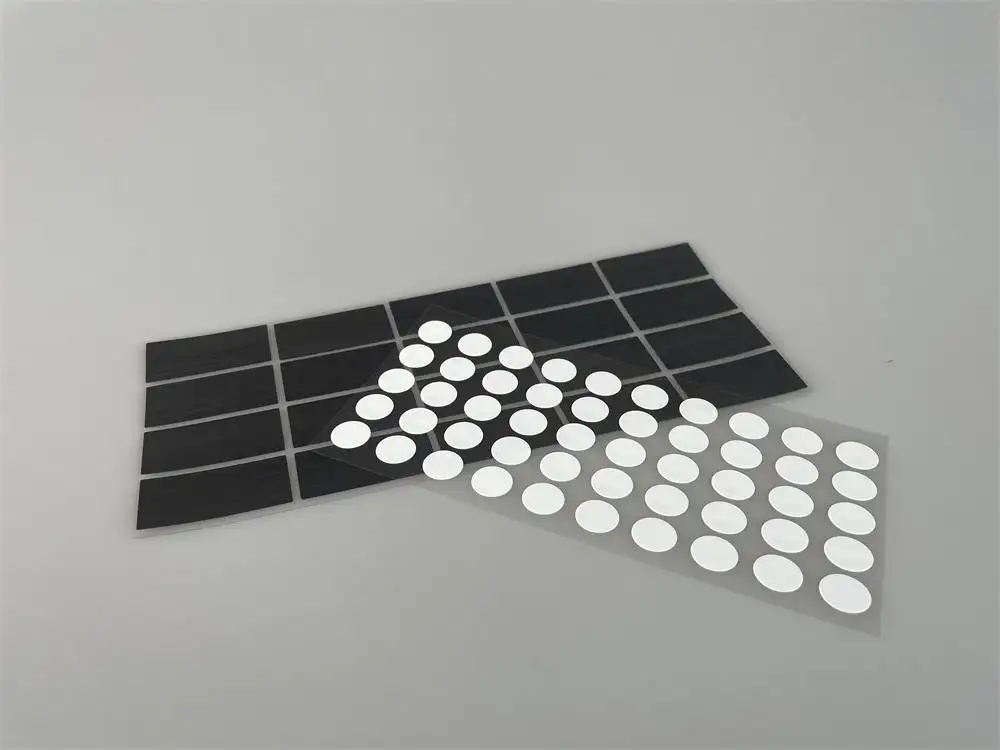

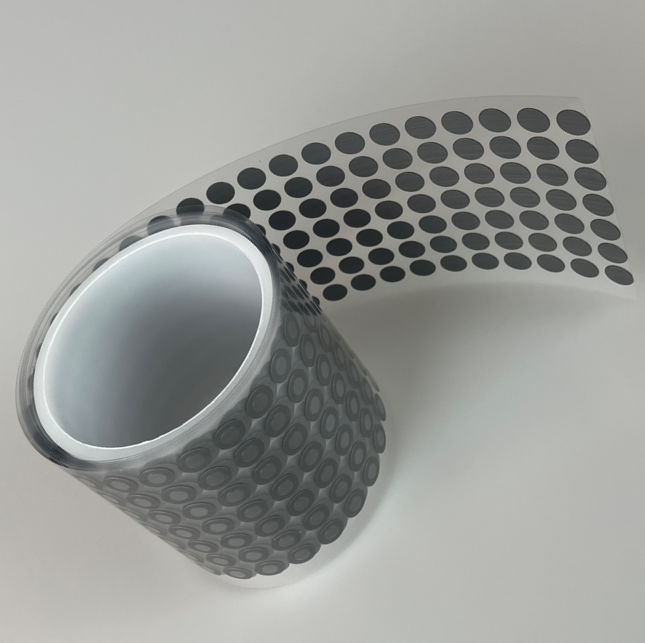

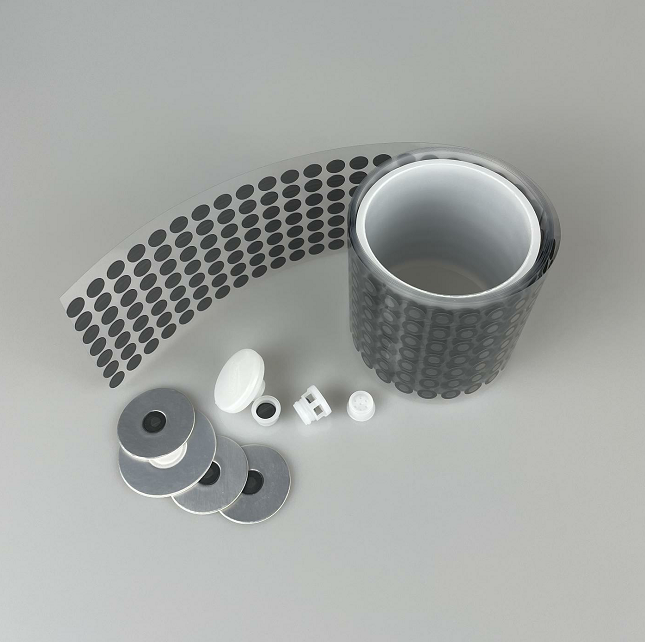

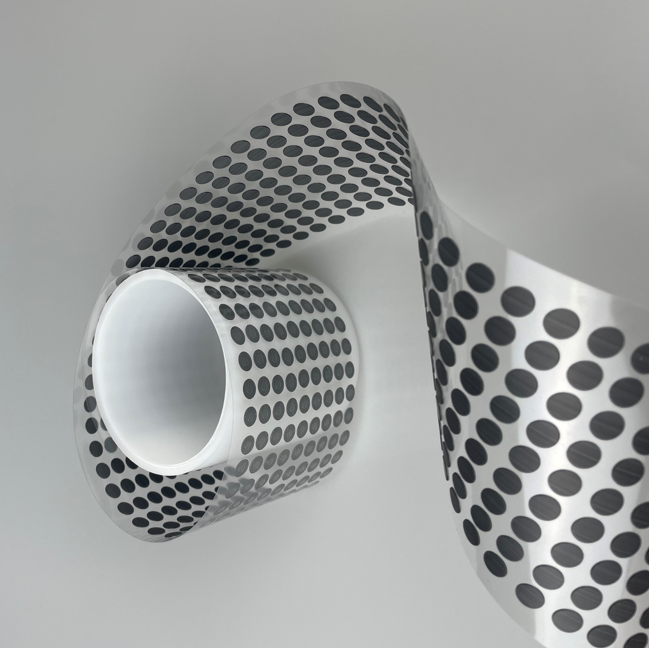

ช่องระบายอากาศแบบเสียบแน่น

ช่องระบายอากาศแบบอัดแน่นถือเป็นความก้าวหน้าอย่างปฏิวัติวงการในเทคโนโลยีการระบายอากาศ ที่ได้รับการออกแบบเพื่อให้เกิดการไหลเวียนของอากาศอย่างมีประสิทธิภาพในหลากหลายการใช้งานด้านอุตสาหกรรมและเชิงพาณิชย์ องค์ประกอบพิเศษสำหรับการระบายอากาศเหล่านี้ใช้กลไกการติดตั้งที่ทันสมัย ซึ่งช่วยกำจัดความจำเป็นในการใช้อุปกรณ์ยึดติดแบบเดิม กาว หรือฮาร์ดแวร์ติดตั้งที่ซับซ้อน การออกแบบแบบอัดแน่นทำให้สามารถติดตั้งช่องระบายอากาศเหล่านี้ได้อย่างมั่นคงเพียงแค่กดเข้าไปในรูที่เจาะไว้ล่วงหน้า สร้างการปิดผนึกที่รวดเร็วและเชื่อถือได้ ซึ่งรักษาประสิทธิภาพสูงสุดได้อย่างต่อเนื่องในระยะยาว ฟังก์ชันหลักของช่องระบายอากาศแบบอัดแน่นอยู่ที่ความสามารถในการควบคุมแรงดันอากาศ ควบคุมระดับความชื้น และช่วยให้เกิดการไหลเวียนของอากาศอย่างเหมาะสมภายในพื้นที่ปิด องค์ประกอบเหล่านี้ผลิตจากวัสดุที่ผ่านการออกแบบอย่างแม่นยำ เพื่อต้านทานการกัดกร่อน การเปลี่ยนแปลงของอุณหภูมิ และความเครียดจากสิ่งแวดล้อม ขณะที่ยังคงรักษารูปร่างและความแข็งแรงของโครงสร้างไว้ได้ เทคโนโลยีทางสถาปัตยกรรมรวมถึงสารประกอบโพลิเมอร์ขั้นสูงและกลไกการปิดผนึกเฉพาะที่รับประกันประสิทธิภาพการทำงานที่สม่ำเสมอภายใต้เงื่อนไขการใช้งานที่แตกต่างกัน ช่องระบายอากาศแบบอัดแน่นเหมาะอย่างยิ่งสำหรับการใช้งานหลากหลาย เช่น ตู้อิเล็กทรอนิกส์ ชิ้นส่วนยานยนต์ เครื่องจักรอุตสาหกรรม และอุปกรณ์ทางทะเล ความยืดหยุ่นของมันทำให้สามารถใช้งานได้ทั้งในร่มและกลางแจ้ง โดยที่โซลูชันการระบายอากาศแบบดั้งเดิมอาจไม่เพียงพอหรือใช้งานไม่สะดวก ปรัชญาการออกแบบเน้นขั้นตอนการติดตั้งที่ใช้งานง่าย ซึ่งช่วยลดต้นทุนแรงงานและเวลาในการติดตั้งอย่างมากเมื่อเทียบกับทางเลือกแบบเดิม กระบวนการผลิตใช้เทคนิคการฉีดขึ้นรูปที่ทันสมัย ซึ่งให้ความแม่นยำของขนาดที่สม่ำเสมอและผิวสัมผัสที่มีคุณภาพสูง มาตรฐานการควบคุมคุณภาพรับประกันว่าช่องระบายอากาศแบบอัดแน่นทุกชิ้นจะผ่านมาตรฐานด้านความทนทาน ความต้านทานสภาพอากาศ และความเชื่อถือได้ในการใช้งานอย่างเข้มงวด การออกแบบแบบโมดูลาร์ช่วยให้สามารถปรับแต่งได้ง่ายเพื่อตอบสนองความต้องการเฉพาะของการใช้งาน รวมถึงขนาด วัสดุ และข้อกำหนดด้านประสิทธิภาพที่หลากหลาย ประเด็นด้านสิ่งแวดล้อมมีบทบาทสำคัญในการพัฒนาโซลูชันการระบายอากาศเหล่านี้ โดยแบบจำลองจำนวนมากใช้วัสดุที่สามารถรีไซเคิลได้และกระบวนการผลิตที่เป็นมิตรต่อสิ่งแวดล้อม ซึ่งช่วยลดผลกระทบต่อสิ่งแวดล้อม พร้อมทั้งยังคงมอบคุณสมบัติการใช้งานที่ยอดเยี่ยม

EN

EN

AR

AR

CS

CS

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

ID

ID

VI

VI

TH

TH

TR

TR

MS

MS