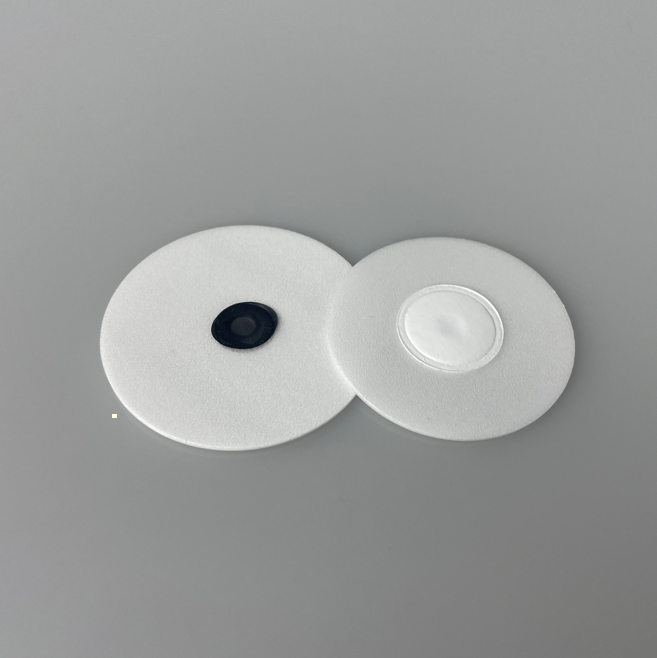

vent cap seal

A vent cap seal represents a critical component designed to protect ventilation systems while maintaining optimal airflow performance. This specialized sealing solution serves as a barrier between outdoor elements and internal ventilation infrastructure, ensuring reliable operation across diverse environmental conditions. The primary function of a vent cap seal involves preventing moisture infiltration, debris accumulation, and pest intrusion while allowing necessary air circulation. Modern vent cap seal designs incorporate advanced materials that withstand temperature fluctuations, UV radiation, and chemical exposure. The technological framework of these seals includes precision-engineered profiles that create tight seals around vent openings without compromising airflow efficiency. Installation typically involves secure mounting mechanisms that ensure long-term stability and maintenance accessibility. The vent cap seal construction utilizes weather-resistant materials such as EPDM rubber, silicone compounds, or specialized polymers that maintain flexibility across temperature ranges. These materials resist cracking, shrinking, and degradation that commonly affect inferior sealing solutions. Applications span residential, commercial, and industrial sectors where ventilation protection remains essential. HVAC systems, exhaust fans, roof vents, and specialized equipment ventilation all benefit from properly installed vent cap seal systems. The design considerations include compatibility with various vent configurations, mounting surface types, and environmental exposure levels. Quality vent cap seal products undergo rigorous testing to verify performance standards including water resistance, wind resistance, and thermal cycling capabilities. Manufacturing processes ensure consistent dimensional accuracy and material properties that guarantee reliable performance throughout the expected service life. Professional installation recommendations emphasize proper surface preparation, correct seal positioning, and appropriate fastening methods to maximize effectiveness and longevity.