Superior Contamination Protection

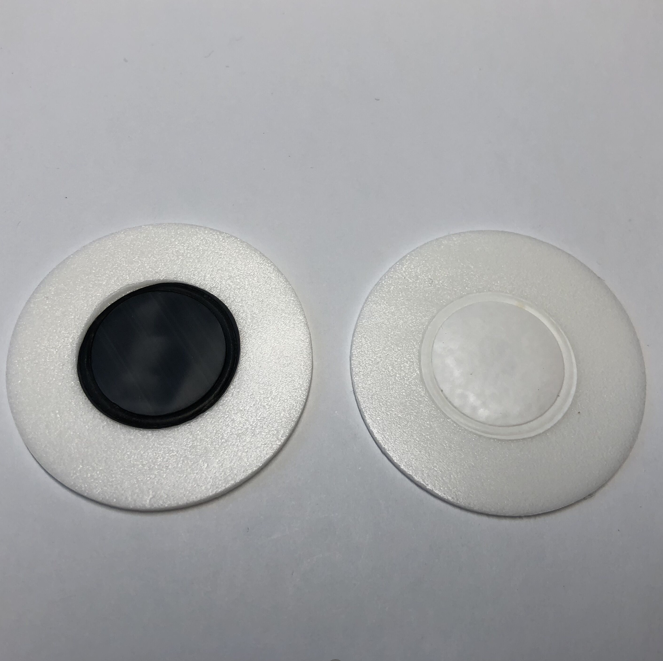

The vent pe seal provides exceptional contamination protection through its advanced filtration design that allows necessary air exchange while blocking harmful particles, moisture, and microorganisms from entering the sealed environment. This multi-layered protection system combines physical barriers with chemical resistance properties to create an impermeable shield against contaminants that could compromise product quality or safety. The seal's microporous structure is engineered to allow gas molecules to pass through while preventing larger particles, bacteria, and liquid droplets from penetrating the barrier. This selective permeability ensures that pressure equalization occurs without exposing the contents to environmental contaminants that could cause spoilage, corrosion, or degradation. The polyethylene material used in vent pe seal construction offers natural resistance to chemicals, oils, and moisture, providing an additional layer of protection against aggressive substances that might be encountered during storage or transportation. Testing protocols demonstrate that the seal maintains its barrier properties even when exposed to extreme humidity, temperature variations, and chemical vapors commonly found in industrial environments. The contamination protection extends to particulate matter, including dust, pollen, and industrial pollutants that could affect sensitive products such as electronics, pharmaceuticals, or precision instruments. The seal's design incorporates features that prevent backflow contamination, ensuring that once contaminants are blocked, they cannot enter the package even under reverse pressure conditions. This comprehensive protection system significantly extends product shelf life and maintains quality standards required for regulated industries, reducing waste and improving customer satisfaction while meeting strict safety requirements.