led eptfe membran

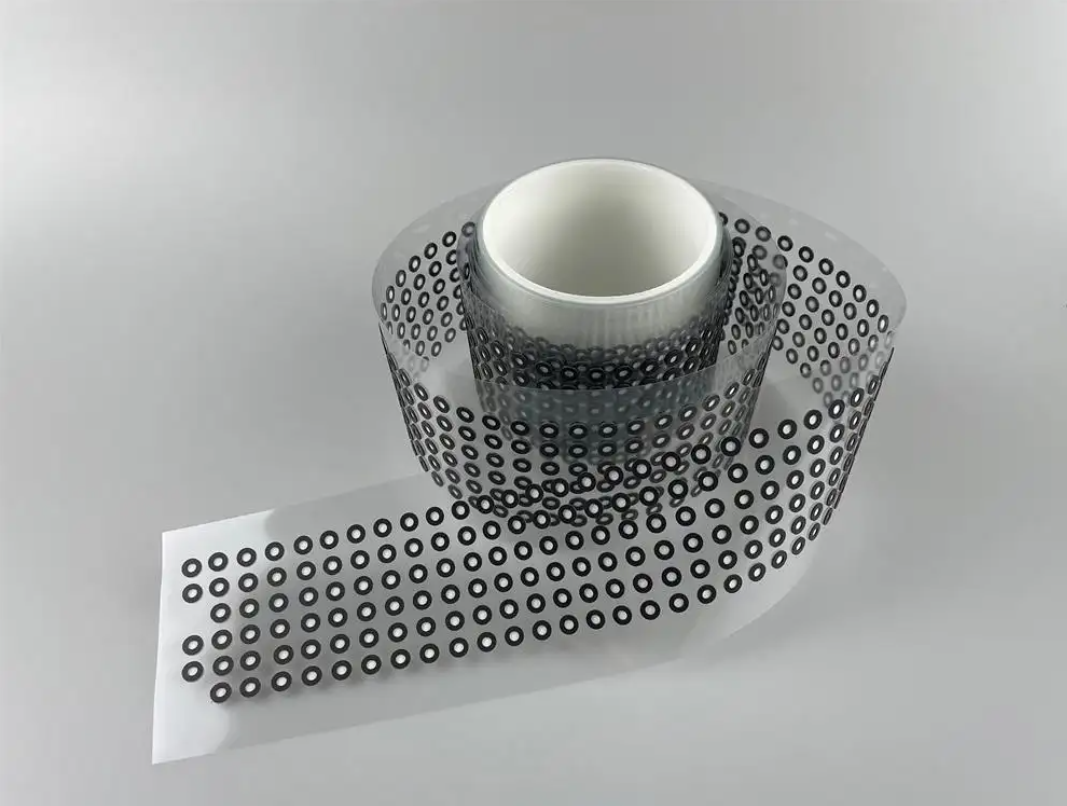

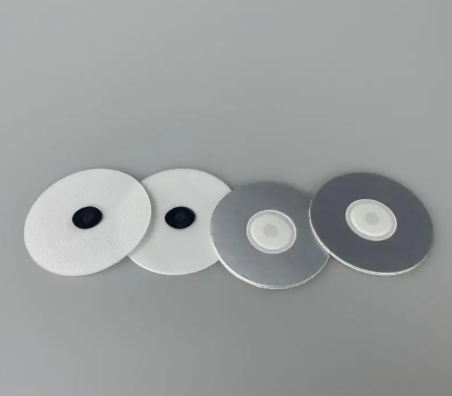

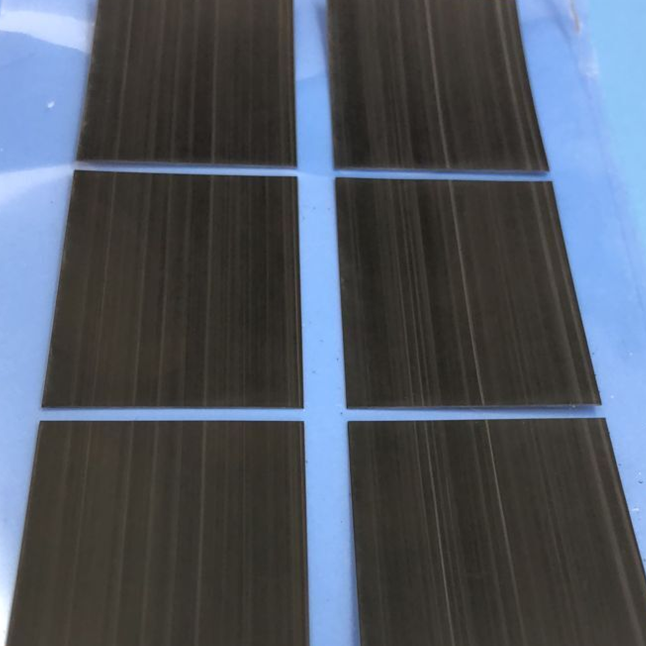

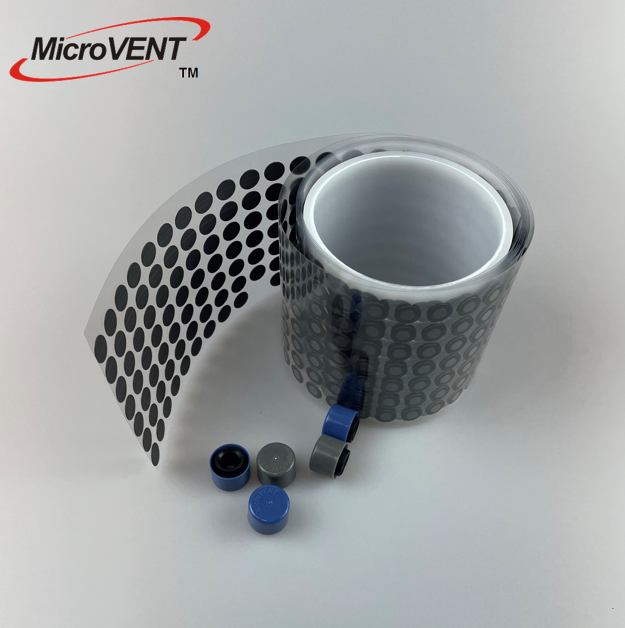

Led eptfe membran, genişletilmiş politetrafluoroetilenin olağanüstü özelliklerini yenilikçi üretim süreçleriyle birleştirerek filtrasyon ve bariyer teknolojisinde devrim niteliğinde bir ilerlemeyi temsil eder. Bu özel membran, çeşitli endüstriyel uygulamalarda üstün performans sağlayan benzersiz bir mikro gözenekli yapıya sahiptir. Led eptfe membran, mükemmel geçirgenlik özelliklerini korurken dikkat çekici derecede kimyasal direnç, termal stabilite ve mekanik dayanıklılık gösterir. Özellikli mikroyapısı, kontrollü gözenek boyutları oluşturarak hassas filtrasyon ve ayırma süreçlerine imkan tanıyan birbirine bağlı düğüm noktaları ve fibrillerden oluşur. Membranın hidrofobik yapısı, nem koruması gerektiren ancak gaz iletimine izin verilmesi gereken uygulamalar için özellikle uygundur. Üretim süreçleri, membranın gözenekliliğini optimize etmek ve malzeme boyunca tutarlı kalite sağlamak amacıyla dikkatle kontrol edilen genişletme tekniklerini içerir. Led eptfe membran, yüksek sıcaklıklar, agresif kimyasallar ve mekanik gerilim gibi aşırı çalışma koşullarında üstün dayanıklılık sergiler. Biyouyumlu özellikleri onu tıbbi ve farmasötik uygulamalar için uygun hale getirirken, elektrik yalıtım özellikleri elektronik bileşen korumasını destekler. Düşük sürtünme katsayısı ve yapışmaz yüzey özellikleri, çeşitli endüstriyel süreçlerde çok yönlülüğüne katkıda bulunur. İleri üretim yöntemleri, büyük membran alanlarında eşit kalınlık dağılımı ve tutarlı gözenek yapısını garanti eder. Led eptfe membran, zorlu ortamlarda güvenilir uzun vadeli çalışma imkanı sunarak uzun süreli kullanım sırasında performans özelliklerini korur. Hafif yapısı, sistemin toplam ağırlığını azaltırken olağanüstü performans avantajları sağlar. UV radyasyonuna ve atmosferik etkilere karşı direnci, dış mekan uygulamaları ve sert çevre koşulları için ideal hale getirir.

EN

EN

AR

AR

CS

CS

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

ID

ID

VI

VI

TH

TH

TR

TR

MS

MS