automotive ecu membrane

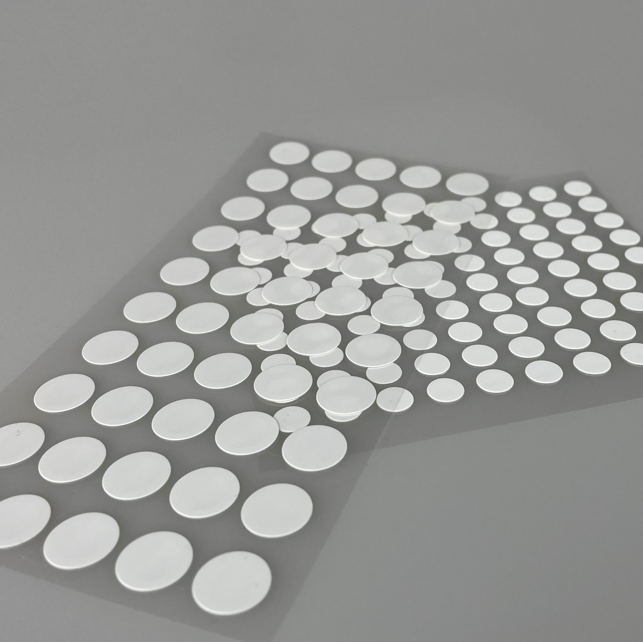

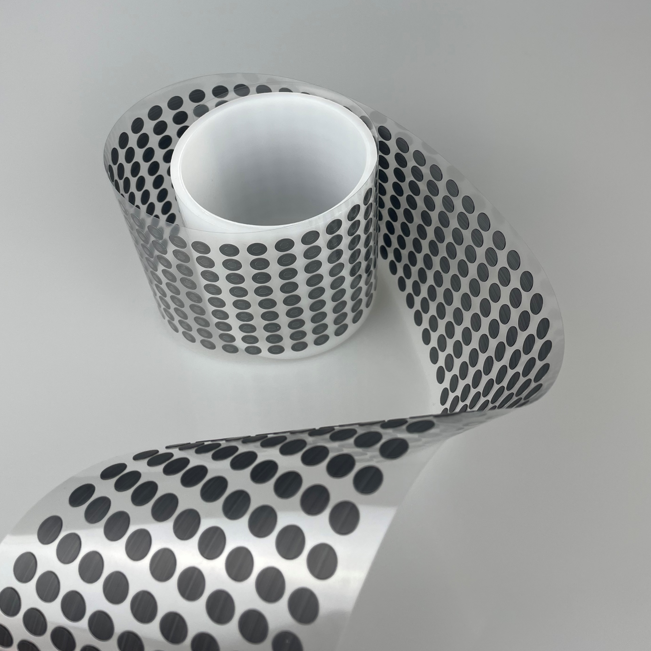

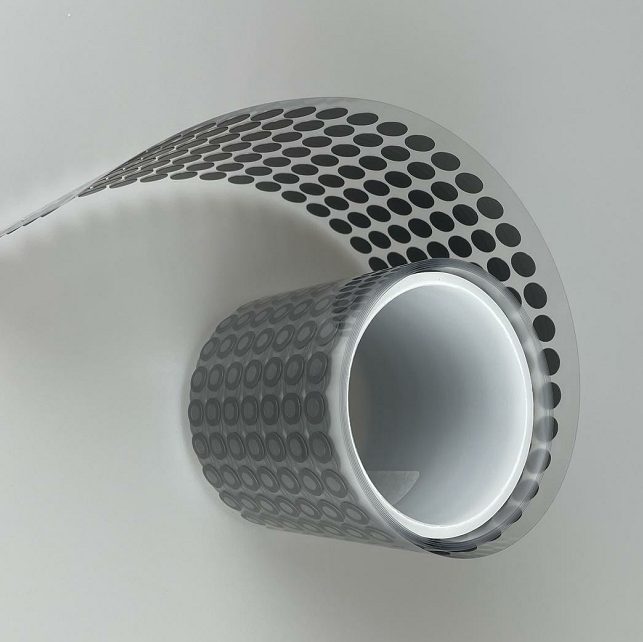

The automotive ecu membrane represents a critical component in modern vehicle electronic control systems, serving as a protective barrier for Electronic Control Unit circuits and sensitive electronic components. This specialized membrane technology provides essential protection against environmental hazards while maintaining optimal electrical performance in demanding automotive conditions. The automotive ecu membrane functions as a waterproof seal that prevents moisture infiltration, dust contamination, and chemical exposure that could compromise ECU functionality. Its primary role involves creating a reliable barrier between delicate electronic circuits and harsh automotive environments, including temperature fluctuations, vibrations, and corrosive substances. The membrane incorporates advanced materials engineered specifically for automotive applications, featuring excellent thermal stability and chemical resistance properties. Modern automotive ecu membrane designs utilize multi-layer construction techniques that combine different materials to achieve superior protection levels. These membranes typically include breathable elements that allow pressure equalization while blocking liquid penetration, preventing condensation buildup inside ECU housings. The technological features of automotive ecu membrane systems include precise thickness control, consistent porosity, and enhanced durability under mechanical stress. Manufacturing processes involve sophisticated lamination techniques that ensure uniform material distribution and eliminate weak points that could lead to failure. Applications for automotive ecu membrane technology span across various vehicle systems, including engine management units, transmission control modules, brake system controllers, and advanced driver assistance systems. The membrane technology proves particularly valuable in hybrid and electric vehicles where high-voltage electronics require maximum protection from environmental factors. Installation procedures for automotive ecu membrane components demand precise positioning and proper sealing techniques to ensure long-term reliability and optimal performance in challenging automotive operating conditions.