akustik eptfe yaması

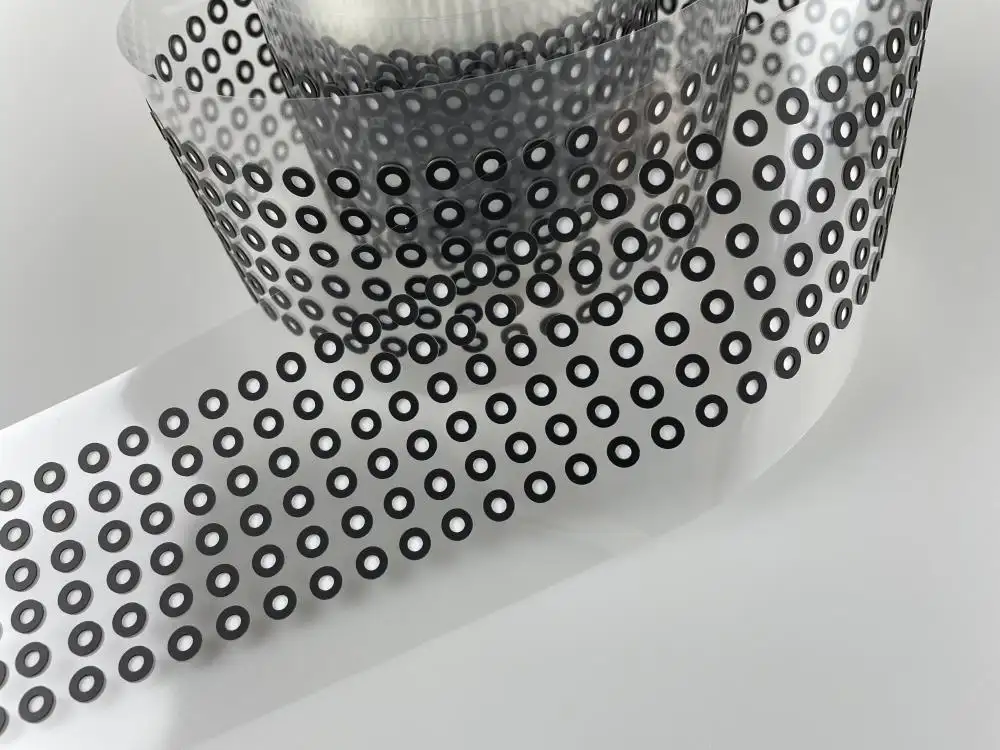

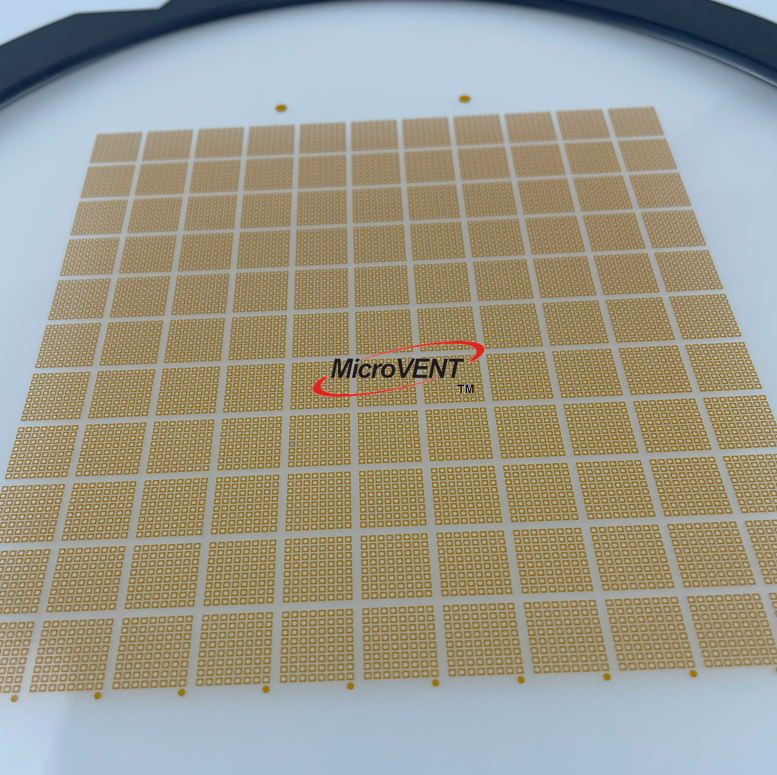

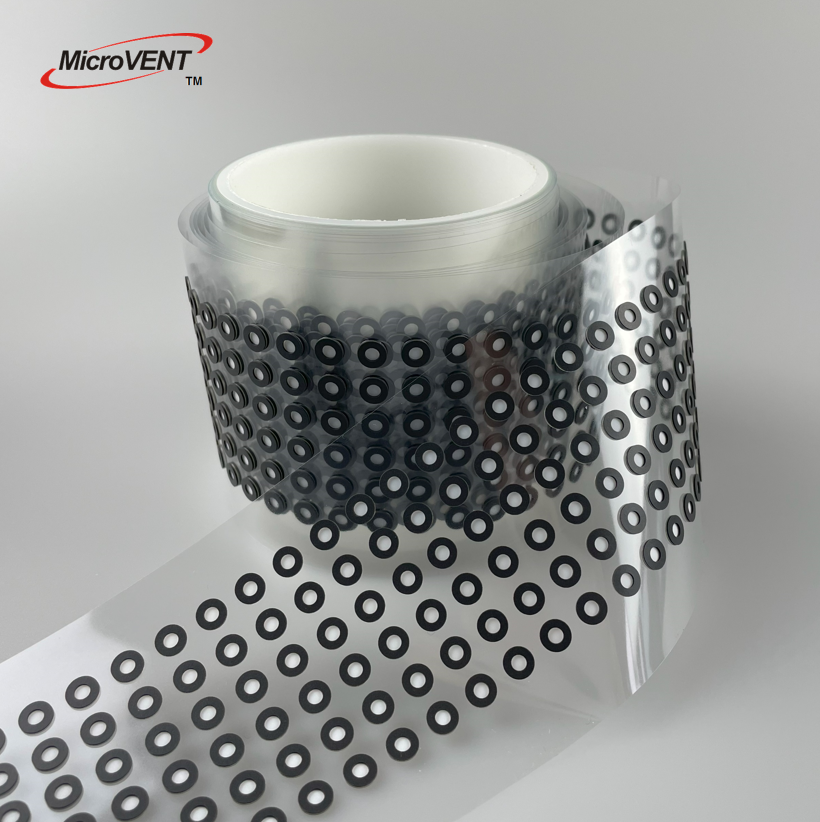

Akustik eptfe yama, genişletilmiş politetrafluoroetilenin olağanüstü özelliklerini özel akustik mühendisliği prensipleriyle birleştirerek ses yönetimi teknolojisinde devrim niteliğinde bir ilerleme temsil eder. Bu yenilikçi malzeme çözümü, hassas ses kontrolü, titreşim sönümleme ve akustik optimizasyonun temel gereklilik olduğu çeşitli uygulamalarda kritik bir bileşen görevi görür. Akustik eptfe yama, zorlu çevre koşullarında nefes alabilirlik ve dayanıklılığı korurken ses iletimini yöneten seçici bir bariyer olarak primarily işlev görür. Benzersiz mikro gözenekli yapısı, belirli frekans aralıklarının etkili bir şekilde filtrelenmesini ve zayıflamasını sağlarken kontrollü hava geçirgenliğine izin verir ve böylece karmaşık akustik uygulamalar için ideal bir seçim haline gelir. Akustik eptfe yamanın teknolojik temeli, özel akustik performans gereksinimlerini karşılamak üzere özelleştirilebilen dikkatle tasarlanmış gözenek yapısına sahip gelişmiş malzeme bileşiminde yatmaktadır. Bu malzeme, sıcaklık uçlarında, kimyasallara ve mekanik streslere karşı dikkate değer direnç göstererek zorlu çalışma ortamlarında uzun vadeli güvenilirlik sağlar. Yama tasarımı, farklı akustik özellikler için optimize edilmiş birden fazla özel eptfe membran katmanını içererek kompakt bir formda kapsamlı bir ses yönetimi sistemi oluşturur. Akustik eptfe yama uygulamaları otomotiv imalatı, havacılık mühendisliği, tüketici elektroniği, mimari akustik ve endüstriyel ekipman tasarımını içeren çok sayıda sektörde yer alır. Otomotiv uygulamalarında bu yamalar, gerekli havalandırmayı korurken istenmeyen gürültü iletimini azaltarak kabin konforunu artırır. Havacılık uygulamalarında ise malzeme, uçak içi gürültü azaltma ve iletişim sistemi optimizasyonu için kullanılır. Tüketici elektroniği, hassas bileşenleri korurken hoparlör performansını yönetme ve elektromanyetik girişimi azaltma konusundaki yamanın yeteneğinden faydalanır. Üretim süreci, istenen akustik özellikleri yaratırken yapısal bütünlüğü ve çevresel direnci koruyan hassas gerdirme ve katmanlama tekniklerini içerir.

EN

EN

AR

AR

CS

CS

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

ID

ID

VI

VI

TH

TH

TR

TR

MS

MS