Exceptional Durability and Longevity Performance

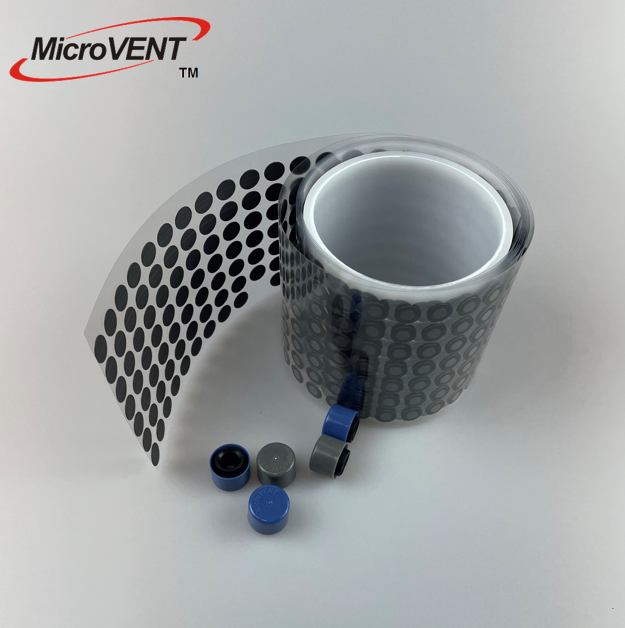

The breathable eptfe membrane sets new standards for material durability and longevity, delivering exceptional performance that far exceeds conventional alternatives in demanding applications. This remarkable durability stems from the inherent properties of expanded polytetrafluoroethylene, which maintains its molecular structure and performance characteristics even under extreme stress conditions. The membrane resists degradation from ultraviolet radiation, ozone exposure, and chemical attack, ensuring consistent performance throughout extended service periods. Mechanical testing demonstrates that the breathable eptfe membrane can withstand millions of flex cycles without developing cracks or performance deterioration, making it ideal for applications involving repeated movement and stress. The material exhibits outstanding resistance to abrasion and puncture, maintaining its integrity even when subjected to rough handling or sharp objects. Temperature cycling tests confirm that the breathable eptfe membrane maintains its properties through thousands of freeze-thaw cycles, demonstrating exceptional thermal shock resistance. This durability translates directly into cost savings for manufacturers and end users, as products incorporating the membrane require less frequent replacement and maintenance. The long-term stability of the breathable eptfe membrane means that performance specifications remain constant over years of operation, eliminating the gradual degradation common with other materials. Field testing in harsh environments including desert heat, arctic cold, and tropical humidity confirms that the membrane maintains its selective permeability and protective properties under real-world conditions. The durability extends to cleaning and sterilization processes, with the breathable eptfe membrane withstanding repeated exposure to steam, chemicals, and radiation without performance loss. This resilience enables use in medical applications where frequent sterilization is required, as well as industrial applications where harsh cleaning procedures are necessary. Quality control measures ensure that every breathable eptfe membrane meets strict durability standards, providing manufacturers and users with confidence in long-term performance and reliability.