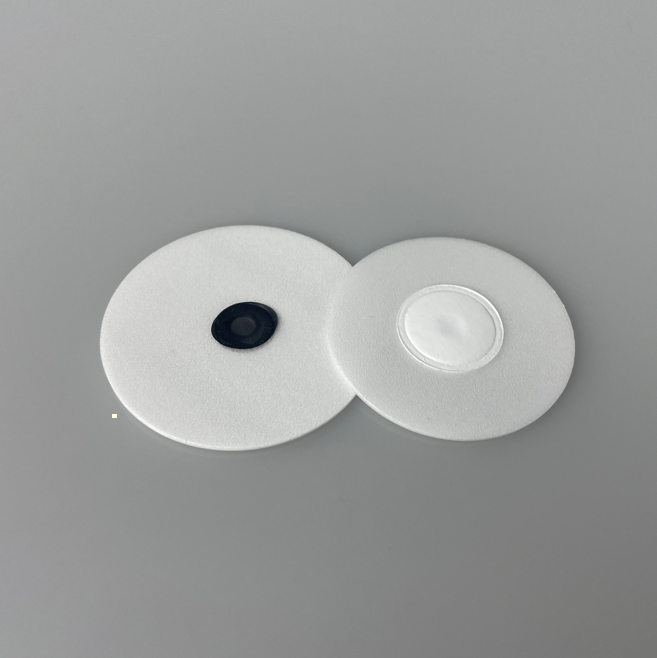

vent cap gasket

A vent cap gasket serves as a critical sealing component designed to create an airtight barrier between vent caps and their mounting surfaces. This essential hardware component plays a pivotal role in maintaining proper ventilation systems while preventing unwanted air infiltration, moisture penetration, and debris entry. The vent cap gasket operates by forming a compressed seal when positioned between the vent cap assembly and the roof or wall surface, ensuring optimal performance of ventilation systems across residential, commercial, and industrial applications. Modern vent cap gaskets incorporate advanced elastomeric materials that provide exceptional flexibility and durability under varying environmental conditions. These gaskets feature weather-resistant properties that withstand temperature fluctuations, UV exposure, and harsh weather elements without compromising their sealing integrity. The technological design of vent cap gaskets includes precision-engineered dimensions that accommodate standard vent cap configurations while maintaining consistent compression characteristics throughout their service life. Manufacturing processes utilize high-grade synthetic rubber compounds, EPDM materials, or specialized polymer blends that deliver superior resistance to ozone, chemicals, and thermal cycling. The gasket's surface texture and profile geometry are specifically engineered to maximize contact area and minimize stress concentrations during installation and operation. Installation of vent cap gaskets requires minimal tools and expertise, making them accessible for both professional contractors and DIY enthusiasts. The gasket's flexibility allows for easy positioning and adjustment during mounting procedures, while its resilient properties ensure long-term performance reliability. Quality vent cap gaskets undergo rigorous testing protocols to verify their performance under simulated weather conditions, compression loads, and aging scenarios. These testing procedures validate the gasket's ability to maintain effective sealing properties over extended periods while resisting common failure modes such as cracking, hardening, or dimensional changes. The vent cap gasket represents an economical insurance policy against costly moisture damage, energy loss, and system inefficiencies that can result from inadequate sealing solutions.