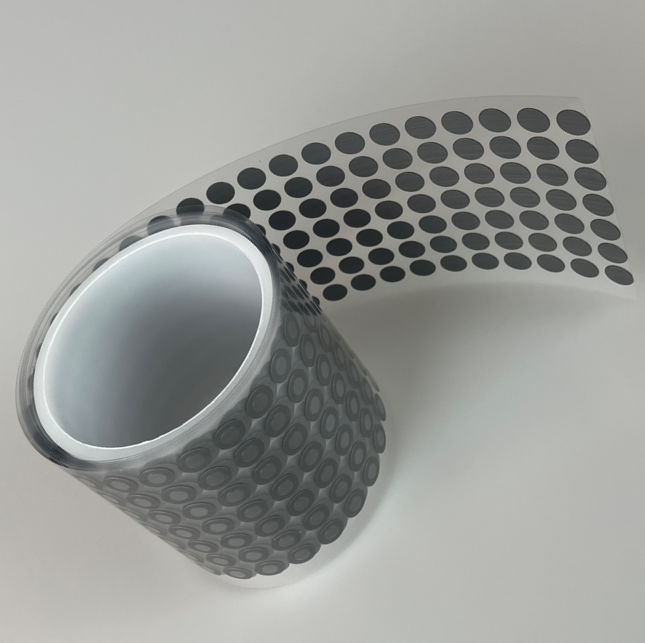

adhesive eptfe membrane

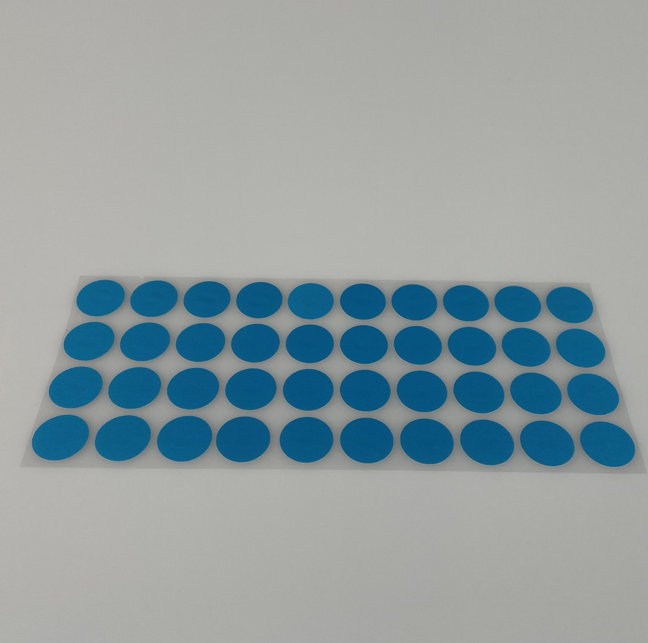

The adhesive eptfe membrane represents a revolutionary advancement in membrane technology, combining the exceptional properties of expanded polytetrafluoroethylene with specialized adhesive capabilities. This innovative material features a unique microporous structure that delivers outstanding performance across diverse industrial applications. The adhesive eptfe membrane maintains the fundamental characteristics of traditional ePTFE while incorporating enhanced bonding properties that eliminate the need for additional adhesive layers or mechanical fastening systems. The membrane's distinctive architecture consists of interconnected nodes and fibrils that create a three-dimensional network, providing exceptional strength and flexibility. This structure enables the adhesive eptfe membrane to withstand extreme temperatures, chemical exposure, and mechanical stress while maintaining its integrity and performance. The manufacturing process involves careful control of expansion parameters and adhesive integration to ensure consistent quality and reliable performance. Key technological features include superior breathability, allowing gases and vapors to pass through while blocking liquids and particulates. The adhesive component is strategically integrated to provide strong bonding without compromising the membrane's filtration properties. Temperature resistance ranges from -200°C to +260°C, making the adhesive eptfe membrane suitable for extreme environmental conditions. The material demonstrates excellent chemical inertness, resisting degradation from acids, bases, solvents, and other aggressive chemicals. Applications span multiple industries including automotive, electronics, medical devices, industrial filtration, and protective equipment. In automotive applications, the adhesive eptfe membrane serves as a critical component in fuel tank ventilation systems, transmission breathers, and electronic housing protection. The electronics industry utilizes these membranes for device protection against moisture and contaminants while maintaining pressure equalization. Medical applications benefit from the membrane's biocompatibility and sterilization resistance, making it ideal for diagnostic equipment and protective barriers.