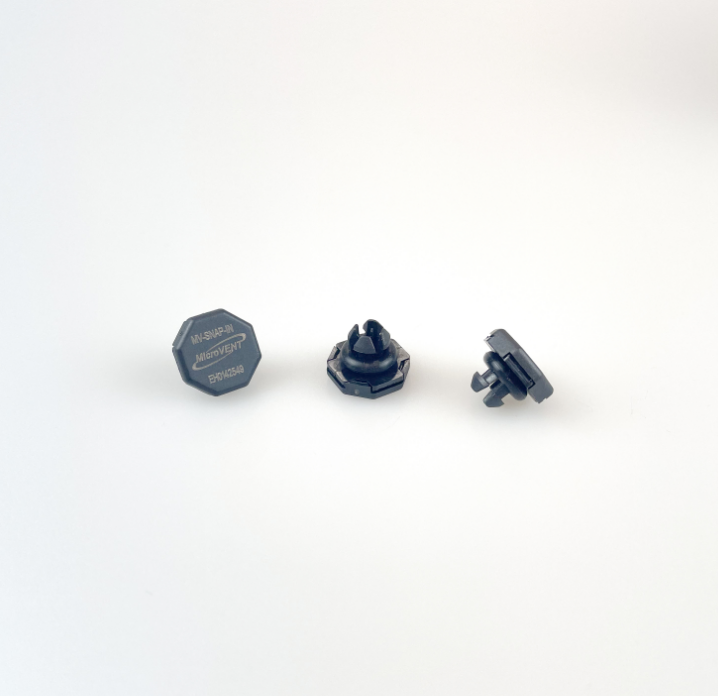

gas release bolt

The gas release bolt represents a sophisticated engineering solution designed to provide controlled pressure relief in critical industrial applications. This specialized fastener combines the structural integrity of conventional bolting systems with advanced pressure management capabilities, making it an essential component in high-pressure environments. The gas release bolt functions as both a mechanical fastener and a safety device, incorporating precision-engineered channels or valves that allow for the controlled discharge of pressurized gases when predetermined thresholds are reached. The primary function of a gas release bolt centers on maintaining system safety while preserving operational efficiency. These bolts are manufactured using high-grade materials such as stainless steel, carbon steel, or specialized alloys that can withstand extreme temperatures and corrosive environments. The technological features include precision-machined threads, integrated sealing mechanisms, and calibrated release ports that ensure consistent performance under varying operational conditions. The gas release bolt design incorporates multiple safety features, including pressure-sensitive components that activate automatically when system pressures exceed safe operating limits. This automated response capability eliminates the need for manual intervention during emergency situations, significantly reducing response time and potential safety risks. Applications for gas release bolts span numerous industries, including oil and gas processing, chemical manufacturing, power generation, and aerospace systems. In petrochemical facilities, these bolts serve critical roles in pipeline connections, pressure vessel assemblies, and processing equipment where sudden pressure variations could pose significant safety hazards. The gas release bolt also finds extensive use in steam generation systems, where thermal expansion and pressure fluctuations require precise control mechanisms. Manufacturing facilities utilize these specialized bolts in reactor vessels, distillation columns, and storage tanks where volatile substances are processed or stored. The aerospace industry employs gas release bolts in fuel systems, hydraulic assemblies, and pressurized cabin components where reliability and precision are paramount to operational safety and performance standards.