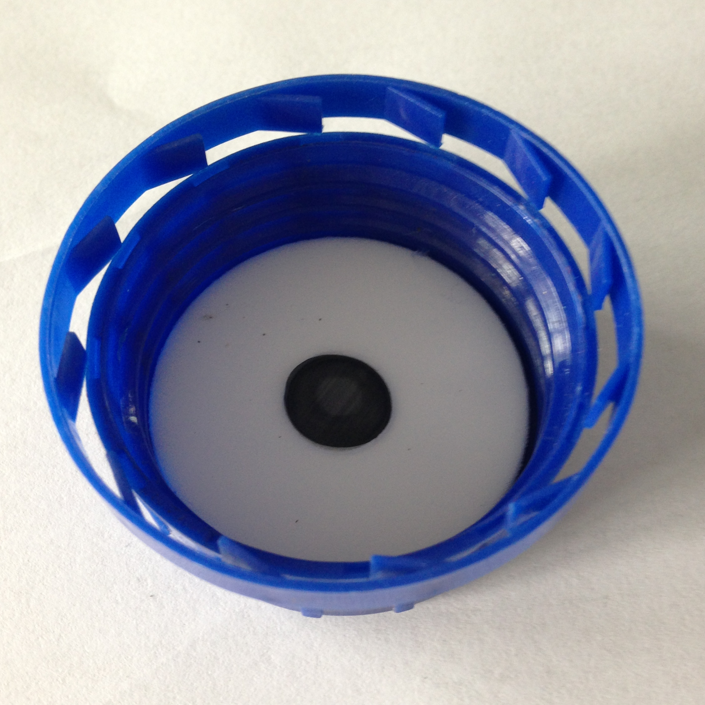

aliminium induction seal

The aluminium induction seal represents a revolutionary advancement in packaging technology, designed to provide superior product protection and tamper-evident security across various industries. This innovative sealing solution utilizes electromagnetic induction heating to create a hermetic bond between a specially formulated aluminium foil liner and container openings. The aluminium induction seal consists of multiple layers, including a heat-activated adhesive layer, an aluminium foil barrier, and a protective polymer coating that work together to deliver exceptional performance. The primary function of the aluminium induction seal involves creating an airtight, moisture-proof barrier that preserves product freshness, extends shelf life, and prevents contamination. When electromagnetic energy is applied through induction sealing equipment, the aluminium layer heats rapidly, activating the adhesive and forming a permanent bond with the container rim. This process occurs without direct contact, ensuring consistent seal quality and eliminating the risk of contamination during the sealing process. The technological features of aluminium induction seals include precise temperature control, uniform heat distribution, and compatibility with various container materials including glass, plastic, and metal. The aluminium foil component provides excellent barrier properties against oxygen, moisture, light, and other environmental factors that could compromise product integrity. Applications for aluminium induction seals span numerous industries, including pharmaceuticals, food and beverages, cosmetics, chemicals, and nutritional supplements. In pharmaceutical applications, these seals ensure medication safety and comply with stringent regulatory requirements. Food manufacturers rely on aluminium induction seals to maintain product freshness and prevent spoilage. The cosmetic industry utilizes these seals to preserve formulation stability and prevent product contamination. Chemical manufacturers benefit from the superior barrier properties that prevent leakage and maintain product quality during storage and transportation.