Modern smart speakers demand exceptional audio performance while maintaining protection against dust, moisture, and environmental contaminants. Traditional mesh solutions often fall short of meeting these dual requirements, leading manufacturers to seek more advanced protective technologies. Acoustic vents represent a breakthrough in audio device protection, offering superior sound transmission while providing robust environmental sealing capabilities that standard mesh cannot match.

The evolution of smart speaker technology has driven significant improvements in protective component design. Engineers now recognize that audio quality and device longevity are equally important factors in consumer satisfaction. Standard mesh materials, while cost-effective, present limitations in both acoustic transparency and long-term durability that can compromise device performance over time.

Superior Sound Transmission Technology

Enhanced Acoustic Transparency

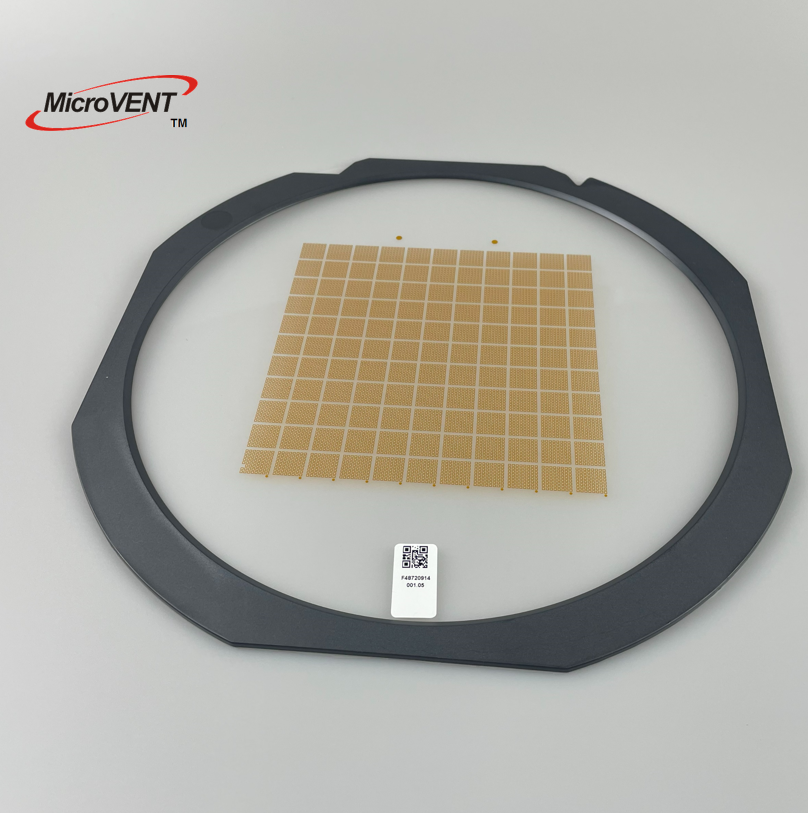

MicroVENT technology delivers exceptional acoustic transparency through precisely engineered microporous membrane structures. Unlike conventional mesh materials that create acoustic impedance and frequency distortion, these advanced protective membranes maintain consistent sound quality across the entire audio spectrum. The microscopic pore structure allows unrestricted airflow while preserving the integrity of low-frequency bass response and high-frequency clarity that audiophiles demand.

Laboratory testing demonstrates that MicroVENT membranes achieve acoustic transmission rates exceeding 95% across critical frequency ranges. This performance level ensures that smart speakers equipped with these protective components deliver the full dynamic range intended by audio engineers. Traditional mesh solutions typically exhibit significant acoustic attenuation, particularly in mid-range frequencies where human hearing sensitivity peaks.

Frequency Response Optimization

The engineered pore geometry of advanced acoustic vents enables precise control over frequency response characteristics. Sound engineers can optimize membrane specifications to complement specific driver configurations and enclosure designs. This level of customization allows manufacturers to achieve target acoustic signatures while maintaining consistent protection standards across product lines.

Comparative analysis reveals that standard mesh materials introduce unwanted resonances and phase shifts that degrade audio fidelity. MicroVENT technology eliminates these acoustic anomalies through controlled porosity distribution and membrane thickness optimization. The result is cleaner sound reproduction with improved stereo imaging and reduced harmonic distortion.

Advanced Environmental Protection

Moisture Resistance Performance

Smart speakers face constant exposure to humidity variations and potential liquid contamination in typical household environments. Acoustic vents provide superior moisture protection through hydrophobic membrane treatments that actively repel water while maintaining air permeability. This dual functionality ensures consistent performance in kitchens, bathrooms, and outdoor installation scenarios where standard mesh would quickly fail.

The molecular-level engineering of protective membranes creates a selective barrier that blocks liquid water penetration while allowing water vapor transmission. This breathability prevents internal condensation buildup that could damage sensitive electronic components. Standard mesh offers no moisture resistance, leaving internal circuitry vulnerable to corrosion and short-circuit failures.

Dust and Particle Filtration

Advanced acoustic vent technology incorporates multi-layer filtration systems that capture airborne particles without restricting acoustic performance. The microscopic pore structure effectively blocks dust, pollen, and other contaminants that would otherwise accumulate on speaker drivers and internal components. This protection extends device lifespan while maintaining optimal audio output over extended operational periods.

Particle size analysis demonstrates that MicroVENT membranes filter contaminants down to sub-micron levels while preserving acoustic transparency. Standard mesh materials lack this fine filtration capability, allowing harmful particles to penetrate and degrade internal components. The superior protection offered by advanced acoustic vents translates directly into reduced maintenance requirements and improved long-term reliability.

Manufacturing and Integration Advantages

Design Flexibility Benefits

Modern acoustic vent technology offers unprecedented design flexibility that enables innovative smart speaker architectures. The thin profile and moldable characteristics of advanced membranes allow integration into complex geometric forms without compromising structural integrity. This versatility empowers industrial designers to create sleeker, more aesthetically pleasing products while maintaining superior performance standards.

The adhesive mounting systems developed for acoustic vents provide secure attachment to various substrate materials including plastics, metals, and composites. Installation processes are streamlined compared to traditional mesh mounting methods, reducing assembly time and improving manufacturing consistency. Quality control procedures can easily verify proper membrane installation through visual and pressure testing protocols.

Cost-Effectiveness Analysis

While initial material costs for advanced acoustic vents may exceed standard mesh pricing, the total cost of ownership demonstrates significant economic advantages. Reduced warranty claims, extended product lifespan, and improved customer satisfaction metrics justify the investment in premium protective technology. Manufacturing efficiency gains through simplified assembly processes further offset material cost differentials.

Market research indicates that consumers increasingly prioritize audio quality and device durability when selecting smart speakers. Products equipped with superior protective technology command premium pricing while maintaining competitive market positions. The enhanced performance characteristics delivered by advanced acoustic vents support brand differentiation strategies that drive revenue growth and customer loyalty.

Performance Testing and Validation

Standardized Testing Protocols

Comprehensive testing methodologies validate the superior performance characteristics of advanced acoustic vent technology through rigorous evaluation protocols. Acoustic transmission measurements utilize precision instrumentation to quantify frequency response, phase coherence, and harmonic distortion parameters. Environmental testing simulates real-world conditions including temperature cycling, humidity exposure, and contamination resistance.

Accelerated aging studies demonstrate the long-term stability of membrane performance under continuous operational stress. These evaluations include acoustic property retention, physical integrity assessment, and protective function verification over extended test periods. Results consistently show superior durability compared to conventional mesh solutions across all evaluation criteria.

Quality Assurance Standards

Manufacturing quality control procedures ensure consistent performance across production batches through statistical process monitoring and incoming material verification. Advanced inspection techniques including microscopic examination and automated defect detection identify potential quality issues before products reach customers. These comprehensive quality systems support the reliable performance expectations associated with premium acoustic vent technology.

Certification compliance with international standards demonstrates the professional-grade quality of advanced protective membranes. Testing laboratories verify performance claims through independent evaluation protocols that validate acoustic transmission, environmental protection, and durability specifications. This third-party validation provides confidence for manufacturers integrating these components into high-value audio products.

Future Technology Developments

Smart Membrane Integration

Emerging developments in acoustic vent technology include smart membrane capabilities that adapt to environmental conditions and usage patterns. Sensor integration enables real-time monitoring of acoustic performance, environmental exposure, and membrane condition status. These intelligent systems provide predictive maintenance alerts and performance optimization recommendations that maximize device lifespan and user satisfaction.

Research initiatives explore programmable membrane characteristics that allow dynamic adjustment of acoustic properties and protective functions. Variable porosity control systems could optimize performance for specific acoustic signatures or environmental conditions. These advanced capabilities represent the next generation of protective technology for premium audio applications.

Sustainable Material Innovation

Environmental sustainability considerations drive development of eco-friendly membrane materials that maintain superior performance while reducing environmental impact. Biodegradable polymer formulations and recycled content integration support corporate sustainability initiatives without compromising functional requirements. These innovations align with growing consumer demand for environmentally responsible technology products.

Life cycle analysis of advanced acoustic vents demonstrates favorable environmental profiles compared to traditional mesh solutions. Extended product lifespan and reduced replacement frequency contribute to overall sustainability benefits that support green manufacturing initiatives. The superior durability of advanced membranes reduces electronic waste generation while maintaining optimal device performance throughout extended operational periods.

FAQ

How do acoustic vents improve smart speaker sound quality compared to standard mesh

Acoustic vents utilize precisely engineered microporous membranes that maintain over 95% acoustic transparency across critical frequency ranges, while standard mesh creates acoustic impedance and frequency distortion. The advanced membrane structure eliminates unwanted resonances and phase shifts that degrade audio fidelity, resulting in cleaner sound reproduction with improved stereo imaging and reduced harmonic distortion.

What environmental protection advantages do MicroVENT membranes provide

MicroVENT technology offers superior moisture resistance through hydrophobic treatments that repel water while maintaining air permeability, preventing internal condensation and component corrosion. The multi-layer filtration system captures dust and particles down to sub-micron levels, protecting sensitive internal components from contamination that standard mesh cannot block, significantly extending device lifespan.

Are advanced acoustic vents cost-effective for smart speaker manufacturers

Despite higher initial material costs, advanced acoustic vents provide significant economic advantages through reduced warranty claims, extended product lifespan, and improved customer satisfaction. Manufacturing efficiency gains from simplified assembly processes offset material cost differentials, while premium performance characteristics support brand differentiation strategies that enable competitive pricing and increased customer loyalty.

How is the performance of acoustic vent membranes validated and tested

Comprehensive testing protocols evaluate acoustic transmission, environmental protection, and durability through standardized measurements and accelerated aging studies. Quality assurance procedures include statistical process monitoring, microscopic examination, and automated defect detection, while third-party certification validates performance claims against international standards, ensuring consistent professional-grade quality across production batches.

Table of Contents

- Superior Sound Transmission Technology

- Advanced Environmental Protection

- Manufacturing and Integration Advantages

- Performance Testing and Validation

- Future Technology Developments

-

FAQ

- How do acoustic vents improve smart speaker sound quality compared to standard mesh

- What environmental protection advantages do MicroVENT membranes provide

- Are advanced acoustic vents cost-effective for smart speaker manufacturers

- How is the performance of acoustic vent membranes validated and tested

EN

EN

AR

AR

CS

CS

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

ID

ID

VI

VI

TH

TH

TR

TR

MS

MS