membrane perméable au son

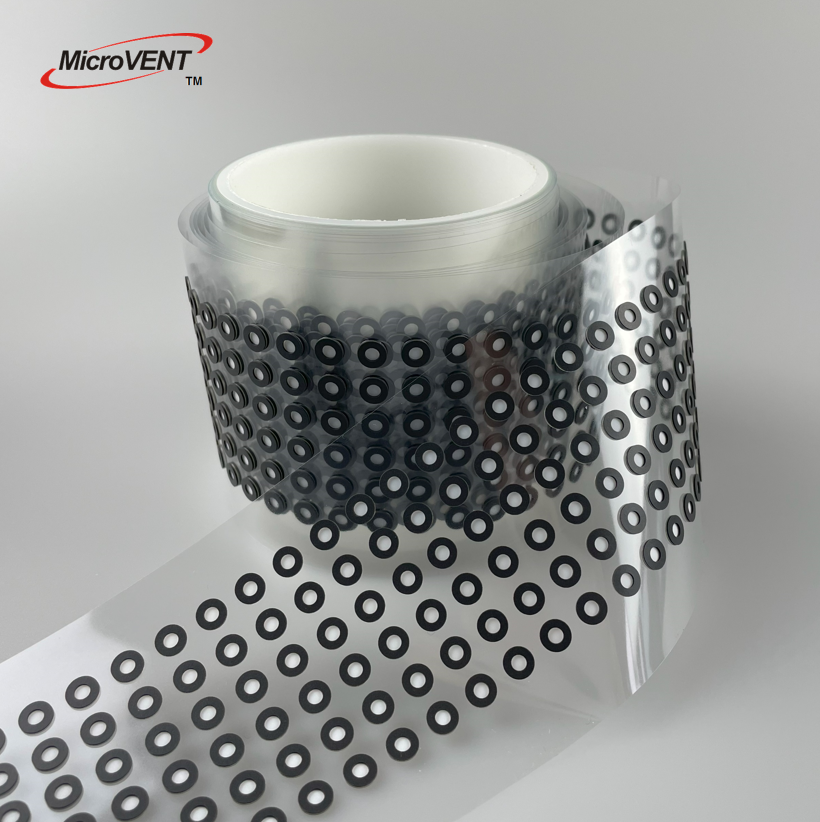

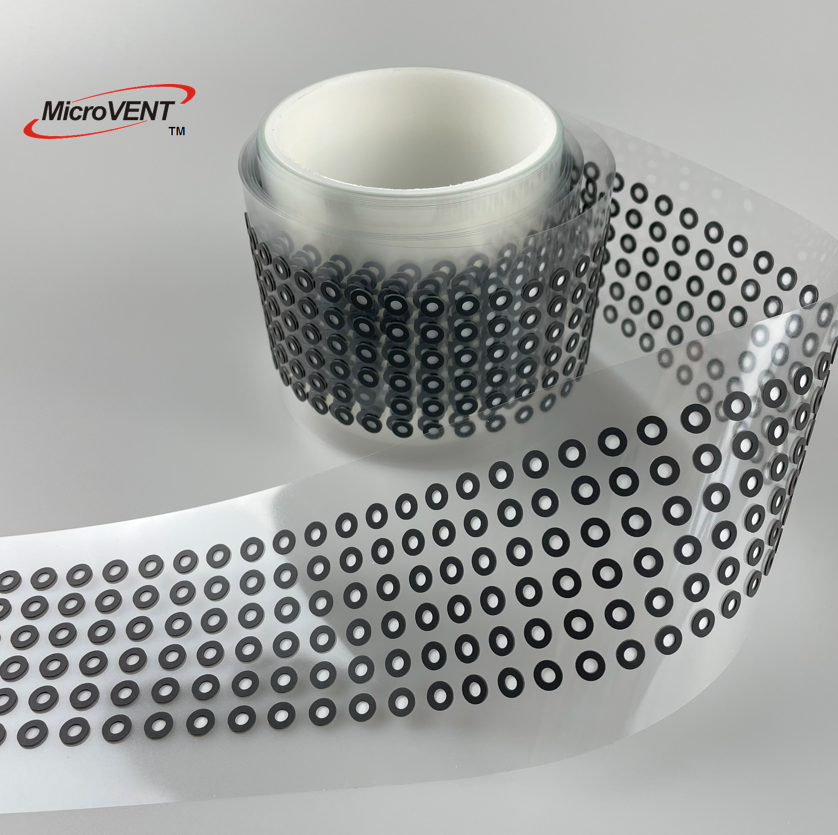

Une membrane perméable au son représente une solution innovante en ingénierie acoustique permettant une transmission contrôlée du son tout en préservant l'intégrité structurelle et la protection environnementale. Cette technologie avancée de matériaux allie perméabilité sélective et construction robuste, créant une barrière qui laisse passer certaines fréquences spécifiques tout en bloquant la pollution sonore indésirable. La membrane perméable au son fonctionne selon des principes acoustiques sophistiqués, utilisant des structures de pores et des compositions matérielles précisément conçues pour atteindre une performance optimale de filtration sonore. Les systèmes modernes de membranes perméables au son intègrent des technologies polymères de pointe et des motifs de perforation microscopiques pouvant être personnalisés selon des exigences acoustiques spécifiques. Ces membranes agissent comme des barrières sélectives, permettant la transmission naturelle des fréquences audio souhaitées tout en atténuant les niveaux de bruit excessifs ou nuisibles. Le fondement technologique de la conception des membranes perméables au son repose sur des sciences avancées des matériaux, intégrant des tissus spécialisés, des plastiques techniques et des matériaux composites capables de maintenir leur durabilité dans diverses conditions environnementales. La polyvalence d'installation rend les solutions à base de membranes perméables au son adaptées à des applications intérieures comme extérieures, allant de l'acoustique architecturale aux systèmes de contrôle du bruit industriel. La construction de la membrane comprend généralement plusieurs couches, chacune assurant des fonctions acoustiques et protectrices spécifiques, garantissant des performances et une fiabilité durables. Les procédés de fabrication des produits à base de membranes perméables au son impliquent des techniques d'ingénierie de précision qui maîtrisent la distribution de la taille des pores, la densité du matériau et les caractéristiques de surface afin d'obtenir les propriétés acoustiques souhaitées. Des mesures de contrôle qualité assurent une performance constante dans différentes conditions environnementales, plages de température et niveaux d'humidité. La technologie des membranes perméables au son continue de s'améliorer grâce à des initiatives de recherche et développement visant à optimiser la sélectivité acoustique, la durabilité et l'efficacité d'installation pour diverses applications commerciales.