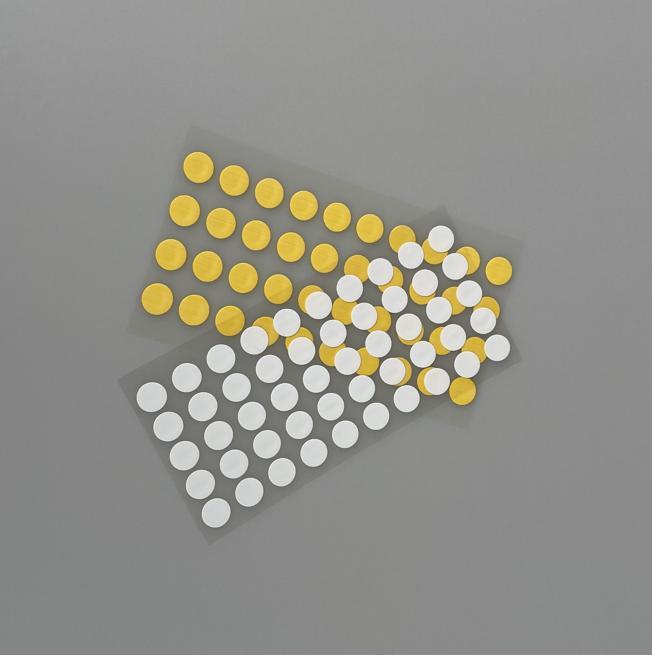

sensor membrane

The sensor membrane represents a revolutionary advancement in detection technology, serving as a critical interface between sensing elements and target environments. This sophisticated component functions as a selective barrier that enables precise measurement while protecting sensitive electronic components from harsh external conditions. At its core, the sensor membrane operates through selective permeability, allowing specific molecules or ions to pass through while blocking unwanted substances. This fundamental characteristic makes it essential for accurate readings across diverse applications ranging from medical diagnostics to industrial monitoring systems. The technological foundation of sensor membranes relies on advanced materials science, incorporating polymeric structures, ceramic composites, and specialized coatings that respond to environmental changes. These materials exhibit remarkable stability under varying temperature conditions, chemical exposure, and mechanical stress. The membrane's molecular structure can be engineered to detect specific gases, liquids, or biological markers with exceptional precision. Manufacturing processes involve sophisticated techniques such as spin coating, electrospinning, and layer-by-layer assembly to achieve optimal thickness and uniformity. Quality control measures ensure consistent performance characteristics including response time, selectivity, and durability. Applications span numerous industries including healthcare, environmental monitoring, food safety, automotive systems, and aerospace technology. In medical devices, sensor membranes enable glucose monitoring, blood gas analysis, and drug delivery systems. Environmental applications include air quality assessment, water contamination detection, and soil analysis. Industrial uses encompass process control, leak detection, and emissions monitoring. The versatility of sensor membrane technology continues expanding as researchers develop new materials and fabrication methods, making these components increasingly valuable for next-generation sensing solutions across multiple sectors.