ما هي الأنواع المختلفة من فتحات التهوية الصوتية MicroVENT® المتوفرة؟

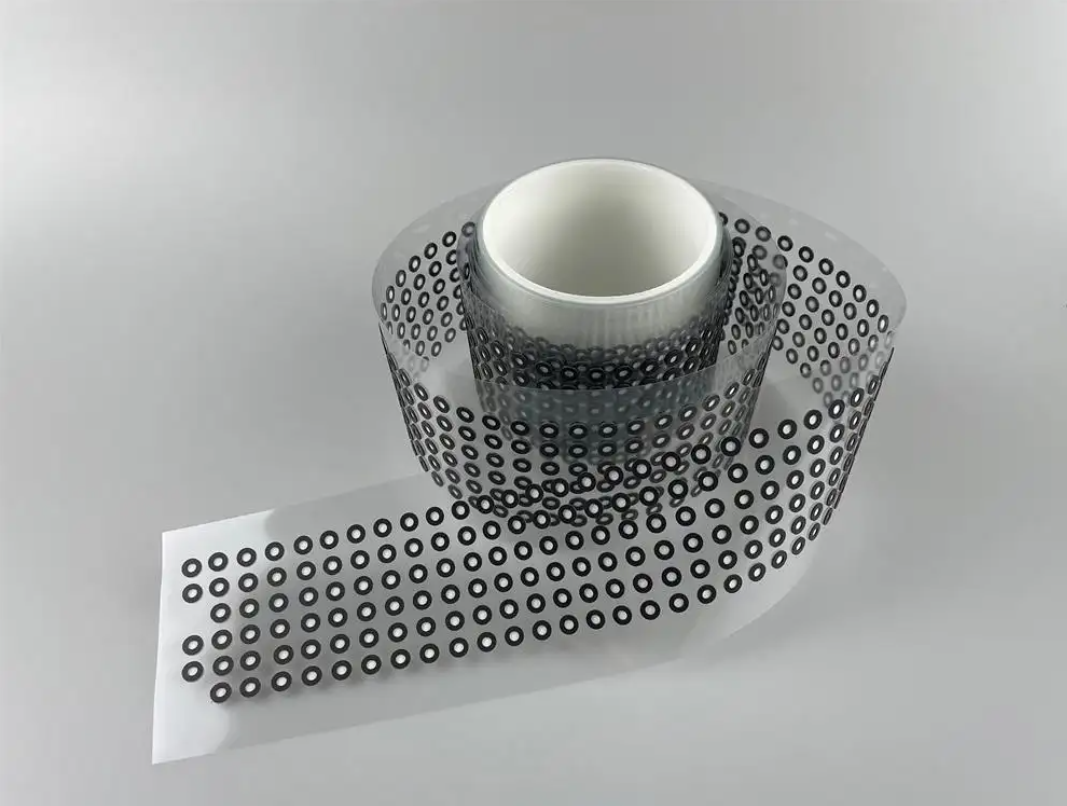

فهم تقنية MicroVENT® لفتحات الصوت ومبادئ تصميم غشاء ePTFE الأساسية: يتميز غشاء البوليمر المُوسّع (ePTFE) بمسامية ملحوظة، مما يجعله مادة مثالية لتطبيقات فتحات الصوت...

عرض المزيد

EN

EN

AR

AR

CS

CS

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

ID

ID

VI

VI

TH

TH

TR

TR

MS

MS