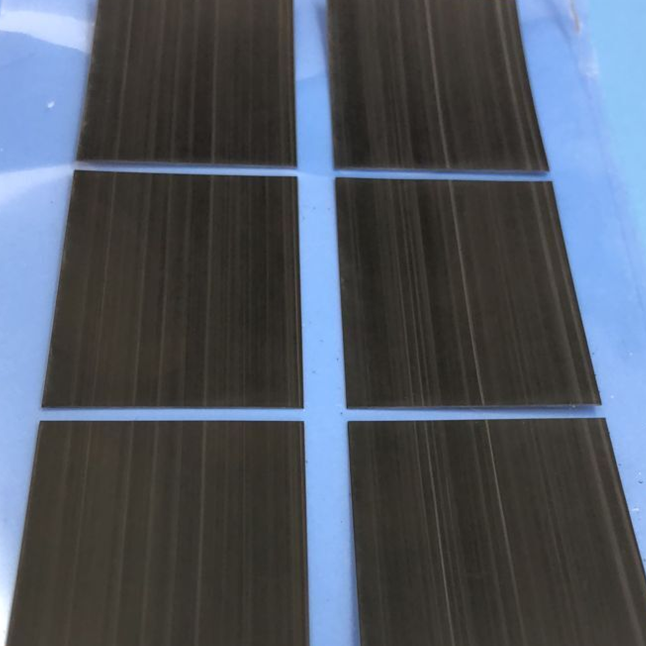

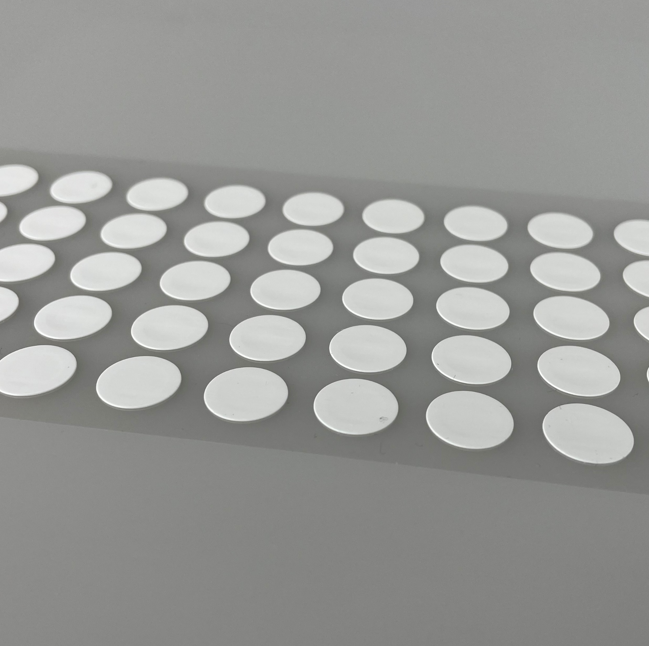

vent sticker

The vent sticker represents a revolutionary advancement in adhesive ventilation technology, designed specifically for applications requiring controlled airflow management while maintaining secure adhesion. This innovative product combines specialized microporous membrane technology with high-performance adhesive compounds to create a unique solution that allows gases and vapors to pass through while preventing liquid penetration. The vent sticker features a carefully engineered structure consisting of multiple layers, including a breathable membrane core, protective backing material, and precision-formulated adhesive coating. The primary function of this advanced vent sticker revolves around pressure equalization, moisture management, and contamination prevention in sealed environments. Its technological framework incorporates hydrophobic and oleophobic properties, ensuring that while air molecules can freely traverse the membrane, water droplets and oil-based substances remain blocked. The applications for vent sticker technology span across diverse industries, from automotive and electronics to medical devices and packaging solutions. In automotive applications, the vent sticker serves as a critical component for headlight assemblies, preventing condensation buildup while allowing pressure changes during temperature fluctuations. Electronic enclosures benefit significantly from vent sticker integration, as these devices require protection from moisture ingress while maintaining internal pressure balance. The medical industry utilizes vent sticker technology in sterile packaging, where maintaining sterility while allowing ethylene oxide sterilization gases to penetrate and evacuate is essential. Manufacturing processes incorporate vent sticker solutions for quality control and product integrity maintenance. The dimensional stability and chemical resistance of modern vent sticker designs ensure long-term performance under challenging environmental conditions, including extreme temperatures, humidity variations, and exposure to various chemical substances.