Moisture management remains one of the most critical challenges facing modern industrial applications, electronic devices, and protective equipment. When water vapor and condensation accumulate in enclosed systems, they can cause devastating damage to sensitive components, reduce equipment lifespan, and compromise performance reliability. The breakthrough solution lies in advanced eptfe membrane technology, which provides superior vapor transmission while maintaining complete waterproof protection. This innovative material has revolutionized how industries approach moisture control, offering unprecedented performance in demanding environments where traditional solutions fail to deliver adequate results.

Understanding the Science Behind eptfe Membrane Technology

Microporous Structure and Vapor Permeability

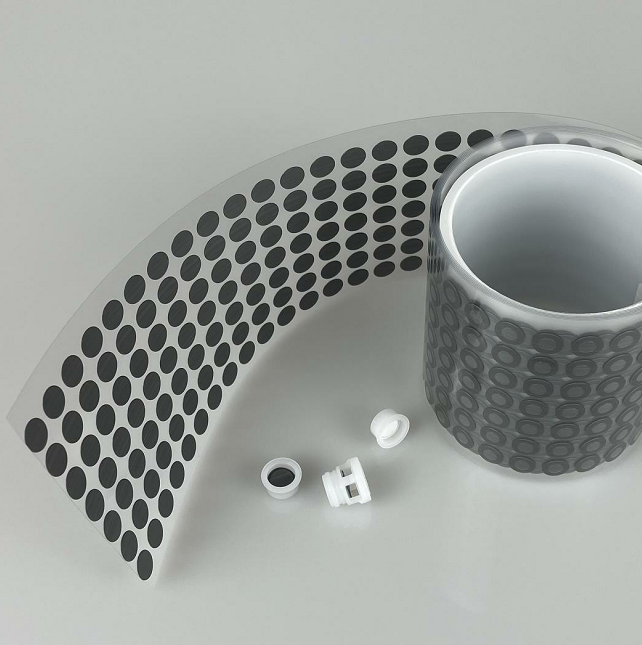

The fundamental principle behind eptfe membrane effectiveness lies in its unique microporous structure, which features billions of microscopic pores per square inch. These pores are approximately 20,000 times smaller than a water droplet but 700 times larger than a water vapor molecule. This precise size differential allows water vapor to pass through freely while preventing liquid water penetration. The eptfe membrane achieves this selective permeability through a controlled stretching process that creates a network of interconnected nodes and fibrils, forming the characteristic porous matrix that defines its exceptional performance characteristics.

The vapor transmission rate of eptfe membrane significantly exceeds that of conventional materials, enabling rapid moisture evacuation from enclosed spaces. This superior breathability prevents the accumulation of humidity that typically leads to condensation formation and subsequent damage. The membrane's hydrophobic nature ensures that water molecules in vapor form can traverse the material while maintaining an impermeable barrier to liquid water, creating an ideal solution for applications requiring both protection and ventilation.

Chemical Resistance and Durability Properties

Beyond its moisture management capabilities, eptfe membrane exhibits exceptional chemical resistance that makes it suitable for harsh industrial environments. The fluoropolymer composition provides inherent stability against acids, bases, solvents, and other aggressive chemicals commonly encountered in industrial applications. This chemical inertness ensures that the membrane maintains its performance characteristics over extended periods, even when exposed to corrosive substances that would degrade alternative materials.

The durability of eptfe membrane extends to temperature extremes, with operational capability ranging from -200°C to +260°C without significant performance degradation. This thermal stability, combined with excellent UV resistance and mechanical strength, ensures long-term reliability in challenging environments. The membrane's ability to withstand repeated flexing, vibration, and thermal cycling makes it ideal for dynamic applications where other materials might fail prematurely.

Industrial Applications and Moisture Control Solutions

Electronic Equipment Protection

Electronic devices and control systems face constant threats from moisture infiltration, which can cause short circuits, corrosion, and component failure. The implementation of eptfe membrane venting solutions provides effective protection while maintaining necessary pressure equalization. As temperature fluctuations occur during normal operation, the membrane allows air to flow freely while blocking water ingress, preventing the formation of damaging condensation inside sensitive electronic enclosures.

The telecommunications industry has widely adopted eptfe membrane technology for protecting outdoor equipment installations. Cell towers, junction boxes, and network infrastructure components require reliable moisture protection while maintaining thermal management capabilities. The membrane's ability to facilitate heat dissipation through vapor transmission while preventing water damage has proven essential for maintaining network reliability in diverse climatic conditions.

Automotive and Transportation Industries

Modern vehicles incorporate numerous electronic systems that require protection from moisture while allowing for thermal expansion and contraction. The eptfe membrane serves as a critical component in automotive lighting assemblies, preventing fogging and condensation that could impair visibility and safety. Engine control units, transmission systems, and battery compartments all benefit from the selective permeability that allows vapor escape while maintaining liquid water protection.

The aerospace industry relies heavily on eptfe membrane technology for protecting avionics and flight-critical systems from moisture damage during altitude changes and extreme weather conditions. The membrane's ability to maintain performance at high altitudes and low atmospheric pressures makes it indispensable for aircraft applications where conventional venting methods prove inadequate.

Advantages Over Traditional Moisture Management Methods

Superior Performance Compared to Conventional Vents

Traditional mechanical vents and drainage systems often fail to provide adequate moisture protection while introducing potential failure points and maintenance requirements. The eptfe membrane eliminates these concerns by providing passive, maintenance-free operation that continuously manages moisture levels without mechanical components that could wear out or become blocked. This reliability advantage translates to reduced maintenance costs and improved system uptime across various applications.

Conventional moisture barriers typically create sealed environments that trap humidity, leading to condensation problems during temperature cycling. The breathable nature of eptfe membrane prevents this issue by allowing continuous vapor exchange while maintaining liquid water protection. This dynamic balance ensures optimal internal conditions regardless of external environmental changes, providing superior protection compared to static barrier methods.

Cost-Effectiveness and Long-Term Value

While the initial investment in eptfe membrane technology may exceed that of traditional solutions, the long-term value proposition becomes compelling when considering reduced maintenance requirements and extended equipment lifespan. The membrane's durability and consistent performance eliminate the need for frequent replacements or system interventions, resulting in lower total cost of ownership over the equipment's operational life.

The prevention of moisture-related damage through effective eptfe membrane implementation significantly reduces warranty claims and field failures. Industries that have adopted this technology report substantial reductions in equipment downtime and repair costs, demonstrating clear return on investment for applications where moisture control is critical to operational success.

Installation and Design Considerations

Proper Sizing and Configuration

Successful eptfe membrane implementation requires careful consideration of several factors including enclosure volume, expected temperature differentials, and environmental exposure conditions. The membrane area must be appropriately sized to handle the vapor transmission requirements while maintaining adequate protection against liquid water ingress. Engineering calculations should account for worst-case scenarios to ensure reliable performance under all operating conditions.

The positioning and orientation of eptfe membrane vents significantly impact their effectiveness in moisture management applications. Proper installation guidelines must be followed to ensure optimal performance, including consideration of mounting angle, drainage provisions, and protection from direct water spray or submersion. Professional installation practices maximize the membrane's performance potential while ensuring long-term reliability.

Integration with Existing Systems

Retrofitting existing equipment with eptfe membrane venting solutions requires careful assessment of current moisture management provisions and their effectiveness. The integration process often involves replacing inadequate conventional vents with properly sized membrane assemblies while ensuring compatibility with existing enclosure designs and environmental sealing requirements.

New system designs can incorporate eptfe membrane technology from the initial development phase, allowing for optimized placement and sizing that maximizes moisture management effectiveness. This approach typically results in better overall performance and more cost-effective implementation compared to retrofit applications where design constraints may limit optimal membrane utilization.

Quality Standards and Testing Protocols

Performance Verification Methods

The verification of eptfe membrane performance requires comprehensive testing protocols that evaluate both vapor transmission rates and liquid water resistance under various conditions. Standardized test methods ensure consistent quality and performance across different manufacturers and applications. These tests include pressure differential measurements, temperature cycling evaluations, and long-term durability assessments that confirm the membrane's ability to maintain specified performance characteristics throughout its expected service life.

Quality assurance programs for eptfe membrane products typically include batch testing, statistical process control, and ongoing performance monitoring to ensure consistent quality delivery. These measures provide confidence in the membrane's ability to perform as specified in critical applications where failure could result in significant consequences or costs.

Industry Certification Requirements

Various industries have established specific certification requirements for eptfe membrane products used in critical applications. These certifications often include testing to industry-specific standards that address unique environmental challenges and performance requirements. Compliance with these standards ensures that the membrane technology meets the demanding requirements of specialized applications while providing documented evidence of performance capability.

The documentation and traceability requirements associated with certified eptfe membrane products provide valuable assurance for applications where quality and reliability are paramount. This certification framework supports consistent performance expectations and facilitates specification compliance across diverse industrial applications.

FAQ

How long does eptfe membrane typically last in outdoor applications

The lifespan of eptfe membrane in outdoor applications typically ranges from 10 to 20 years, depending on environmental conditions and exposure factors. The membrane's exceptional UV resistance and chemical stability contribute to this extended service life, even in challenging outdoor environments. Regular inspection and proper installation practices can help maximize the membrane's operational lifespan while maintaining consistent moisture management performance.

Can eptfe membrane handle high-pressure applications

Yes, eptfe membrane can be designed to handle significant pressure differentials while maintaining its selective permeability characteristics. The membrane's mechanical strength allows it to withstand substantial pressure loads without compromising its microporous structure or performance capabilities. Specific pressure ratings depend on membrane thickness, support structure design, and application requirements, with custom solutions available for demanding high-pressure applications.

What maintenance is required for eptfe membrane systems

One of the primary advantages of eptfe membrane technology is its minimal maintenance requirements compared to mechanical venting systems. The membrane typically requires only periodic visual inspection to ensure the protective housing remains intact and free from physical damage. Unlike mechanical vents that may require cleaning or component replacement, the membrane itself is essentially maintenance-free during normal operation, contributing to reduced operational costs and improved reliability.

Is eptfe membrane suitable for food processing applications

Yes, eptfe membrane is well-suited for food processing applications due to its chemical inertness and FDA-approved material composition. The membrane's resistance to cleaning chemicals and sanitizing agents makes it ideal for environments requiring frequent washdown procedures. Its ability to maintain moisture control while preventing contamination ingress supports food safety requirements while protecting sensitive equipment from humidity-related damage in processing facilities.

EN

EN

AR

AR

CS

CS

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

ID

ID

VI

VI

TH

TH

TR

TR

MS

MS