Превосходная материалоинженерия и долговечность

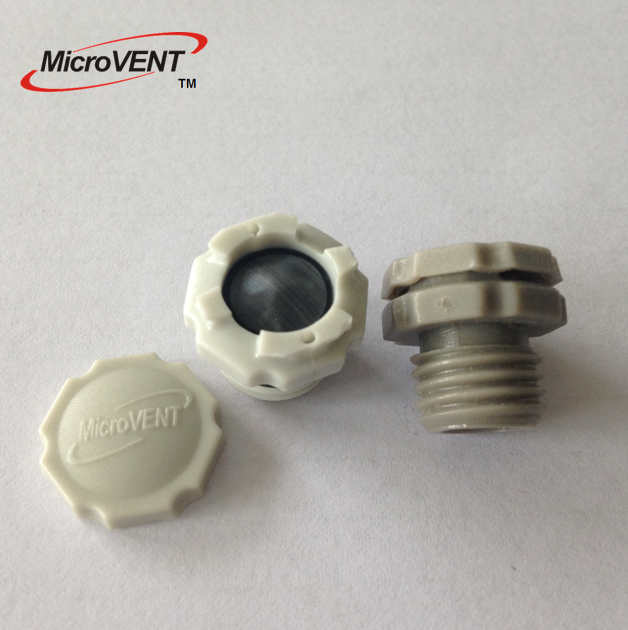

Винт-болт с микроотверстием использует передовые принципы инженерии материалов, чтобы обеспечить исключительную долговечность и продолжительный срок службы, превосходящие традиционные решения для крепежа. Сплавы высшего качества проходят специальную термическую обработку для достижения оптимального соотношения прочности и веса при сохранении точных размерных допусков, необходимых для эффективной функции вентиляции. Технологии поверхностной обработки включают передовые покрытия и гальванические слои, обеспечивающие превосходную устойчивость к коррозии, химическую совместимость и защиту от износа в сложных эксплуатационных условиях. Процесс выбора материала учитывает множество факторов, включая предел прочности при растяжении, сопротивление усталости, характеристики теплового расширения и экологическую совместимость, чтобы гарантировать надежную работу в различных областях применения. Контроль качества производства включает строгие протоколы испытаний, такие как металлографический анализ, проверка размеров и подтверждение рабочих характеристик, для обеспечения стабильных свойств материала на всех этапах производственной партии. Винт-болт с микроотверстием демонстрирует исключительную устойчивость к гальванической коррозии, коррозионному растрескиванию под напряжением и водородному охрупчиванию, которые часто поражают стандартные крепёжные элементы в агрессивных средах. Тепловая стабильность позволяет винту-болту с микроотверстием сохранять целостность конструкции и эффективность вентиляции в экстремальных температурных диапазонах без деградации или изменения размеров. Свойства химической стойкости обеспечивают безопасную работу в агрессивных средах, включая морскую воду, кислоты, щелочи и органические растворители, без снижения производительности или компрометирования безопасности. Испытания на усталость показывают превосходные возможности при циклических нагрузках: винты-болты с микроотверстием демонстрируют увеличенный срок службы при многократных приложениях напряжений по сравнению с традиционными аналогами. Инженерные материалы обеспечивают повышенную устойчивость к вибрациям, предотвращая ослабление и поддерживая надёжное соединение в условиях высокой вибрации, таких как автомобильная и аэрокосмическая отрасли. Размерная стабильность гарантирует постоянную эффективность вентиляции на протяжении всего срока эксплуатации винта-болта с микроотверстием, исключая снижение производительности со временем. Эксплуатационные испытания подтверждают надёжную работу в экстремальных условиях, включая воздействие ультрафиолетового излучения, циклы влажности и загрязнение химическими веществами.

EN

EN

AR

AR

CS

CS

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

ID

ID

VI

VI

TH

TH

TR

TR

MS

MS