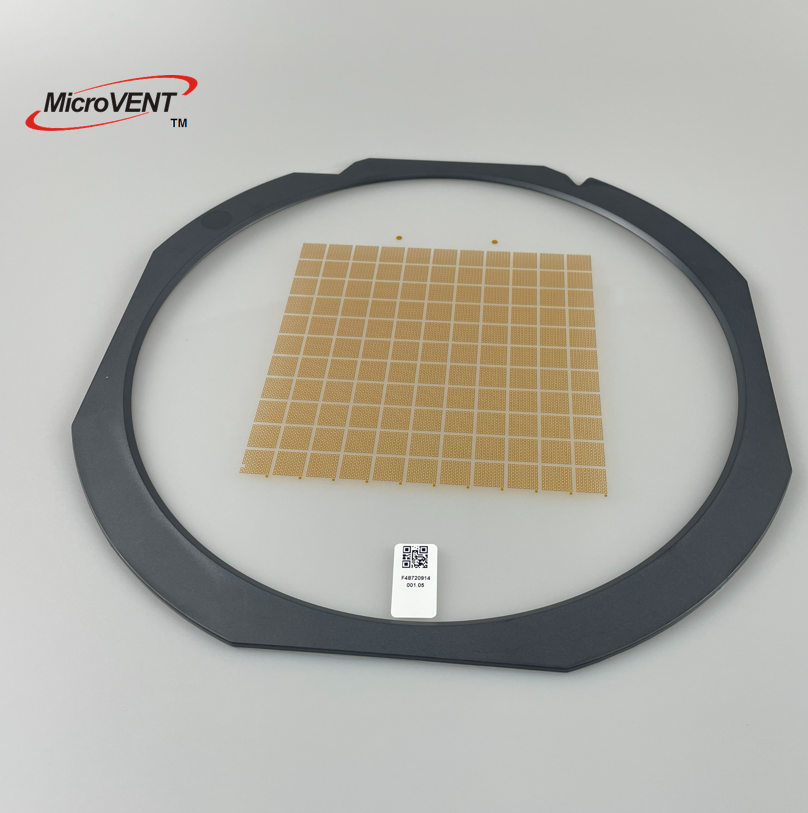

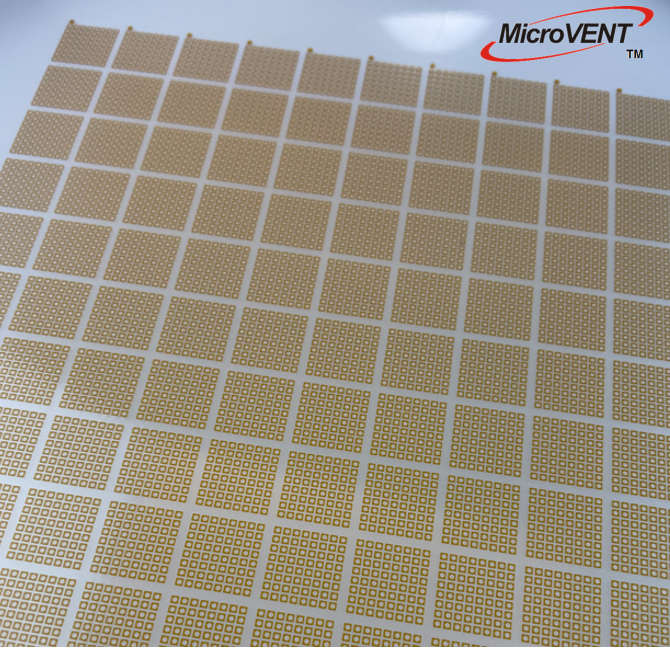

mems protective membrane

The mems protective membrane represents a revolutionary advancement in microelectromechanical systems technology, serving as a critical barrier that safeguards delicate MEMS components from environmental hazards and operational stresses. This sophisticated protective layer acts as the first line of defense for sensitive microdevices, ensuring their longevity and optimal performance across diverse applications. The mems protective membrane is engineered using advanced materials and precision manufacturing techniques to create an ultra-thin yet robust barrier that maintains the integrity of underlying MEMS structures. Its primary functions encompass moisture resistance, chemical protection, mechanical shielding, and thermal stability, making it indispensable for modern microelectronic devices. The technological features of the mems protective membrane include exceptional adhesion properties, controlled permeability, and compatibility with various substrate materials. These membranes are typically fabricated using specialized coating processes that ensure uniform thickness and consistent coverage across complex three-dimensional MEMS geometries. The applications of mems protective membrane span multiple industries, including automotive sensors, medical devices, consumer electronics, aerospace systems, and industrial automation equipment. In automotive applications, these protective membranes enable reliable operation of pressure sensors, accelerometers, and gyroscopes under harsh conditions including temperature fluctuations, humidity exposure, and chemical contamination. Medical device manufacturers rely on mems protective membrane technology to ensure biocompatibility and long-term stability of implantable sensors and diagnostic equipment. The membrane's ability to maintain selective permeability while blocking harmful substances makes it particularly valuable in healthcare applications where patient safety is paramount. Consumer electronics benefit from mems protective membrane integration through improved device reliability and extended operational lifespans, particularly in smartphones, tablets, and wearable devices that face daily exposure to environmental challenges.