The fertilizer industry faces unique packaging challenges that require specialized solutions to maintain product integrity during storage and transportation. A MicroVENT packaging liner represents an innovative approach to managing moisture, gas exchange, and pressure differentials within fertilizer containers. These advanced liners provide essential protection for fertilizer products while ensuring optimal performance throughout the supply chain. Understanding the specific functions and benefits of MicroVENT packaging liner technology helps manufacturers make informed decisions about their packaging strategies. The implementation of proper venting systems in fertilizer packaging directly impacts product quality, shelf life, and customer satisfaction across various agricultural applications.

Understanding MicroVENT Technology in Fertilizer Applications

Advanced Venting Mechanisms

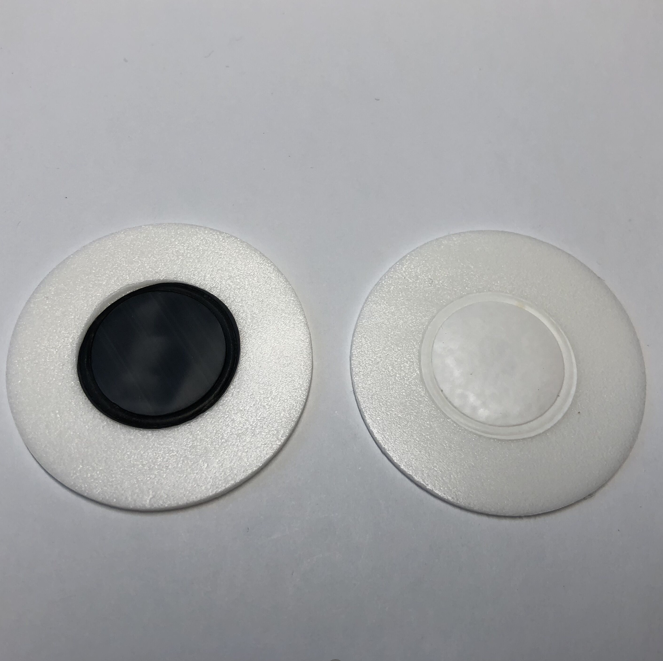

MicroVENT packaging liner systems utilize sophisticated microporous technology to create controlled gas exchange pathways within fertilizer containers. These microscopic vents allow gases to escape while preventing moisture ingress and contamination from external sources. The technology works by maintaining optimal pressure levels inside packaging, which prevents bag rupture and product spillage during handling and transport. This controlled venting mechanism is particularly crucial for fertilizers that undergo chemical reactions or gas generation during storage periods.

The engineering behind MicroVENT packaging liner design incorporates precise pore sizing and distribution patterns that respond to pressure differentials. When internal pressure builds up due to temperature changes or chemical processes, the vents automatically open to release excess gases. Conversely, when external pressure increases or temperatures drop, the vents remain sealed to prevent moisture infiltration. This dynamic response system ensures consistent product protection across varying environmental conditions commonly encountered in agricultural supply chains.

Material Science and Construction

The construction of MicroVENT packaging liner products involves advanced polymer engineering that balances permeability with durability requirements. These liners typically incorporate multiple layers of specialized materials, each serving specific protective functions. The outer layer provides mechanical strength and puncture resistance, while inner layers control gas transmission rates and chemical compatibility with fertilizer compounds. This multi-layer approach ensures comprehensive protection without compromising the liner's flexibility or installation ease.

Quality control measures in MicroVENT packaging liner manufacturing include rigorous testing of pore uniformity, material strength, and chemical resistance. Each batch undergoes verification processes to ensure consistent venting performance across temperature ranges and humidity levels. The materials selected for these liners must withstand exposure to various fertilizer chemistries, including acidic and alkaline compounds, without degradation or performance loss over extended storage periods.

Primary Functions in Fertilizer Protection

Moisture Control and Prevention

One of the most critical functions of a MicroVENT packaging liner in fertilizer applications involves moisture management and humidity control. Fertilizer products are highly susceptible to moisture absorption, which can lead to caking, nutrient degradation, and reduced application effectiveness. The venting technology creates a controlled environment that maintains optimal moisture levels while preventing condensation buildup inside packaging containers.

The moisture protection capabilities of MicroVENT packaging liner systems extend beyond simple barrier functions. These liners actively regulate humidity levels by allowing moisture vapor to escape when internal humidity exceeds optimal thresholds. This active moisture management prevents the formation of hot spots and reduces the risk of chemical reactions that could compromise fertilizer quality. The result is improved product stability and extended shelf life for various fertilizer formulations.

Gas Exchange Regulation

Proper gas exchange regulation represents another essential function of MicroVENT packaging liner technology in fertilizer storage systems. Many fertilizer products generate gases during storage, either through natural decomposition processes or chemical reactions between components. Without adequate venting, these gases can create dangerous pressure buildup that leads to package failure or safety hazards. The controlled venting provided by MicroVENT packaging liner systems safely manages these gas emissions while maintaining package integrity.

The gas exchange capabilities also help maintain optimal oxygen levels within fertilizer packages. Some fertilizer formulations require specific atmospheric conditions to remain stable and effective. The MicroVENT packaging liner technology allows for controlled oxygen transmission that supports product stability while preventing oxidation reactions that could degrade nutrient content. This precise gas management contributes significantly to maintaining fertilizer efficacy throughout storage and distribution cycles.

Performance Benefits for Fertilizer Manufacturers

Enhanced Product Stability

The implementation of MicroVENT packaging liner systems delivers measurable improvements in fertilizer product stability across various storage conditions. Temperature fluctuations during transportation and warehousing can cause significant stress on fertilizer products, leading to physical and chemical changes that reduce effectiveness. These advanced liners help buffer against temperature-induced pressure changes, maintaining consistent internal conditions that preserve product quality.

Long-term stability testing demonstrates that fertilizers protected by MicroVENT packaging liner technology retain their nutrient content and physical properties significantly longer than products stored in conventional packaging. This enhanced stability translates directly into reduced product returns, improved customer satisfaction, and stronger brand reputation in competitive agricultural markets. Manufacturers benefit from lower warranty claims and reduced inventory losses due to product degradation.

Operational Efficiency Improvements

MicroVENT packaging liner implementation contributes to improved operational efficiency throughout fertilizer production and distribution processes. The reduced risk of package failure means fewer disruptions during handling, transport, and storage operations. Workers experience fewer safety incidents related to package rupture or product spillage, creating safer working conditions and reducing cleanup costs.

The reliability of MicroVENT packaging liner systems also enables more efficient inventory management strategies. Products can be stored for longer periods without quality concerns, allowing manufacturers to optimize production schedules and reduce rush orders. This operational flexibility helps balance supply and demand more effectively while minimizing storage costs and logistics complexity.

Application-Specific Advantages

Granular Fertilizer Protection

Granular fertilizers present unique packaging challenges due to their physical structure and tendency to generate dust during handling. MicroVENT packaging liner technology addresses these challenges by providing controlled venting that prevents dust accumulation while maintaining granule integrity. The precise pore sizing in these liners allows fine particles to settle naturally while preventing external contamination from entering the package.

The protection offered by MicroVENT packaging liner systems extends to preventing granule breakdown and fines generation during storage and transport. By maintaining stable internal conditions and reducing mechanical stress on granules, these liners help preserve the physical characteristics that ensure proper fertilizer application and nutrient distribution in field conditions.

Liquid Fertilizer Considerations

While primarily designed for solid fertilizer applications, MicroVENT packaging liner technology can also benefit liquid fertilizer storage systems. The venting capabilities help manage vapor pressure buildup in liquid fertilizer containers, particularly important for formulations containing volatile components. This pressure management prevents container deformation and reduces the risk of leakage or spillage during handling operations.

The chemical resistance properties of MicroVENT packaging liner materials make them suitable for use with various liquid fertilizer chemistries. The inert nature of the liner materials prevents chemical reactions with fertilizer components while maintaining venting functionality over extended storage periods. This compatibility ensures consistent protection regardless of fertilizer formulation complexity.

Installation and Maintenance Considerations

Proper Installation Techniques

Successful implementation of MicroVENT packaging liner systems requires attention to proper installation procedures and quality control measures. The installation process must ensure complete coverage of vulnerable areas while maintaining the integrity of venting mechanisms. Proper sealing techniques prevent bypass leakage that could compromise the controlled atmosphere within fertilizer packages.

Training programs for installation personnel emphasize the importance of handling MicroVENT packaging liner materials carefully to avoid damage to microporous structures. Installation quality directly impacts performance, making standardized procedures essential for consistent results across different production facilities and packaging operations.

Long-Term Performance Monitoring

Ongoing performance monitoring ensures that MicroVENT packaging liner systems continue to provide optimal protection throughout their service life. Regular inspection schedules help identify potential issues before they affect product quality or package integrity. Monitoring protocols typically include visual inspections, pressure testing, and periodic sampling to verify continued effectiveness.

Performance data collection from MicroVENT packaging liner applications provides valuable feedback for optimizing system design and installation procedures. This data helps manufacturers refine their packaging strategies and identify opportunities for further improvements in product protection and operational efficiency.

FAQ

How does a MicroVENT packaging liner prevent fertilizer caking?

A MicroVENT packaging liner prevents fertilizer caking by controlling moisture levels and humidity within the package. The microporous venting technology allows excess moisture vapor to escape while preventing external moisture from entering. This controlled environment maintains optimal humidity levels that prevent the moisture absorption and crystal formation that leads to caking in fertilizer products.

What maintenance is required for MicroVENT packaging liner systems?

MicroVENT packaging liner systems require minimal maintenance once properly installed. Regular visual inspections should be conducted to check for physical damage or contamination of venting areas. The liners are designed to be maintenance-free during normal operation, but periodic performance verification through pressure testing or gas exchange measurements can help ensure continued effectiveness.

Can MicroVENT packaging liner technology work with all fertilizer types?

MicroVENT packaging liner technology is compatible with most fertilizer types, including granular, powdered, and blended formulations. The chemical-resistant materials used in these liners can withstand exposure to various fertilizer chemistries. However, specific compatibility should be verified for highly reactive or corrosive fertilizer formulations to ensure optimal performance and longevity.

How does temperature affect MicroVENT packaging liner performance?

MicroVENT packaging liner performance is designed to remain stable across typical storage and transportation temperature ranges. The venting mechanisms automatically adjust to temperature-induced pressure changes, opening to release excess pressure during heating and sealing to prevent moisture ingress during cooling. This temperature responsiveness helps maintain consistent internal conditions regardless of external temperature fluctuations commonly encountered in fertilizer supply chains.

EN

EN

AR

AR

CS

CS

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

ID

ID

VI

VI

TH

TH

TR

TR

MS

MS