Advanced Environmental Protection Technology

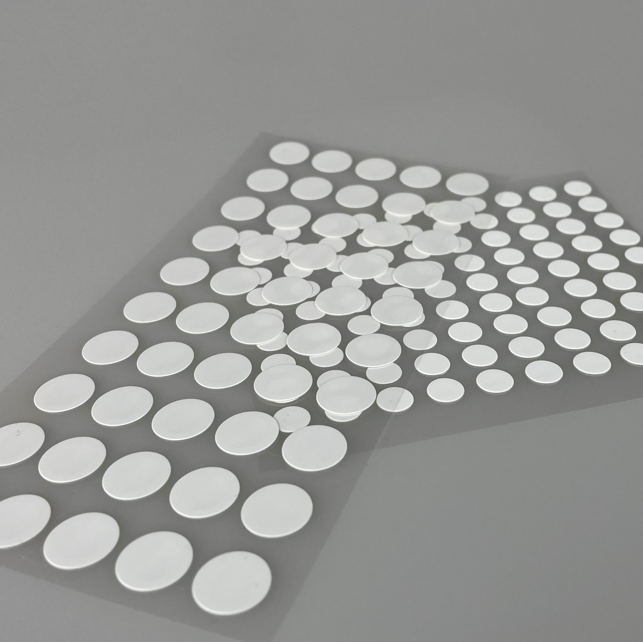

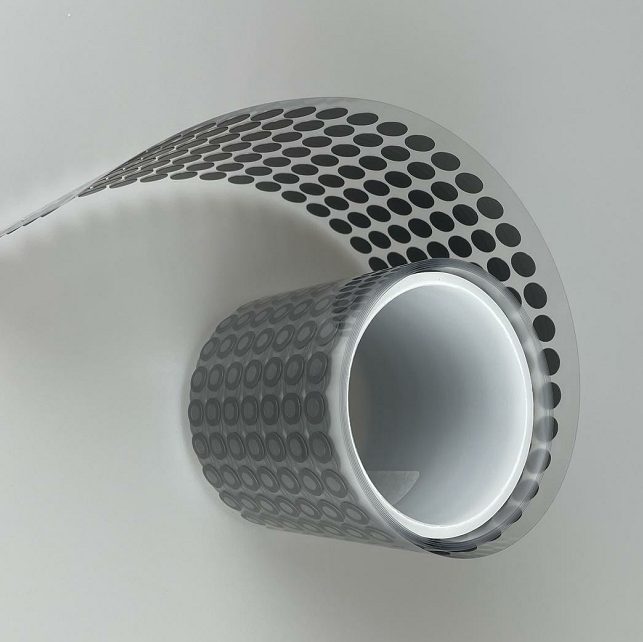

The protective membrane motor's most distinctive feature lies in its cutting-edge environmental protection technology, which revolutionizes how motors withstand harsh operating conditions. This sophisticated protection system utilizes multiple layers of specialized membrane materials, each engineered to address specific environmental threats while maintaining optimal motor performance. The primary membrane layer acts as a selective barrier, effectively blocking moisture penetration while allowing controlled air exchange necessary for thermal management. Secondary protection layers provide chemical resistance against acids, bases, solvents, and other corrosive substances commonly encountered in industrial environments. The membrane technology incorporates advanced polymer science, utilizing materials that maintain flexibility across extreme temperature ranges while retaining their protective properties. This multi-layered approach ensures comprehensive protection against environmental factors that typically cause motor failures, including salt spray in marine applications, chemical vapors in processing facilities, and abrasive particles in mining operations. The protective membrane motor's environmental protection extends beyond simple sealing, featuring dynamic adaptation to changing conditions through smart membrane materials that respond to temperature and pressure variations. This adaptive capability ensures consistent protection regardless of operational fluctuations, maintaining sealed integrity even during thermal cycling or pressure changes. The membrane system includes integrated sensors that monitor environmental conditions and membrane performance, providing early warning of potential protection compromises. This proactive monitoring enables maintenance teams to address issues before they impact motor operation, significantly extending equipment lifespan. The environmental protection technology also incorporates self-healing capabilities in certain membrane materials, allowing minor punctures or wear to automatically seal, maintaining protection integrity. The protective membrane motor's environmental shielding surpasses traditional IP ratings, offering protection levels that adapt to specific application requirements rather than fixed standards. This customizable protection makes the protective membrane motor suitable for unique environmental challenges where standard protection methods prove inadequate, providing tailored solutions for specialized industrial applications.