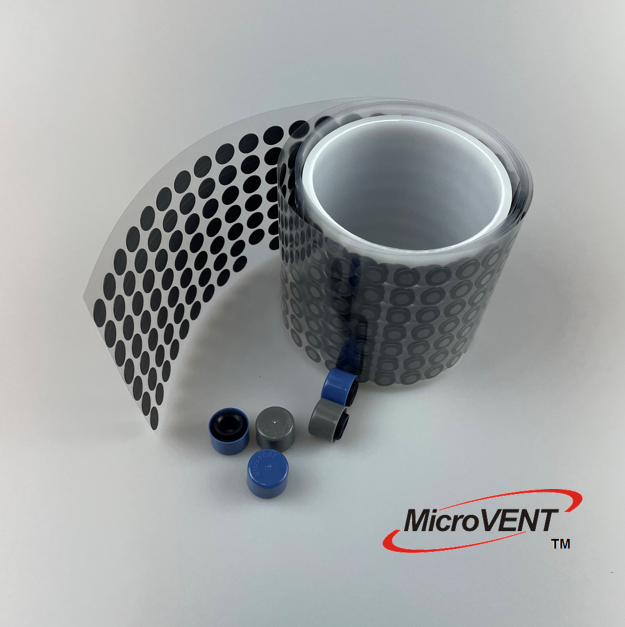

Versatile Integration and Cost-Effective Implementation Solutions

The microvent membrane offers exceptional versatility in integration applications, providing manufacturers with flexible solutions that streamline production processes while delivering superior performance characteristics across diverse industry sectors. Design engineers appreciate the membrane's compatibility with various substrates including metals, plastics, composites, and textiles, enabling integration into existing product architectures without requiring extensive modifications or specialized attachment methods. The self-adhesive backing system eliminates the need for additional fastening hardware or complex installation procedures, reducing assembly time and labor costs while ensuring consistent, reliable attachment. Manufacturing flexibility extends to customization options, where the microvent membrane can be die-cut to precise dimensions, shaped to complex geometries, or laminated with other materials to create multi-functional barrier systems. This adaptability makes the membrane suitable for applications ranging from small electronic devices requiring miniaturized venting solutions to large industrial equipment needing extensive pressure equalization. Cost-effectiveness becomes apparent through multiple factors including reduced inventory requirements due to standardized specifications, simplified procurement processes, and decreased quality control complexity. The membrane's consistent performance characteristics eliminate the variability often associated with alternative solutions, reducing rejection rates and improving production yields. Supply chain advantages include reliable availability, consistent quality standards, and comprehensive technical support that assists manufacturers in optimizing their implementation strategies. The membrane's lightweight properties contribute to overall product weight reduction, which is particularly valuable in automotive and aerospace applications where weight savings translate directly to improved efficiency and performance. Installation training requirements are minimal due to the straightforward application process, reducing onboarding costs for production personnel. The membrane's shelf stability and storage requirements are less demanding than many alternative materials, reducing inventory management complexity and storage costs. Technical documentation and application guidelines facilitate rapid integration into new product designs, reducing development time and time-to-market for innovative products. Post-installation performance monitoring is simplified through the membrane's predictable behavior patterns, enabling more accurate maintenance scheduling and reducing unexpected downtime costs.