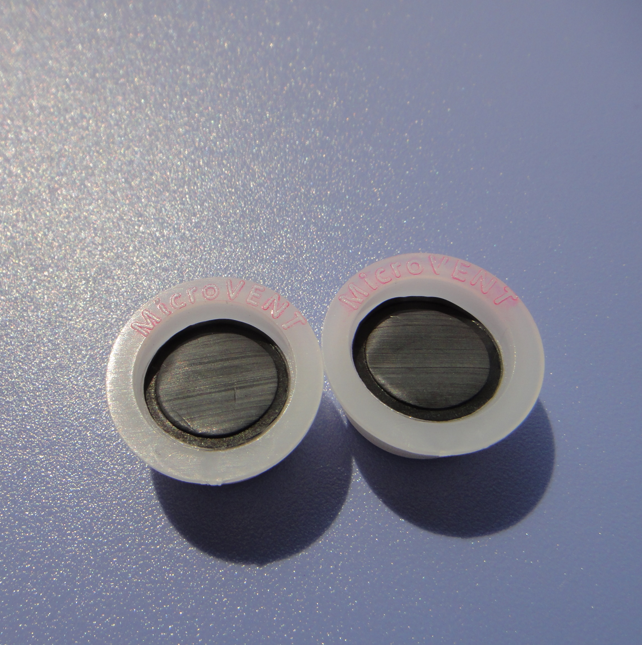

Advanced Sealing Technology for Ultimate Water Protection

The waterproof press fit valve incorporates cutting-edge sealing technology that sets new industry standards for moisture protection and system reliability. This sophisticated sealing system employs multiple independent barriers working in concert to prevent water infiltration under even the most challenging conditions. The primary sealing mechanism features precision-molded elastomeric rings manufactured from high-performance materials that maintain flexibility and sealing force across extreme temperature ranges. These primary seals are strategically positioned to create the first line of defense against water penetration while accommodating normal system pressures and thermal expansion. The secondary sealing system provides backup protection through integrated gasket assemblies that activate when primary seals experience unusual stress or wear. This redundant approach ensures continuous protection even if one sealing element becomes compromised during operation. The waterproof press fit valve's sealing technology undergoes rigorous testing protocols that simulate decades of real-world conditions in accelerated timeframes. These tests include pressure cycling, temperature shock, chemical exposure, and vibration resistance to validate long-term performance reliability. The advanced materials used in seal construction resist degradation from common industrial chemicals, oils, and cleaning agents that might compromise conventional sealing solutions. Environmental sealing capabilities extend beyond water protection to include dust, debris, and contaminate exclusion that could affect valve operation or system cleanliness. The sealing system's self-energizing design increases sealing force as system pressure rises, ensuring optimal protection under varying operational conditions. This intelligent response mechanism prevents seal extrusion and maintains consistent protection without requiring manual adjustments or external energy sources. Installation of the waterproof press fit valve's sealing system requires no special preparation or additional sealing compounds, reducing installation complexity and potential error sources. The integrated design eliminates interfaces between separate sealing components that could create leak paths or assembly difficulties. Quality control measures ensure each waterproof press fit valve meets stringent sealing performance criteria before shipment, providing customers with confidence in system reliability and reduced warranty concerns.