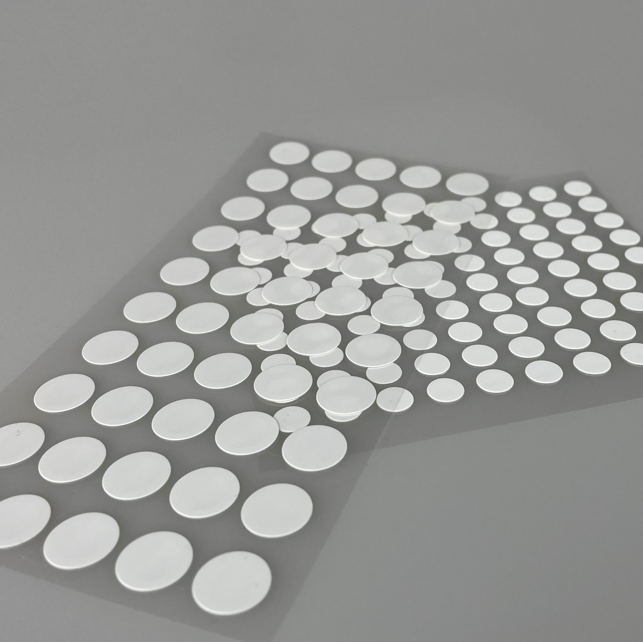

air permeable eptfe

Air permeable ePTFE represents a revolutionary breakthrough in membrane technology, combining exceptional breathability with superior barrier protection. This advanced material, derived from expanded polytetrafluoroethylene, delivers unprecedented performance across diverse industrial and consumer applications. The unique microporous structure of air permeable ePTFE creates millions of tiny interconnected pores that allow air and water vapor to pass through while effectively blocking liquid water, dust particles, and other contaminants. This selective permeability makes air permeable ePTFE an ideal solution for applications requiring both protection and ventilation. The manufacturing process involves stretching PTFE in multiple directions, creating a matrix of nodes and fibrils that form the characteristic porous structure. This engineered architecture enables air permeable ePTFE to maintain consistent airflow rates while providing reliable barrier properties. The material exhibits remarkable chemical resistance, withstanding exposure to acids, bases, solvents, and extreme temperatures without degradation. Air permeable ePTFE finds extensive use in outdoor gear, automotive components, electronics enclosures, medical devices, and industrial filtration systems. Its ability to prevent water ingress while allowing internal pressure equalization makes it essential for sealed electronic enclosures, preventing condensation buildup and component damage. In automotive applications, air permeable ePTFE protects sensitive sensors and control modules from moisture while maintaining proper ventilation. The textile industry leverages this technology in high-performance fabrics for outdoor clothing, ensuring wearer comfort through moisture management. Medical applications benefit from the biocompatible nature of air permeable ePTFE, making it suitable for implantable devices and wound care products. Industrial uses include breather vents, filtration membranes, and protective barriers where contamination control is critical.