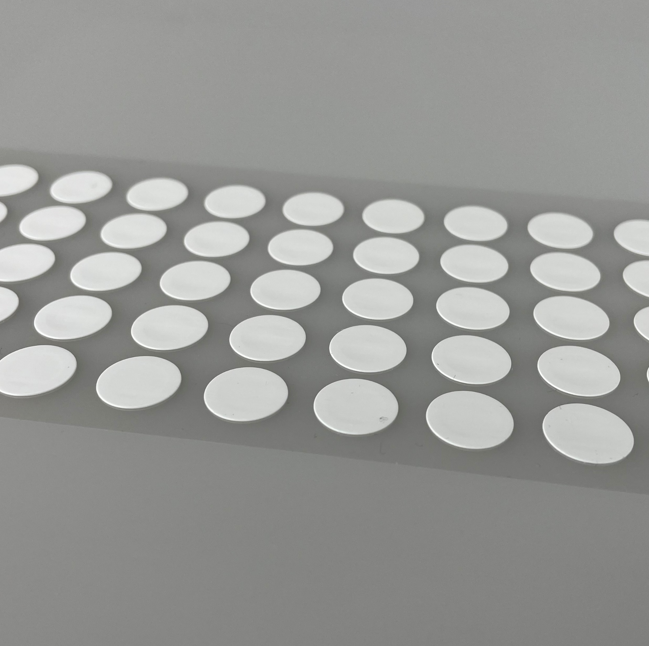

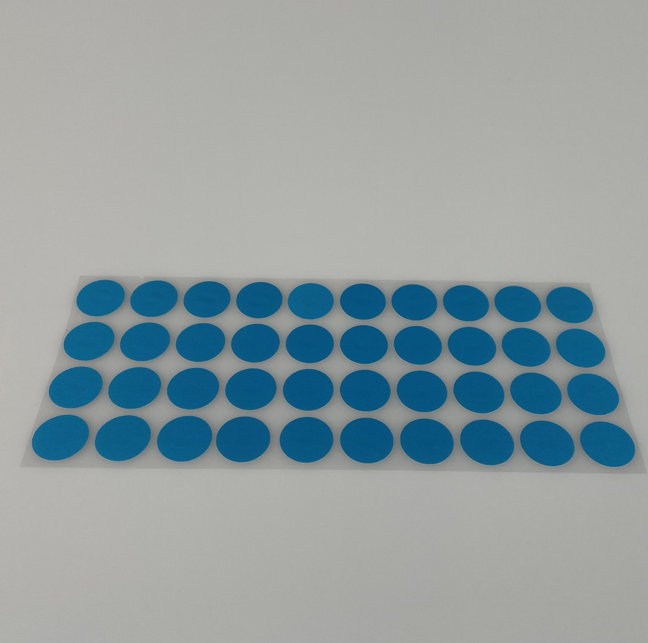

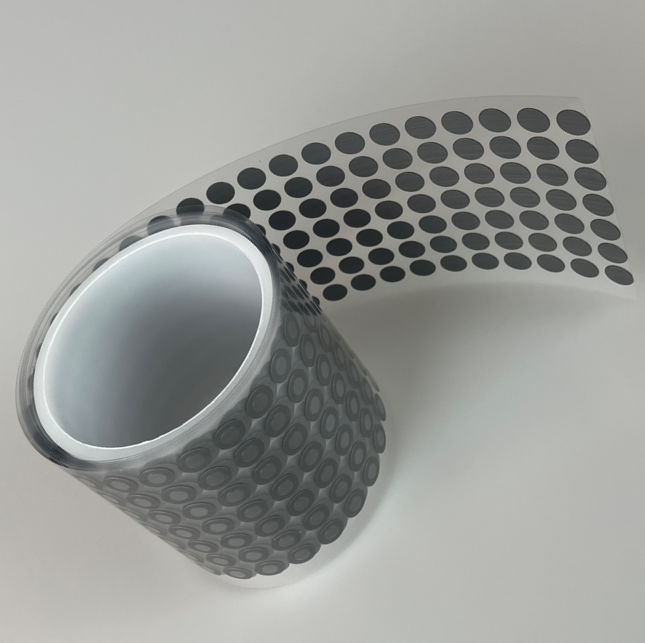

gore eptfe membrane

The gore eptfe membrane represents a revolutionary advancement in membrane technology, engineered from expanded polytetrafluoroethylene (ePTFE) materials that deliver exceptional performance across diverse industrial applications. This sophisticated membrane system combines breathability with waterproof protection, making it an ideal solution for filtration, protective clothing, and medical device applications. The gore eptfe membrane features a unique microporous structure that allows vapor transmission while blocking liquid penetration, creating a selective barrier that maintains optimal environmental conditions. Manufacturing processes involve stretching PTFE materials to create controlled porosity, resulting in membranes with precise pore sizes ranging from 0.1 to 50 microns depending on specific application requirements. The technological foundation of gore eptfe membrane systems relies on advanced polymer science, where fluorinated carbon chains provide chemical inertness and thermal stability. These membranes demonstrate remarkable durability under extreme conditions, maintaining structural integrity across temperature ranges from -200°C to 260°C. The gore eptfe membrane exhibits exceptional chemical resistance, remaining unaffected by acids, bases, solvents, and other aggressive substances that would degrade conventional membrane materials. Applications span numerous industries including aerospace, automotive, electronics, pharmaceuticals, and outdoor recreation, where reliable barrier protection is essential. The membrane's hydrophobic properties ensure consistent performance in humid environments, while its oleophobic characteristics provide resistance to oil-based contaminants. Manufacturing quality control ensures consistent pore distribution and membrane thickness, delivering predictable performance characteristics across production batches. The gore eptfe membrane technology incorporates specialized surface treatments that enhance specific properties such as antimicrobial resistance or improved adhesion characteristics. These membranes support sustainable manufacturing practices through their longevity and recyclability, reducing environmental impact compared to disposable alternatives.