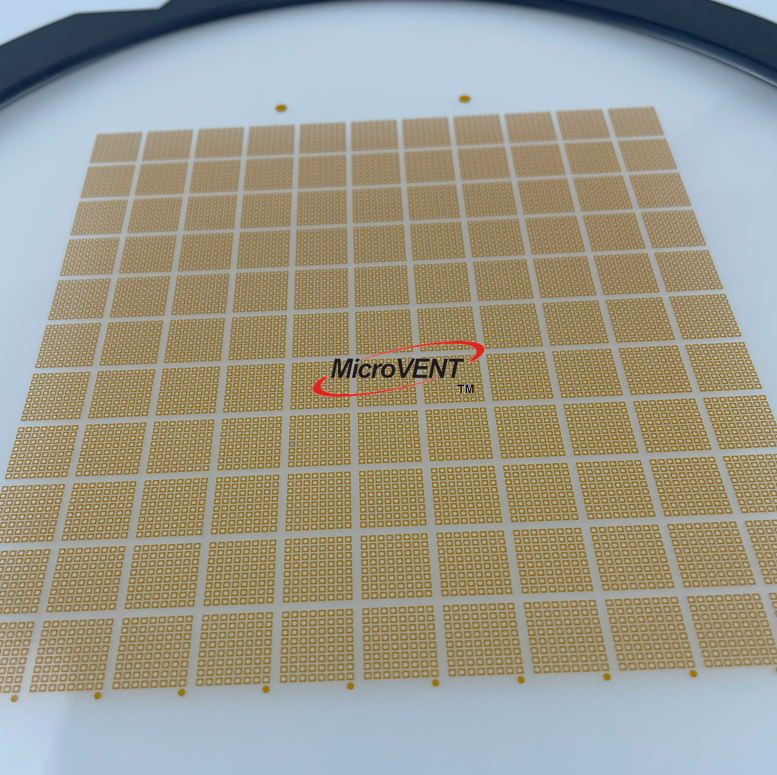

The acoustic ePTFE offers unprecedented versatility in installation and customization, making it adaptable to virtually any noise control challenge while simplifying the implementation process for engineers and installers. This flexibility begins with the material's inherent workability, as acoustic ePTFE can be easily cut, shaped, and formed using standard tools without requiring specialized equipment or extensive training. The material's conformability allows it to adapt to complex three-dimensional surfaces, irregular geometries, and tight spaces where rigid acoustic panels would be impossible to install. This adaptability proves particularly valuable in retrofit applications where existing structures must be modified with minimal disruption, as acoustic ePTFE can be contoured to fit around pipes, conduits, structural elements, and other obstacles. The customization possibilities extend to material properties, with acoustic ePTFE available in various thicknesses, densities, and pore structures to meet specific acoustic requirements. Engineers can select the optimal configuration based on frequency response needs, space constraints, and performance targets, ensuring the most effective solution for each application. Surface treatments and laminations can be applied to enhance specific properties or facilitate integration with other system components, such as adhesive backing for simplified installation or protective facings for harsh environments. The material's compatibility with various attachment methods, including mechanical fasteners, adhesives, and magnetic systems, provides installation flexibility while accommodating different substrate materials and structural requirements. Acoustic ePTFE can be integrated into composite structures, embedded within panels, or used as a standalone solution, offering design freedom that traditional materials cannot match. The ability to create custom shapes, perforations, and patterns enables architects and designers to incorporate acoustic treatment seamlessly into aesthetic designs without compromising visual appeal. This versatility extends to maintenance considerations, as acoustic ePTFE installations can be easily modified, relocated, or expanded as requirements change, providing long-term adaptability that rigid acoustic systems cannot offer. The combination of easy installation, customization options, and maintenance flexibility makes acoustic ePTFE an ideal solution for both new construction and retrofit projects across diverse industries and applications.