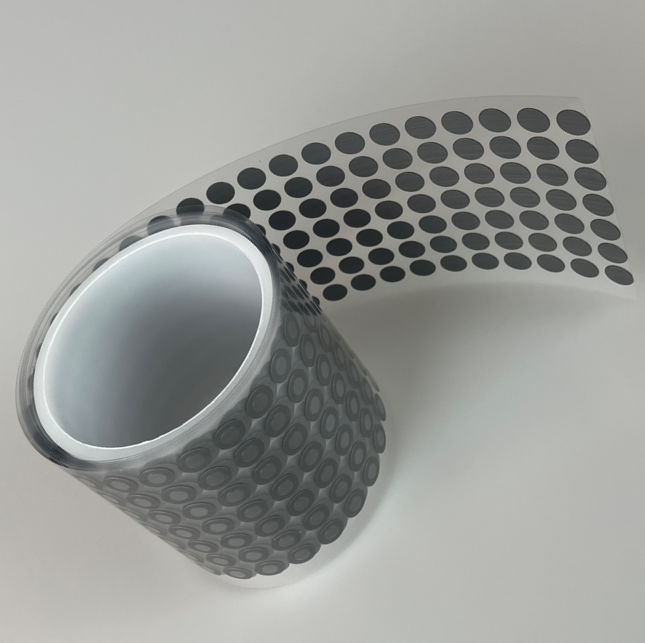

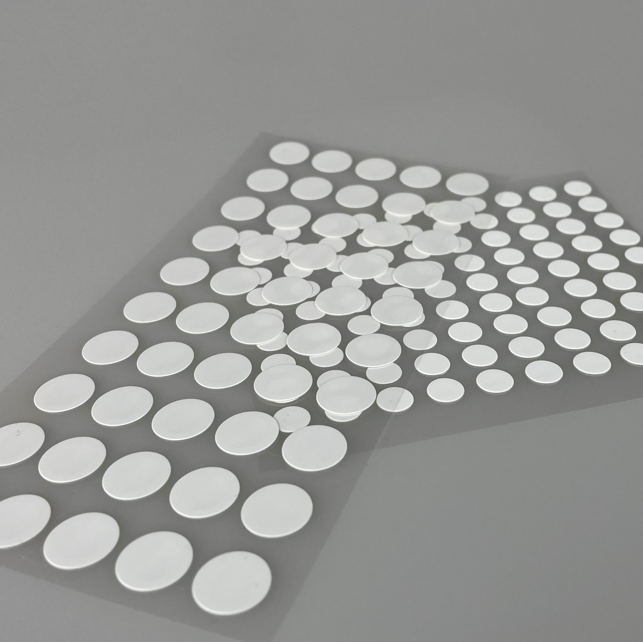

air release membrane

The air release membrane represents a sophisticated filtration technology designed to facilitate controlled gas separation while maintaining optimal system performance across diverse industrial applications. This innovative membrane technology operates through selective permeability principles, allowing targeted gases to pass through while effectively retaining desired substances on the opposing side. The primary function of an air release membrane centers on degassing operations, where dissolved gases must be removed from liquid systems to prevent operational complications and maintain product quality standards. These membranes utilize advanced microporous structures that create pathways for gas molecules while blocking larger particles and liquid components. The technological foundation relies on material science innovations that produce consistent pore sizes and distribution patterns, ensuring reliable performance under varying operational conditions. Air release membranes find extensive use in pharmaceutical manufacturing, where sterile filtration processes require precise gas removal without compromising product integrity. Additionally, these membranes serve critical roles in biotechnology applications, laboratory equipment, analytical instruments, and industrial processing systems where gas contamination poses significant challenges. The membrane construction typically involves specialized polymeric materials engineered to withstand chemical exposure, temperature variations, and mechanical stress while maintaining structural integrity over extended operational periods. Modern air release membrane designs incorporate hydrophobic properties that prevent liquid breakthrough while maximizing gas permeability rates. Installation flexibility allows integration into existing systems with minimal modifications, making these membranes attractive solutions for retrofit applications and new system designs. Performance characteristics include consistent flow rates, predictable pressure differentials, and reliable long-term stability that reduces maintenance requirements and operational costs.