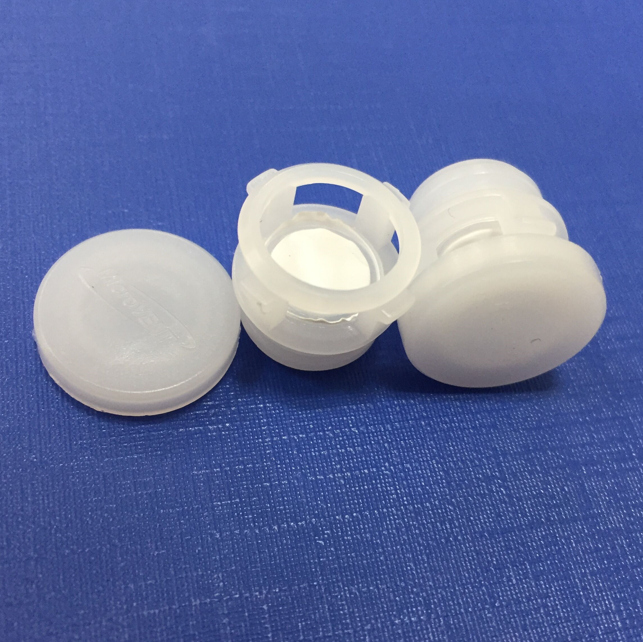

fertilizer vent bolt

The fertilizer vent bolt represents a critical component in modern agricultural equipment, specifically designed to regulate pressure and prevent contamination in fertilizer application systems. This specialized hardware serves as both a safety mechanism and efficiency enhancer for farming operations. The fertilizer vent bolt incorporates advanced engineering principles to maintain optimal pressure levels within fertilizer tanks and application equipment, ensuring consistent and reliable performance during critical planting seasons. Its primary function revolves around controlled venting of excess pressure while preventing moisture, debris, and contaminants from entering the fertilizer storage systems. The technological framework of this fertilizer vent bolt includes precision-manufactured threading, corrosion-resistant materials, and carefully calibrated venting mechanisms that respond to specific pressure thresholds. These components work together to create a reliable pressure relief system that protects expensive fertilizer application equipment from damage caused by over-pressurization or vacuum conditions. Agricultural operations benefit significantly from implementing fertilizer vent bolt systems across their equipment fleet, as these components directly impact operational efficiency and equipment longevity. The applications for fertilizer vent bolt technology span various agricultural sectors, including row crop farming, specialty crop production, and large-scale commercial operations. Modern fertilizer vent bolt designs incorporate weather-resistant sealing systems that maintain effectiveness across diverse environmental conditions, from humid coastal regions to arid agricultural zones. The engineering specifications of each fertilizer vent bolt are carefully matched to specific equipment requirements, ensuring optimal performance for different types of fertilizer application systems and storage configurations.