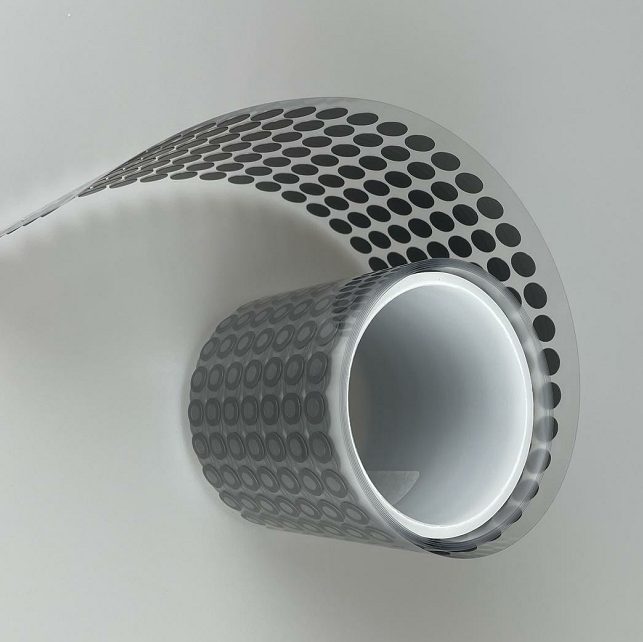

vent mesh

Vent mesh represents a sophisticated engineering solution designed to facilitate controlled airflow while maintaining structural integrity and protection against environmental factors. This specialized material combines advanced polymer technology with precision manufacturing techniques to create a barrier that allows gas exchange while preventing the ingress of contaminants, moisture, and particulates. The fundamental design of vent mesh incorporates microscopic pores strategically distributed across its surface, enabling selective permeability that meets specific industrial and commercial requirements. The manufacturing process involves careful selection of materials that can withstand various environmental conditions while maintaining consistent performance characteristics over extended periods. Modern vent mesh products utilize high-performance polymers, expanded metals, or composite materials that offer superior durability compared to traditional filtration methods. The pore structure is engineered to achieve optimal balance between breathability and protection, ensuring that internal pressure equalization occurs efficiently without compromising the integrity of enclosed systems. Applications for vent mesh span numerous industries, including electronics enclosures, automotive components, medical devices, and industrial equipment housings. In electronic applications, vent mesh prevents moisture accumulation that could damage sensitive circuitry while allowing thermal expansion and contraction to occur naturally. Automotive manufacturers integrate vent mesh into headlight assemblies, transmission housings, and battery compartments to maintain proper pressure levels and prevent condensation buildup. The medical device industry relies on vent mesh for sterile packaging applications where gas sterilization must penetrate materials while maintaining sterile barriers. Industrial equipment manufacturers use vent mesh in pump housings, gear boxes, and hydraulic systems to prevent pressure buildup that could lead to seal failure or performance degradation. The technological advancement in vent mesh design has led to customizable solutions that address specific performance requirements, including varying pore sizes, material compositions, and surface treatments that enhance functionality for targeted applications.