waterproof porous membrane

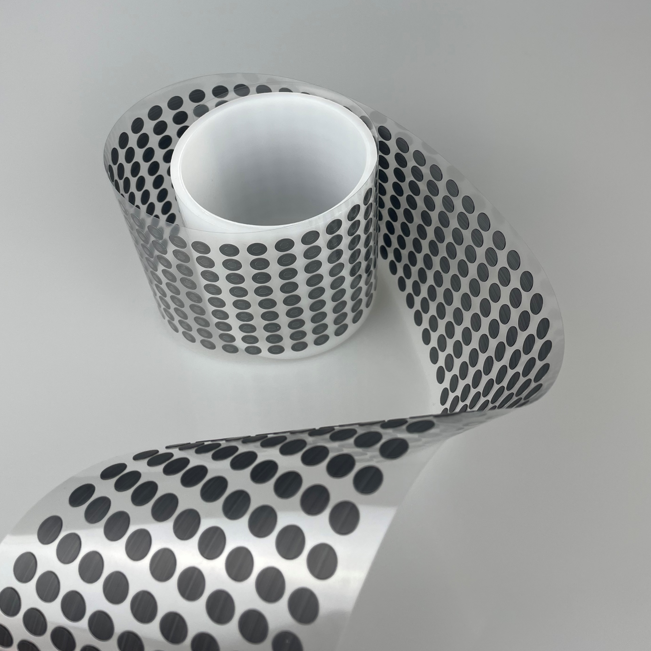

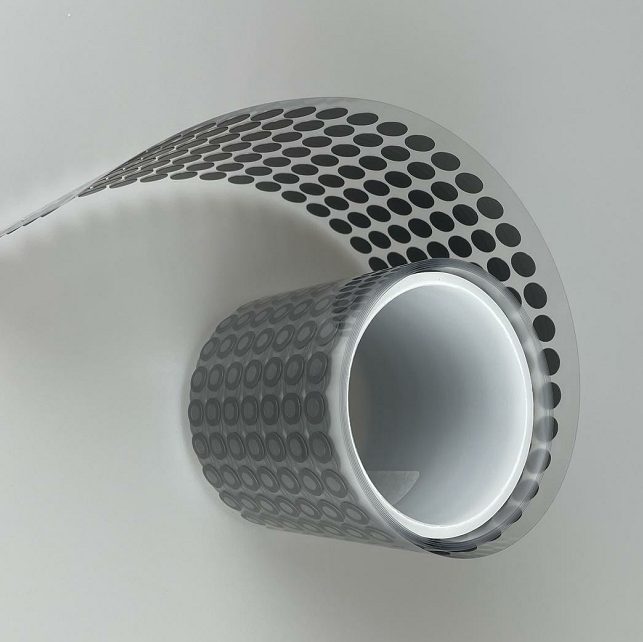

A waterproof porous membrane represents a revolutionary advancement in membrane technology, combining the seemingly contradictory properties of water resistance and breathability. This innovative material features a unique microstructure with billions of microscopic pores that are significantly smaller than water droplets but larger than water vapor molecules. The waterproof porous membrane operates on the fundamental principle of selective permeability, allowing water vapor to pass through while preventing liquid water penetration. The membrane typically consists of expanded polytetrafluoroethylene (ePTFE) or polyurethane materials, engineered to achieve optimal pore size distribution and structural integrity. Manufacturing processes involve stretching polymer films to create controlled microporous structures, resulting in membranes with exceptional durability and performance characteristics. The waterproof porous membrane functions by maintaining a delicate balance between hydrophobic surface properties and porous architecture. Water droplets cannot penetrate due to surface tension and contact angle effects, while water vapor molecules easily traverse the membrane through diffusion mechanisms. This technology finds extensive applications across multiple industries, including outdoor apparel, medical devices, automotive components, construction materials, and protective equipment. In textile applications, the waterproof porous membrane serves as a laminated layer between fabric layers, providing weather protection without compromising comfort. Medical applications utilize biocompatible versions for wound dressings, surgical drapes, and implantable devices. The construction industry employs these membranes in roofing systems, wall assemblies, and foundation waterproofing. Automotive manufacturers integrate waterproof porous membrane technology into vehicle components for moisture management and component protection. The membrane's versatility extends to electronics packaging, where it protects sensitive components while maintaining pressure equalization. Recent technological advancements have enhanced the waterproof porous membrane performance through nanotechnology integration, improved polymer formulations, and optimized manufacturing processes, resulting in superior water resistance, breathability, and longevity.