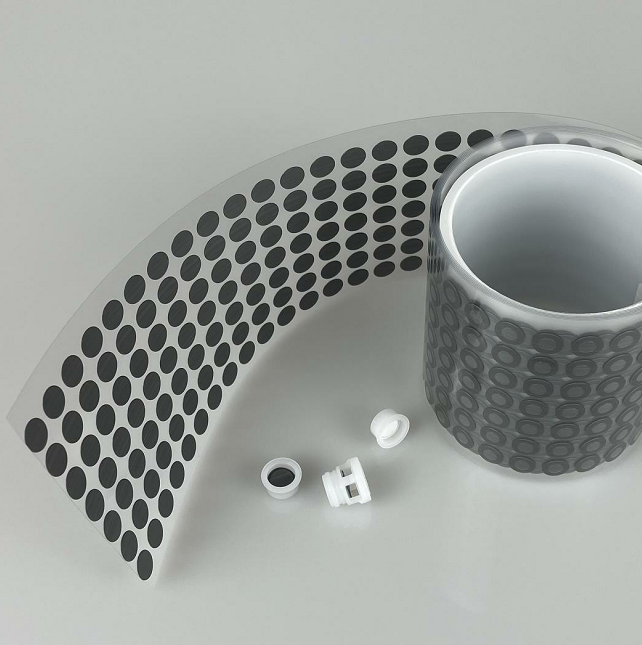

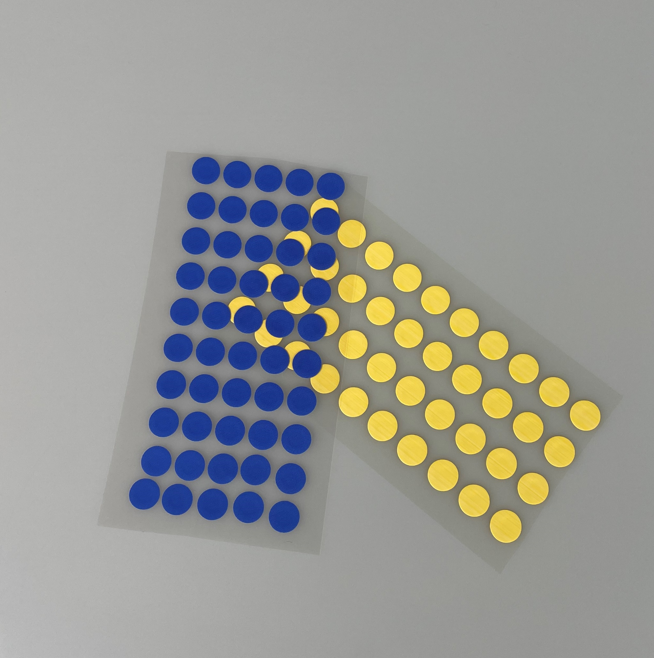

porous film

Porous film represents a revolutionary advancement in membrane technology, characterized by its unique structure featuring microscopic pores that enable selective permeability while maintaining structural integrity. This innovative material consists of a thin polymer matrix with precisely controlled pore sizes ranging from nanometers to micrometers, allowing for customized filtration and separation capabilities. The porous film technology serves multiple critical functions across various industries, primarily focusing on filtration, separation, and barrier applications. Its main technological features include exceptional porosity control, uniform pore distribution, and remarkable chemical resistance properties. The manufacturing process involves sophisticated techniques such as phase inversion, track etching, or electrospinning, resulting in films with tailored characteristics specific to intended applications. These films demonstrate outstanding performance in gas separation processes, liquid filtration systems, and protective barrier applications. The versatility of porous film extends to numerous sectors including water treatment facilities, pharmaceutical manufacturing, food processing, electronics production, and medical device applications. In water treatment applications, porous film effectively removes contaminants, bacteria, and particulates while allowing clean water molecules to pass through efficiently. The pharmaceutical industry utilizes these films for drug delivery systems, sterile filtration, and biomedical separation processes. Food processing applications benefit from the film's ability to maintain product quality through selective permeability and contamination prevention. Electronics manufacturing employs porous film for component protection and environmental isolation. Medical applications include wound dressings, surgical membranes, and diagnostic devices where controlled permeability proves essential for optimal performance and patient safety.