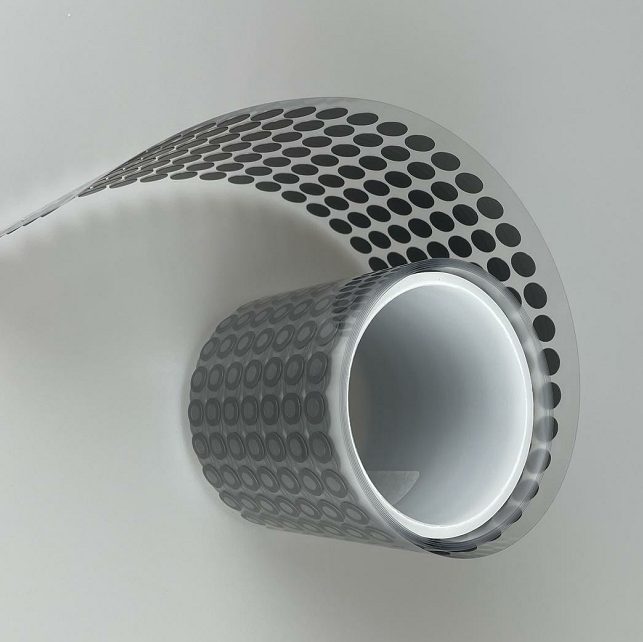

vent filter

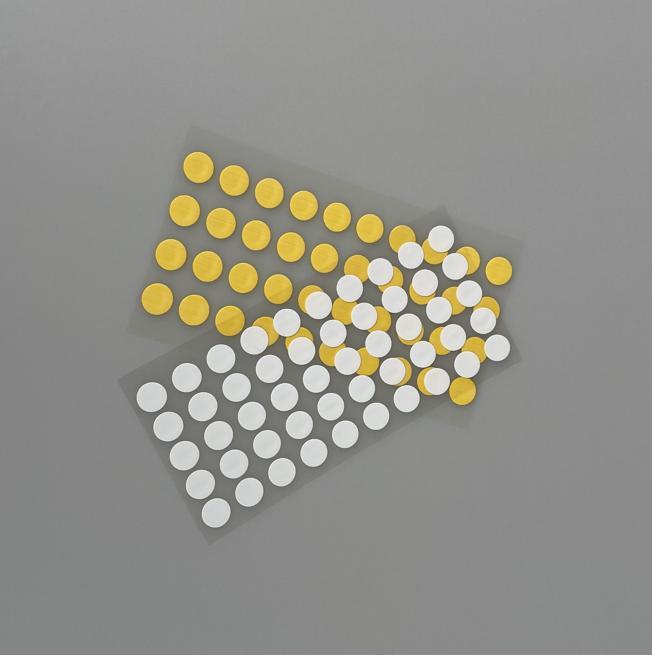

A vent filter represents an essential component in modern air management systems, designed to maintain clean air circulation while preventing contaminants from entering enclosed spaces. This sophisticated filtration device operates by allowing controlled airflow while capturing particles, dust, moisture, and other airborne pollutants that could compromise air quality or equipment performance. The vent filter utilizes advanced filtration media, typically composed of high-efficiency synthetic materials or pleated designs that maximize surface area for optimal particle capture. These filters incorporate multiple layers of filtration technology, including pre-filters for larger particles and fine filters for microscopic contaminants. The structural design features durable housing materials that withstand various environmental conditions, ensuring long-term reliability in diverse applications. Technological innovations in vent filter development have led to enhanced filtration efficiency ratings, often exceeding HEPA standards for critical applications. The filter mechanism works through mechanical filtration, electrostatic attraction, and sometimes activated carbon absorption, depending on specific requirements. Installation versatility allows for integration into HVAC systems, cleanrooms, industrial ventilation, automotive applications, and residential air quality systems. The vent filter maintains consistent airflow rates while providing protection against biological contaminants, chemical vapors, and particulate matter. Regular maintenance schedules ensure optimal performance, with replaceable filter elements designed for easy servicing. Advanced models incorporate pressure differential monitoring, allowing users to track filter condition and replacement timing. The technology accommodates various air volume requirements, from small residential units to large industrial installations. Quality vent filter systems contribute significantly to indoor air quality improvement, equipment protection, and compliance with environmental regulations. These filtration solutions play crucial roles in maintaining sterile environments, protecting sensitive equipment from contamination, and ensuring occupant health and safety across multiple industries and residential applications.