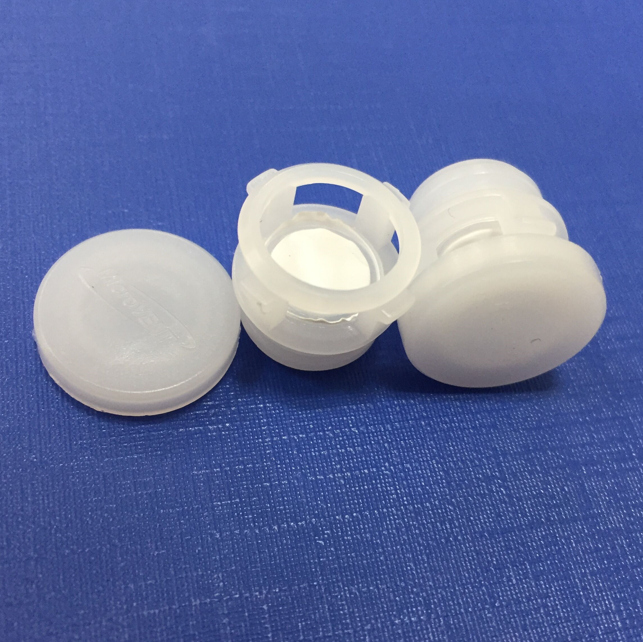

packaging bottle cap

The packaging bottle cap represents a critical component in modern packaging systems, serving as the primary barrier between products and external environments. This essential element functions as a protective seal that maintains product integrity, prevents contamination, and ensures consumer safety across diverse industries including beverages, pharmaceuticals, cosmetics, and food products. The packaging bottle cap operates through multiple mechanisms including screw-on threading, snap-fit designs, and pressure-sensitive systems that create airtight seals. Advanced manufacturing techniques employ high-grade materials such as polypropylene, polyethylene, aluminum, and specialized composite materials that resist chemical reactions and environmental degradation. Contemporary packaging bottle cap technology incorporates tamper-evident features, child-resistant mechanisms, and smart sensing capabilities that monitor product freshness. The structural design of each packaging bottle cap includes precision-engineered threads, gasket systems, and locking mechanisms that ensure reliable closure performance. Quality control processes verify torque specifications, seal integrity, and dimensional accuracy to meet stringent industry standards. Modern packaging bottle cap production utilizes injection molding, compression molding, and thermoforming processes that achieve consistent dimensional tolerances and surface finishes. Environmental considerations drive innovations in recyclable materials and biodegradable alternatives that maintain functional performance while reducing ecological impact. The packaging bottle cap market continues evolving with smart technology integration, including NFC chips and QR codes that enable product authentication and consumer engagement. These technological advances enhance brand protection while providing valuable data collection opportunities for manufacturers and retailers seeking to understand consumer behavior patterns.