Versatile Application Compatibility and Easy Installation

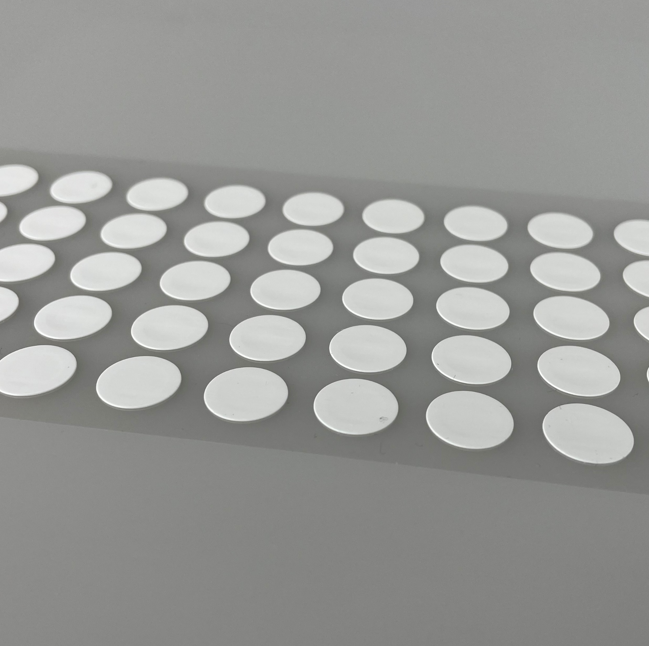

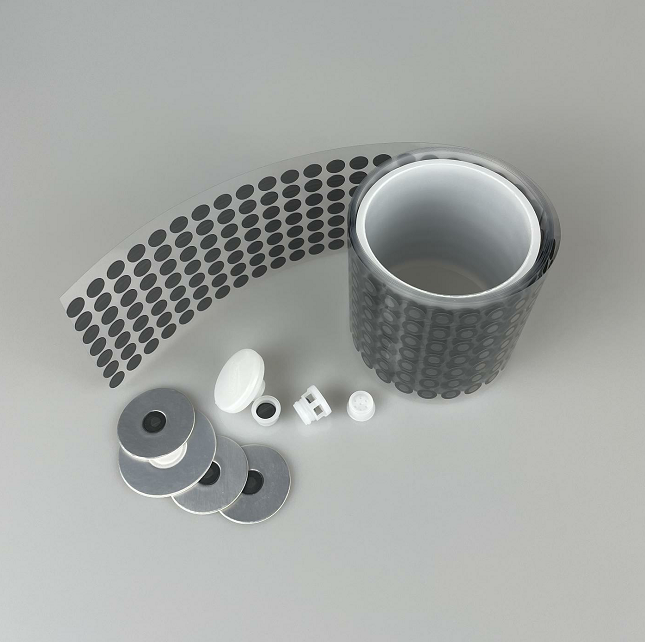

The remarkable versatility and installation simplicity of modern dustproof mesh systems enable seamless integration across an extensive range of applications, from compact consumer electronics to large-scale industrial equipment installations. This adaptability stems from comprehensive product line offerings that include various mesh sizes, mounting configurations, and material specifications designed to meet diverse protection requirements without compromising performance or aesthetics. The dustproof mesh compatibility extends across multiple industries, including information technology, automotive manufacturing, aerospace systems, medical equipment, and consumer appliances, demonstrating the universal applicability of this protective technology. Custom sizing options ensure that dustproof mesh can be precisely fitted to existing equipment openings, eliminating gaps or overlaps that could reduce protection effectiveness or create installation complications. The mounting system versatility accommodates different attachment methods, including magnetic mounting for easy removal and cleaning, adhesive backing for permanent installations, and mechanical fastening systems for high-vibration environments where secure attachment is critical. Installation procedures require minimal technical expertise, typically involving simple measurement, cutting, and attachment steps that can be completed using standard household or workshop tools. Comprehensive installation documentation accompanies dustproof mesh products, providing clear visual instructions and troubleshooting guidance that ensures successful implementation regardless of user experience level. The compatibility benefits extend to retrofit applications where existing equipment can be upgraded with dustproof mesh protection without requiring system modifications or component replacements. This retrofit capability proves particularly valuable for organizations seeking to protect legacy equipment investments while maintaining operational continuity. The mesh design flexibility allows for creative implementation approaches, including curved surface applications, multiple-opening coverage, and integration with existing ventilation or cooling systems. Quality control standards ensure that dustproof mesh products maintain consistent performance characteristics across different application environments, providing reliable protection regardless of specific use case requirements. The easy installation and removal capabilities facilitate regular maintenance procedures, allowing users to clean or replace mesh components quickly without disrupting equipment operations or requiring professional service intervention.